COVID-19 affected engineers and building professionals’ designs in many ways, including HVAC and plumbing

Participants:

- Matt Goss, PE, PMP, CEM, CEA, CDSM, LEEP AP, Senior Vice President – MEP/Energy Practice Leader, CDM Smith, Latham, N.Y.

- Richard Heim, PE, LEED AP, Project Manager, RMF Engineering, Baltimore

- Sean Lawler, PE, LEED AP, Principal, Project Manager, Affiliated Engineers Inc., Seattle

- RA McNutt, PE, Mechanical Engineer, Lockwood Andrews & Newnam Inc. (LAN) Dallas

- Kevin Miller, PE, LEED AP, Principal, Certus Consulting Engineers, Carrollton, Texas

What unique HVAC systems or products have you specified to help mitigate COVID-19 impacts?

Matt Goss: We are being asked to provide increased amounts of outside air, additional/increased filtration media and other devices such as plasma/ionization and UV.

What indoor air quality or indoor environmental quality needs have you worked toward on a recent project, as it relates to COVID-19?

Matt Goss: We have worked toward incorporating additional filtration and mitigation measures on recent projects in both design and construction.

Sean Lawler: Increasing outdoor air fractions or providing once through air in the HVAC system has been a common design solution discussed over the past year. However, considerations for adequate heating or cooling capacity must be factored. Additionally, higher levels of filtration have been discussed such as increasing the minimum efficiency reporting value (MERV) rating where feasible with the available fan power. Depending on the geographic location and occupancy type of a building, the minimum MERV rating required by applicable codes and standards may only be MERV 7. ASHRAE’s epidemic task force core recommendation in response to COVID-19 is to use MERV 13 filtration or better to reduce airborne infectious aerosol exposure.

RA McNutt: For a recent project, the client asked that we add MERV 13 filters and a UV light system keeping in mind COVID-19 and future COVID-type issues. We elected to use a Trane’s Catalytic Air Cleaning System that uses UV plus photocatalytic oxidation. It is a little more aggressive than just the UV light by itself.

What unusual or infrequently specified products or systems did you use to meet challenging HVAC needs?

RA McNutt: A college art room needed an exhaust system to remove objectionable odors and chemicals while creating projects. We selected a total energy wheel to go with a fan coil unit to provide cool and warm air (for the occupants) while they were creating and exhausting the fumes outside. We specified a small chilled-water Aaon unit that had the total energy wheel, coils and fan all in one small cabinet. The best part was we got our exhaust fan and supply fan all built into the single air handling unit, saving on space. Additionally, over half the energy normally needed for this type of unit was saved due to the total energy wheel.

How have you worked with HVAC system or equipment design to ensure a building’s energy efficiency requirements are still met while achieving COVID-19 mitigation strategies?

Matt Goss: Yes, even though we are addressing COVID-19, energy performance standards are important and must be met/exceeded

Richard Heim: This is certainly a challenge. They often oppose each other, so it becomes a balancing act of finding the right level of COVID-19 mitigation while minimizing the impact on the energy efficiency of the building. How the owner/client provides multiple options with the varying impacts allows them to prioritize what is most important and make an informed decision on the best path forward.

Sean Lawler: One recommendation for energy efficiency with increases in outdoor air fractions is to use more heat recovery. Various heat recovery options are available including run-around loops, wheels and cross-flow plates. The use of heat recovery chillers also allows for heat recovery from coincidental heating and cooling demands within the building and can be used for pulling heat out of the exhaust air and preheating supply air and terminal reheat.

Kevin Miller: In dealing with the pandemic, energy efficiency of existing hospitals took a back seat. Hospitals were doing everything they could to keep patients and staff as safe as possible and operational costs to do so were not a priority. However, as engineers, we cannot completely ignore energy efficiency and should look for creative ways to minimize additional energy required while focusing on the primary objective.

In one rural hospital, the desire was to convert four existing patient rooms to be negative pressure for use as pandemic rooms. The hospital was served by multiple small DX RTUs with MERV 14 filters. To directly exhaust these four rooms would require additional outside air to be introduced to maintain positive building pressure. In some outside air conditions, the existing equipment would not have the ability to sufficiently dehumidify the additional outside air, creating issues of high humidity in the building. Additional treatment of the outside air would result in both an initial capital expenditure and higher energy costs.

Working with the hospital governing body, infection prevention and the authorities having jurisdiction, it was agreed that the rooms could be made negative relative to other areas by returning those rooms through HEPA filters. The return grilles were removed and HEPA fan filter units installed with dedicated ducts back to the RTU. This solution allowed the rooms to be made negative with return HEPA filtered, but without affecting the overall air balance of the system. The adjacent areas all became slightly more positive, but still proportioned.

The solution was installed at minimal first cost and minimal disruption to the existing facility and also with negligible additional energy consumption.

