Power is a key element in ensuring a fire pump works in an emergency situation.

Learning Objectives

- Learn the basics of designing electrical power system to feed the fire pump system.

- Understand the basic principle behind fire pump electrical power systems.

- Know the codes that pertain to providing power to fire pumps, chiefly NFPA 20 and NFPA 70, and know how NFPA 1, NFPA 101, NFPA 110, NFPA 5000, IBC, and IFC pertain to fire pump designs.

There are few pieces of equipment in a building more critical than the fire pump. Although it will hopefully never run for its intended purpose, when there is that dreaded fire in a building, the fire pump must work. A failure in the fire pump system endangers people’s lives. Because of the critical nature of a piece of equipment that rarely runs, the engineer designing the system must fully understand the codes and standards, and use his engineering judgment to provide a robust system that will operate during the most critical of times.

When designing the power supply for a facility fire pump, there are specific code requirements that apply and must be followed. The two main code sections for providing power to fire pumps are NFPA 20: Standard for the Installation of Stationary Pumps for Fire Protection Chapter 9 and NFPA 70: National Electric Code (NEC) Article 695. Although there is some overlap between the two codes, there are differences in the scopes of the two articles, as they both state right up front. Article 695 covers the requirements for the electric installation. NFPA 20 covers the fire pump selection and installation. NFPA 20 also covers reliability concerns for the power supplies, which is where most of the overlap with Article 695 occurs. Fortunately, Article 695 references NFPA 20 extensively, minimizing the code-hopping that engineers are so fond of.

Engineering coordination

Before we start discussing technical details, the first step to designing the power for a fire pump system is to coordinate with the architect and fire protection engineer on whether a fire pump is required, and if so, what size will it be. The architect will review the building type and number of occupants to determine if a sprinkler system and fire pump are required. He or she also will review the locally adopted codes such as the International Building Code (IBC), International Fire Code (IFC), NFPA 5000: Building Construction and Safety Code, NFPA 101: Life Safety Code, and any other specifications, local codes, or amendments to the codes.

Specific references to fire pump requirements are sprinkled throughout these codes, and almost all reference NFPA 20. IBC Chapter 913 is dedicated to fire pump requirements and deals essentially with protection of the fire pump room within the building. In Chapter 403.4.9 the IBC defines electric fire pumps as emergency loads. IFC Chapter 913 deals specifically with fire pumps and the room requirements. NFPA 5000 briefly references fire pumps, requiring that the fire pumps in high-rise buildings be fed from the emergency system and monitored from the emergency command center. To reserve space for electrical equipment and fire pump controllers, coordinating early with the architect is critical. There are some battles you have to continually fight, and you will have better luck the earlier you start.

The fire protection engineer will review the existing water pressure and determine, if required, what type and size the pump will be. He or she will review and design to NFPA 20, NFPA 1: Fire Code, NFPA 72: Fire Alarm and Signaling Code, and any other specifications, local codes, or amendments to the codes. NFPA 1 Section 13.4 lists requirements for fire pumps. These are primarily taken from NFPA 20 and relate to the design of the fire pumps. NFPA 1does not deal specifically with power to fire pumps. NFPA 72 lists monitoring requirements for fire pumps by the fire alarm system.

Power sources

NEC Article 695 starts appropriately with the requirements for the power source for electric motor. Where the power source is determined to be reliable, only one source of power is required. NFPA 20 Annex A gives clear direction as to what is determined reliable. The source cannot have had more than a 4-hr shutdown in the previous year. So, if the project is a new building, the local utility will need to be contacted to determine what outages occurred in the past year. Also, the service connection cannot be from an overhead service. Finally, more than one disconnect cannot be installed on the service conductor.

A single reliable source of power can be furnished by one of three methods:

- A dedicated service from the utility, or a tap ahead of the normal utility service disconnecting means.

- An “on-site power production facility.” This is a facility that is continuously running. A standby generator does not meet this requirement.

- A dedicated feeder from a dedicated utility service. It should also be noted that phase converters are not permitted. Phase converters convert a single-phase service into a 3-phase service, but due to the voltage imbalance they cause, they can have a negative impact on the fire pump controller.

