Specialty facilities like sports stadiums and theaters have to do more than host the entertainment these days—they’re full of technological bells and whistles and high client expectations when it comes to HVAC systems.

Respondents

- Edward Clements, PE, LEED AP BD+C, Vice President-Mechanical Engineering, HGA Architects and Engineers, Alexandria, Va.

- David Conrad, PE, Vice President, Peter Basso Associates Inc., Troy, Mich.

- George B. Holzbach III, PE, Associate Director of Mechanical Engineering, Setty & Associates, Fairfax, Va.

- Kevin Lewis, PE, LEED AP BD+C, Senior Vice President, Venue Practice Director Henderson Engineers Inc., Overland Park, Kan.

- Michael Rogers, PE, LEED AP, Senior Principal, Smith Seckman Reid Inc., Nashville, Tenn.

- Michael Troyer, PMP, RCDD, CTS, LEED AP, Principal/Senior Technologies Designer Interface Engineering, Portland, Ore.

- Corey Wallace, PE, SET, Principal Engineer, Southland Industries, Las Vegas

CSE: What unique heating and cooling systems have you specified into such projects? Describe a difficult climate in which you designed an HVAC system.

Clements: For theater buildings, within the performance space, we tend to use displacement ventilation systems more often than not. They provide the perfect balance of occupant comfort and low noise while also taking advantage of building cavities that exist within the structure for distribution, thereby eliminating a significant amount of low-velocity ductwork. Each climate zone brings its own challenges, but we have designed many halls in Northern Tier states where freeze protection and cold-weather conditions are a significant factor in the design. For example, variable frequency drives mounted outdoors-even when inside appropriate enclosures-will need to be heated to prevent drive failure below -25°F. Normally, the concern with outdoor drives is keeping them cool. This is not necessarily the only factor for the Northern Tier.

Rogers: NHL facilities have stringent requirements that can be difficult to maintain in some areas of North America. With professional hockey moving to all areas of the United States, (Las Vegas, Tennessee, Florida, etc.), it is difficult to maintain the proper indoor-air environment needed to ensure "good ice" conditions and fan comfort. The NHL requires 60°F at 35% RH (32 grains/lb) pregame and 65°F at 45% postgame condition. In hot, humid locations, these guidelines require special treatment by way of desiccant dehumidification, or specialized low-temperature conventional refrigeration. Energy consumption is a definite concern for systems meeting these goals, and designers should run comparison models to determine the best approach. In Nashville’s Bridgestone Arena, SSR implemented low-temperature chillers as a way to retrofit existing HVAC systems. In Orlando’s Amway Center, although not an NHL facility, they wanted to meet the same criteria. SSR used desiccant dehumidification systems to meet the goals.

Lewis: The unique challenge in large venues is delivering air at the right temperature and at the right place so patron comfort is maximized. For the Sacramento Kings’ new arena in California (the Golden 1 Center), we teamed with AECOM to create a unique delivery system that provided air in the lower bowl through the risers, providing supply air where the patrons are, which created more even temperature distribution, cleaner air, and a better fan experience.

CSE: Describe a difficult climate in which you designed an HVAC system.

Holzbach: In basketball arenas, the wood floors the players play on are required to be kept under very precise humidity requirements. As a result, we employ specialty HVAC equipment and designs to ensure a very tight humidity band in the applicable spaces, including a steam humidifier and a fabric ductwork system that delivers the air.

CSE: What unusual or infrequently specified products or systems did you use to meet challenging HVAC needs?

Clements: Probably the most common thing in theater buildings is the use of custom terminals. Off-the-shelf diffusers are often not quiet enough for use in sound-critical spaces. Instead, we’ve tended to either use custom-built diffuser boxes or baffles or make use of the acoustic reflectors in a space to also provide air diffusion in overhead system areas.

Lewis: We know that the HVAC systems don’t need to be front and center as a design element in these type of facilities, but we also want everyone in the building to be comfortable. We work with manufacturers directly to make sure the products we specify are right for the job, and if not, we’re not afraid to challenge their off-the-shelf project and create something custom that is right for the application.

