Universities cover a wide range of building types, requiring different HVAC design across campuses.

learning objectives:

- Understand how different building types on college campuses impact system design goals and considerations.

- Learn how refrigerant changes, along with other sustainability initiatives, are impacting HVAC design for university buildings.

HVAC insights:

- A priority for existing college and university buildings is cost-effective indoor air quality upgrades that enhance health without major infrastructure changes.

- Specialized university spaces require tailored HVAC, refrigeration and plumbing designs to meet unique functional and comfort needs.

Respondents:

- Dennis Coblentz, Project Manager, RMF Engineering, Charleston, SC

- Cindy Cogil, PE, FASHRAE, Vice President, SmithGroup, Chicago, IL

- Abdullah Khaliqi, PE, MCPPO, CPQ, Principal, Academic, Fitzemeyer & Tocci Associates, Inc., Woburn, MA

What unique heating or cooling systems have you specified into such projects? Describe a difficult climate in which you designed an HVAC system for a college or university project.

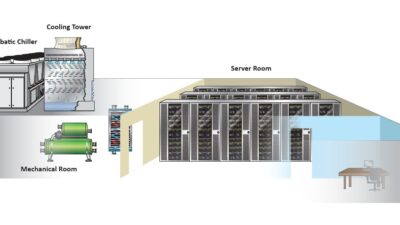

Cindy Cogil: We designed a hybrid, multi-source heat pump system for a new 300,000 square foot, fully electric academic building in a new mixed-use development. The system will connect to a nearby pump transfer station and utilize wastewater as a heat source and sink. It is built to initially operate independently from sewer thermal, but once the development is sufficiently built out and wastewater flow reaches a minimum threshold, a plant addition will be constructed to house the prescreening equipment and heat exchangers, enabling integration with the building’s heat recovery chiller modules.

How have refrigerant regulation changes altered design or specifications of HVAC systems?

Abdullah Khaliqi: Refrigerant regulation changes have significantly impacted HVAC system design and specifications. With stricter limits on global warming potential (GWP) and phase-outs of hydrofluorocarbons refrigerants under policies like the Environmental Protection Agency’s SNAP program, engineers are shifting to low-GWP refrigerants such as R-32, R-454B or natural refrigerants like carbon dioxide and ammonia. This affects equipment selection, system design and safety considerations, due to differences in flammability and pressure. Additionally, manufacturers are innovating with compressors and improved leak detection. Designers must stay current with evolving regulations to ensure compliance, optimize energy performance and minimize environmental impact.

For existing buildings, what HVAC, outdoor air, UV-C, bipolar ionization or other indoor air quality strategies are you designing?

Cindy Cogil: As part of a partial building renovation, we incorporated an air scrubbing unit that employs a non-toxic sorbent-based air cleaning technology to reduce the new air handling unit’s (AHU’s) outside airflow to be below the value that would require energy recovery, in accordance with ASHRAE Standard 62.1: Ventilation for Acceptable Indoor Air Quality. The AHU was located on the lower level of the building, where there was neither sufficient ceiling height to accommodate a second air tunnel above the unit, nor was there adequate floor area within the mechanical room to accommodate a second air tunnel alongside the unit without enlarging the size of the mechanical room and the expense of the program.

Abdullah Khaliqi: For existing college and university buildings, we’re prioritizing cost effective indoor air quality (IAQ) upgrades that enhance health without major infrastructure changes. Strategies include increasing outdoor air ventilation through demand-controlled ventilation and upgrading to MERV 13+ filters where possible. We’ve also explored retrofits with UV-C lighting in AHUs to reduce microbial growth on coils and drain pans. IAQ sensors integrated with building automation system platforms provide real-time data for continuous optimization.

What unusual or infrequently specified products or systems did you use to meet challenging heating or cooling needs?

Cindy Cogil: A recent project incorporated mass timber construction in the building wing containing active learning classrooms. We designed an underfloor air distribution (UFAD) system to eliminate overhead ductwork and showcase the exposed structure. UFAD supports thermal stratification for improved ventilation effectiveness, carrying away heat and pollutants from the occupied zone. The raised floor plenum enables flexible, modular power and data distribution for easy “plug-and-play” systems to accommodate evolving teaching methods and space uses.

How have you worked with HVAC systems or equipment design to increase a building’s energy efficiency?