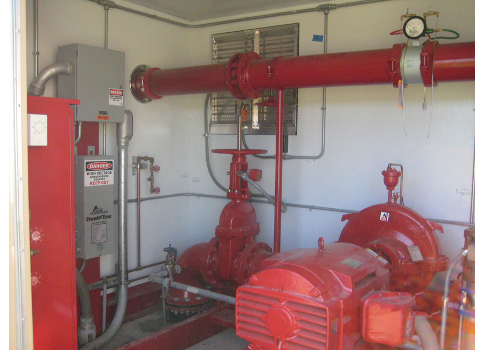

In practice, the most commonly used single source for a fire pump is the tap off the electrical service. To meet NEC requirements, this has to be ahead of the main electric service; has to be in a different cabinet, enclosure, or vertical switchboard/switchgear section from the service; and is required to minimize the possibility of damage from fire. It’s a good idea to locate the tap enclosure in a different area or even a separate room from the main electrical service equipment, so that a fire at the main electrical equipment will not affect the fire pump service.

Where a single source of power does not meet the reliability requirements, a second alternate source of power must be provided. The alternate source of power may be a combination of the single source options. The alternate source may also be a standby generator. Finally, a diesel or steam-driven backup fire pump is allowed to substitute for an alternate electric source.

Both the NEC (695.3(C)) and NFPA 20 (9.2.2(4)) recognize that multibuilding campus-style arrangements have unique requirements. Many larger industrial facilities, military facilities, and institutional facilities purchase their power at a substation at high- or medium-voltage and then the owner is responsible to distribute power within the campus to the buildings. Providing a dedicated service or a dedicated feeder to the fire pumps is just not feasible. The codes address these common situations by requiring two electric feeds that originate from independent sources. Note that a loop feed to a building with both legs originating from the same substation does not meet this requirement, and an alternate source of power, such as a standby generator, would be required. This part of the codes is subject to various interpretations, and the prudent engineer will seek the authority having jurisdiction’s (AHJ) interpretation upfront.

Having laid down the requirements concerning the source of power, Article 695.4 gives requirements for the continuity of power. The main goal is to maintain power to the pump(s); however, at first glance many of these requirements will feel wrong because they are opposite of how the rest of the code is written. We need to take a step back to think about this. Most of the NEC is written to minimize the risks of fires, and therefore equipment is taken offline when it is in danger of starting a fire. However, here the codes are addressing situations where the fire has already started. Therefore, the equipment must continuously run to protect lives, regardless of the risk to the equipment or additional fires. Keeping this reasoning in mind will help clarify the codes’ intention.

To keep the power available to the motor, minimizing the number of ways to disconnect the circuit is important. Although a direct connection is preferable, the NEC allows one disconnecting means, with overcurrent protection, between the source and fire pump controller or transfer switch. When a standby generator is used as an alternate supply, an additional disconnect, and overcurrent protection, is allowed. The NEC also recognizes that a multibuilding campus-style arrangement is more complex and will require additional disconnecting means, and for only this situation, it does not give a limit to the number of disconnects.

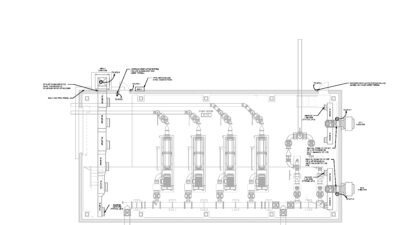

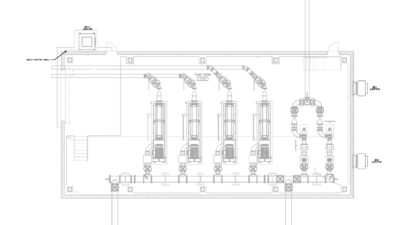

The overcurrent protection requirements (NEC 695.4(B)(2) and (NFPA 20:9.2.3) are important, because the protection will be set to act as though there were a direct wired connection. The only protection allowed is to trip during a short circuit fault. To do this, the overcurrent protection device (OCPD) must be rated for the locked rotor current (LRC) of the largest motor and the jockey pump, and then the sum of the remaining pumps and associated accessory equipment (see Figure 1). New to the codes, when a “listed” fire pump OCPD is used, protection is allowed and specific trip settings are listed in 695.4(B)(2)(b) and 20:9.2.3.4.1.