What recommendations do you have for manufacturers as they design and market products intended to address COVID-19 issues?

Matt Goss: Independent laboratory testing and certification.

Richard Heim: Simplicity and ease of maintenance is very important. If a product is overly complicated and/or has integration with multiple devices, this can interfere with its actual effectiveness if a device is out of calibration or fails. If it is not easy to be maintained, it is also that much more likely to be ignored or forgotten.

Sean Lawler: Buildings are designed to have a life expectancy of 30, 40, 50 or more years — so systems implemented to address today’s needs should also consider future needs. Products and systems should have resiliency and adaptability at the forefront of design and development to support the needs and requirements of the future. An example may be using filtration that is effective for viruses and for seasonal wildfires.

RA McNutt: I would recommend that on every unit with a chilled water coil that unit should be wired for the installation of UV lights downstream of the coil. In March 2020, a contractor told me about a building owner who requested an estimate to install UV lights in all 10 of his air handlers. The contractor priced it and found that the electrical costs were more than the actual UV lights and fixtures and it was frustrating to him as the total power draw of the UV lights in each unit was so small. He wished that the manufacturer had at least installed the wiring in the unit at the factory set up for UV bulbs as it would have been minimal cost to them and the owner if there was a surprise need for UV lights later.

Kevin Miller: Equipment manufacturers are key partners in our industry. Building owners, operators and engineers necessarily rely on manufacturers to bring emerging technologies forward and help in the evaluation for use in specific applications. As an integral part of the team, we count on manufacturers to share objective information. A particular product or technology obviously will not fit every application. The manufacturers and vendors that are long-standing partners and will continue to be a go-to resource are those that objectively share their knowledge and openly acknowledge and advise when a particular application is not integral the right fit or when other system modifications should be considered for it to be effective.

What best practices should be followed to ensure an efficient HVAC system is designed?

Matt Goss: Energy modeling and commissioning.

Richard Heim: Early coordination and understanding with all members of the design team is important. Having a favorable system layout allows a system to operate more efficiently, which often requires more space for the equipment and the distribution. Implementing proper automated controls is also important as systems have varying components and energy savings devices. If used improperly, this could actually lead to an increase in energy usage.

Sean Lawler: Efficient HVAC systems start using proven fundamentals such as good duct design for lower fan energy and lower heating hot water temperatures. Decoupled ventilation systems from the heating and cooling systems, such as radiant ceilings with dedicated outdoor air systems, have energy efficiency benefits as well as allowing for high outdoor air fractions to reduce recirculated air.

RA McNutt: One of the best practices is designing air handling units for large and long filters to reduce system pressure drop. The world of HVAC is heading toward higher-efficiency filters. I would recommend designing air handling systems to accommodate large filter sections with lots of length (about 3 feet). Owners do not have to always use high efficiency filters, but they have the option to put them in if they want to save on energy by lowering filter pressure drop on MERV 13 filters.

What are some of the challenges or issues when designing for water use?

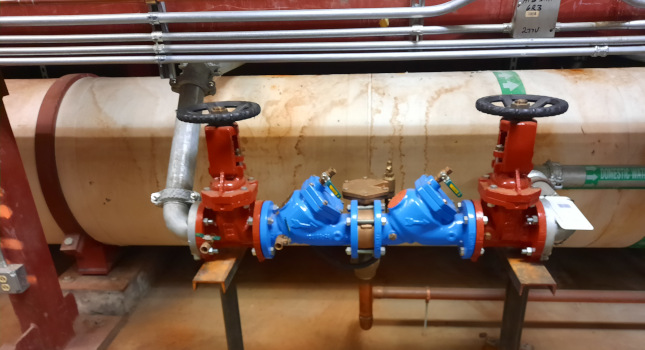

Richard Heim: The main challenge with water use has been proper cross contamination prevention. Ensuring the water system is safe from cross contamination through the use of proper backflow devices is important to maintain safety of the water system.

Sean Lawler: Legionella prevention in domestic water systems is vitally important and can be achieved through a few means including heat, copper silver ionization and filtration systems. Control of legionella once a colony forms can be difficult, so it is important to work through solutions with owners early in design to help prevent the issue from occurring. In regards to COVID-19, considerations for sanitizing and flushing should be made before reoccupancy for buildings unoccupied during the pandemic or buildings with parts of domestic water systems stagnant over the past year.

Describe a facility in which there were specialty air movement requirements, such as unique air pressure needs or high-velocity low-speed fans.

Sean Lawler: Health care institution’s specific requirements for air-change rates and pressure requirements are governed by FGI/ASHRAE 170 and similar health care guidelines. Specific airborne isolation rooms are designed for use by patients with highly infectious diseases. These isolation rooms are negative pressure with active monitoring, provided separate exhaust systems and discharge with stacks.