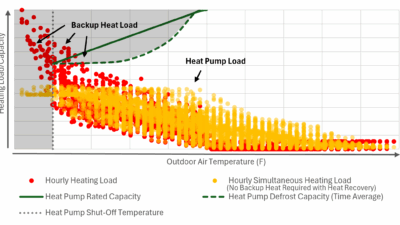

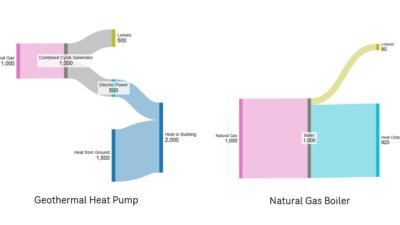

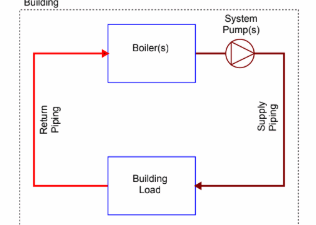

Cindy Cogil: Geo-exchange is gaining momentum in higher education due to the combination of climate action commitments, end-of-life HVAC systems and district thermal energy infrastructure, technological advancements, including more cost-effective drilling techniques and improved heat pump efficiencies, federal and state incentives, and the overall greening of the electrical grid. We’ve employed hybrid geo-exchange systems at the building level with supplemental systems like boilers or cooling towers to handle peak loads. We are also designing larger-scale district energy geo-exchange plants that can more cost-effectively condition a greater number of buildings with diverse typologies and energy demands.

Abdullah Khaliqi: We increase a building’s energy efficiency by selecting right-sized HVAC equipment, integrating variable speed drives and optimizing system controls for part load performance. We often design around heat recovery systems, such as enthalpy wheels or runaround coils, to capture energy from exhaust air. Demand-controlled ventilation based on carbon dioxide or occupancy sensors ensures outdoor air is only supplied when needed. In many university projects, we pair chilled beams or radiant systems with dedicated outdoor air units for efficient latent and sensible load management. Early energy modeling and coordination with controls vendors ensure the HVAC design aligns with performance goals and code requirements.

What best practices should be followed to ensure an efficient HVAC system is designed for this kind of building?

Abdullah Khaliqi: Designing an efficient HVAC system for college and university buildings requires a combination of best practices across planning, design and implementation. Key strategies include starting with comprehensive energy modeling to guide system selection and capacity planning. Other strategies include using zoning and variable speed technologies to match loads and reduce energy waste, or incorporating heat recovery, demand-controlled ventilation and smart controls to optimize performance. Early coordination with the architect supports passive design strategies and equipment access. Specifying systems that meet or exceed ASHRAE 90.1 and local energy codes, and engaging in commissioning and owner training, ensures long-term efficiency.

Have any institutions indicated they plan to use Healthy Green Schools & Colleges (HGSC) as a standard in the future?

Abdullah Khaliqi: Yes, we’ve seen growing interest from institutions in aligning with the HGSC standard, particularly those pursuing broader sustainability or wellness goals. While it’s not yet as widely adopted as LEED or WELL, several universities have indicated plans to use HGSC as a framework for facility upgrades, especially for improving IAQ, cleaning practices and HVAC maintenance in existing buildings. Focusing on practical, operations-based improvements appeals to facilities teams. We’ve begun incorporating HGSC-aligned strategies, like enhanced filtration (MERV 13+), IAQ monitoring and ventilation verification into design specs to support future compliance and healthier learning environments.

How does HVAC, refrigeration or plumbing engineering address the needs of specialized spaces, such as auditoriums, libraries, laboratories and sports facilities in university buildings?

Abdullah Khaliqi: Specialized university spaces require tailored HVAC, refrigeration and plumbing designs to meet unique functional and comfort needs. Auditoriums demand quiet systems with precise airflow and displacement ventilation to maintain comfort without noise disruption. Libraries require consistent temperature and humidity control to protect books and archives, often using zoned systems and humidification. Laboratories involve high ventilation rates, fume hood integration and dedicated exhaust systems with energy recovery. For sports facilities, we address high occupancy, moisture and odor control through robust ventilation, dehumidification and separate plumbing systems for locker rooms. Each space requires custom load calculations, airflow modeling and controls integration.