Example 1

In Example 1, we review sizing an overcurrent protective device (Figure 1). At 460 V, the full-load amps (FLA) for the 50 hp motor is 65 amps, but the locked rotor current (LRC) is 363 amps per NEC Table 430.251(B) or NFPA 20 Table 9.5.1.1. We also have a 2-hp jockey pump. Although the FLA is 3.4 amps, the LRC for the jockey pump is 25 amps. Adding the two LRCs together, we have 388 amps. Per NEC 240.6 the next size standard overcurrent protective device (OCPD) is 400 amps.

When a standby generator is used, the OCPD is sized to allow for instantaneous pickup of the full pump room load only, not the LRC. The OCPD is not required to provide any overload protection, only short-circuit protection (see Example 2). Although not required, ground fault detection (not protection) is allowed by code. Providing a local visible signal and a tie to the BAS and/or to the fire alarm system should be considered for maintenance purposes. When connecting to the fire alarm system, NFPA 72:23.8.5.9 requires that any signal other than a “pump running” signal be supervisory. NFPA 20:10.4.7 requires four signals to be transmitted remote from the pump when the pump room is not constantly attended. They are “pump running,” “loss of phase power,” “phase reversal,” and “alternate source of power connected.” Only the “pump running” signal can be either an alarm or supervisory signal.

Example 2

Let’s look at Figure 1 again and size the OCPD for a standby generator. The FLA for the two motors is 68.4 amps. Per NEC Table 430.52 the maximum rating for the inverse time breaker OCPD is 250%; therefore, the maximum OCPD is 171 amps. The next standard size OCPD is 175 amps. An acceptable range would be 150% to 250%. Therefore, using 175%, the OCPD should be rated for 125 amps.

The disconnecting means for the fire pump system must be clearly identified, be separate from the other disconnects in the facility, be lockable in the closed position, and be monitored in the closed position. All of these requirements are designed to keep the fire pumps online, and prevent mistakenly shutting the fire pump down. Imagine the beginning of the firefighting effort when in the rush to cut power to the building, the fire pump disconnect is mistakenly opened by the very team that is trying to fight the fire. These regulations are in place to eliminate this potential scenario.

Transformers are only allowed when the service voltage is different from the fire pump requirements. If a transformer is required, it must be dedicated only to the fire pump system. It must be sized for 125% of the fire pump motors and jockey pump, and 100% of the remaining loads.

See Example 3 to size a transformer. The transformer can only have primary side overcurrent protection. The overcurrent protection complies with the earlier requirements in that it is intended only for short-circuit fault protection, and is set for the LRC of the largest motor and jockey motor and the FLA of the remaining loads.

Example 3

Using the pumps from Examples 1 and 2, let’s size a transformer to feed the fire pump. This time the service is 4160 V. A dedicated 4160 V to 480/277 V transformer will be used to supply voltage to the fire pump system. What size should the transformer be? Using the information from Example 1, we can calculate the sum of the FLA and multiply by 125%.

The next standard transformer size is 75 kVA.

Next let’s look at what size overcurrent protective device is allowed, but remember only on the primary side. From Example 1 we know that the sum of the LRC is 388 amps. This needs to be converted to the primary side of the transformer.

The next standard size overcurrent protection device for the primary side is 50 amps.

The code recognizes in 695.5(C) that a multibuilding campus-style arrangement with feeders and distribution radials/loops will require the distribution transformers to feed additional loads. For these situations, distribution transformers are allowed. The transformer is still required to be sized for 125% of the fire pump motors and jockey pump, and 100% of the remaining loads, including the non-fire pump loads. The overcurrent devices may be set as normally required by the code (NEC Table 450.3(A) and Table 450.3(B)), and must be set for indefinite time for LRC of all of the fire pump motors, LRC of the jockey pump, FLA of the associated fire pump accessory equipment, and 100% of the remaining loads.

Conductor protection

The conductors feeding the fire pump system from a utility or on-site power production facility must be protected from a building fire as well. They must be installed outside the building until they enter the fire pump room. When they are installed indoors, the cables are still permitted within the building when they meet NEC section 230.6, which usually means they are routed under the building or encased in 2 in. of brick or concrete. From the load side of the last disconnect, the route of the fire pump supply conductor must be independent of other wiring and protected from damage. As this is relevant only to cables outside of the fire pump room, it typically applies only to the conductors run from the standby generator. When run through the building, the conductors must:

- Be encased in a minimum of 2 in. of concrete, or

- Be protected by a dedicated fire rated assembly, listed to achieve a minimum fire resistance rating of 2 hrs, or

- Have a 2-hr fire rating by using a listed electrical circuit protective system.

The conductors directly feeding the fire pump from the controller, including the control wiring, must be installed in rigid metal conduit, intermediate metal conduit, electrical metallic tubing, liquid-tight flexible metal, liquid-tight flexible nonmetallic conduit Type LFNC-B, listed Type MC cable with an impervious covering, or Type MI cable. New to the 2014 NEC is a requirement that a listed type of termination for the cable be used. Twist-on and soldered wire connectors are no longer permitted.

While the overcurrent protection to the fire pumps is sized indefinitely at LRC, the conductors feeding the fire pump are required to be sized at a minimum for 125% of the fire pump motors and the jockey pump plus 100% of the associated fire pump equipment. Of course this is the minimum, as the impedance in the cables due to long runs must also be considered. The voltage drop at the incoming (line) terminals to the fire pump controller has to be less than 15% during starting conditions. The voltage drop during running conditions at the outgoing (load) terminals of the controller has to be less than 5%, and this is required to be calculated at 115% of the FLA. This is a change from the 2011 code, which required the voltage drop to be calculated at the motor terminals.

Example 4

You may have noticed that the conductor size for the fire pump system feeder of previous examples has not been calculated yet. So let’s determine the conductor sizes required to feed the fire pump system. We’ll assume that equipment terminals are 75 C and the distance from the transformer to the controller is 200 ft. First, we must determine the minimum cable ampacity. If you remember, the ampacity is based on the FLA, not the LRC. We’ve already calculated this value in Example 3. The sum of FLA x 125% was 85.5 amps. So, from NEC Table 310.15(B)(16), a THWN #3 AWG copper cable is sufficient, until we look at voltage drop.

For the voltage drop, the NEC requires two calculations: one requiring a max drop of 15% during motor starting conditions, and another during running conditions requiring 5% at 115% of FLA. The basic voltage drop equation is below. (This neglects inductance).

For motor starting conditions, the current was calculated in Example 1 as 388 amps.

Per NEC Chapter 9, Table 8, a #3 AWG cable is 56,620 Cmils and is sufficient.

The second calculation is for 5% max voltage drop at 115% FLA.

Again, a #3 AWG cable is sufficient. Therefore, a #3 AWG conductor will be used to supply the fire pump system.

Finally, what size ground conductor is required? This is based on the upstream OCPD, equivalent to 400 amps, requiring a #3 AWG copper conductor per NEC Table 250.122.

These examples have provided some insight into the basic design process of providing power to fire pumps. As we’ve seen, NEC 695 and NFPA 20 are critical to understanding the concepts behind providing power to fire pumps. Be sure to determine up front what the local jurisdictional requirements are, review your design in accordance with the standards, and then coordinate your design with the local AHJ. The uniqueness of designing power for fire pumps will be challenging at first. Keep in mind that when your design is operating, you will be providing life-sustaining protection to victims of fire as well as those men and women risking their lives to stop the fire and rescue the victims.

Ernest E. Leaf is a senior electrical engineer at Stanley Consultants. He has 18 years of experience designing electrical power distribution systems for universities and airports, including numerous fire pump motor installations.