CSE: What types of air economizers or other strategies are owners and facility managers requesting in specialty facilities?

Holzbach: Airside economizers are required by code in most areas, so typically these systems are employed automatically. Additionally, we use both airside and waterside economizers wherever possible to reduce both the size of the HVAC equipment and the energy consumption of the systems. We also use dedicated outdoor-air systems (DOAS) to deliver "decoupled" ventilation air in an effort to reduce equipment costs and increase energy conservation. Under this scenario, a separate HVAC rooftop air handler delivers the isolated ventilation air to each occupied space of the building. Building exhaust is tied back into this system (toilets, kitchen exhaust, etc), and the energy from this exhaust is then transferred back to building air via an "energy wheel" in the DOAS unit, thus reducing the energy necessary for the DOAS unit. This represents significant energy savings for the building.

Clements: Due to the high occupant counts (and resulting ventilation loads), energy-recovery systems are one of the first things that I typically hear facility operators asking for-anything that they can do to minimize the energy impact of introducing significant amounts of outdoor air. Yes, economizers are used to take advantage of temperate conditions, but mitigating the peaks through energy recovery has been a significant focus.

Conrad: Airside and waterside economizers are being requested.

Lewis: All venue projects have a large number of occupants, so outside-air quantities are going to be large. As long as the climate is such, we strongly recommend the use of air economizers. This strategy does not add a lot of first cost and many times can offer a quick payback.

CSE: What types of air balancing do you typically include in your designs? Describe the project.

Holzbach: Air balancing follows the design of the HVAC system. It’s the system and design that dictates the cubic feet per minute for each space.

Clements: More often than not, acousticians tend not to want balancing devices, which inherently throttle the air by imparting pressure losses, usually as a damper that increases the velocity through the remnant opening in the duct. Balance dampers in or near outlets have a high probability of being singled out as noise sources and are generally to be avoided. We have used CFD modeling to design distribution systems for theater buildings without balancing devices, to understand the likelihood of a successful built solution that achieves air balance without exceeding velocity threshold criteria.

Lewis: The air balancing of a venue is a key component and works hand-in-hand with commissioning a building. With venues having so much volume and associated equipment having the building commissioned on start-up, as well as each year after, we can find a lot of errors and allow for corrections to be made. We strongly encourage each of our clients to make sure they engage in the commissioning process, whether we are doing the work or a third party is hired.

CSE: When working on these types of specialty facilities, describe the HVAC ventilation system, which might include vent hoods, fire-suppression systems, or other specialized ventilation systems.

Rogers: Building pressurization (infiltration control) is a challenge for large-volume, high-roof buildings, such as arenas and indoor stadiums. Balancing all exhaust streams with outside-air (OA) requirements is part of the equation. In a typical arena, we may have 15 cooking hoods, 20 exhaust fans, laundry exhaust, shop hoods, and various other specialized exhaust that have intermittent use. Creating control strategies that take a look at OA requirements, based on occupancy, and balancing this with the exhaust streams that are active is a key part of healthy building-infiltration control. The other piece of the puzzle is stack effect. Stack effect creates buoyancy forces within the bowl area, driving air up and out of the building. Many of the newer facilities do not have tight skins and allow too much air to escape and enter the building unchecked. Having the design and construction team understand the energy implications of a loose building, and work to mitigate this, is important.

CSE: How have you worked with HVAC system or equipment design to increase the building’s energy efficiency?

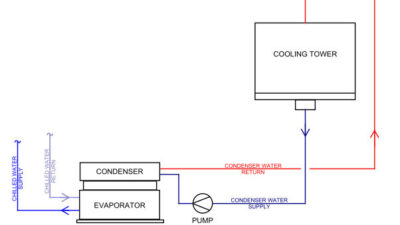

Lewis: When it comes to sustainability, the building’s HVAC system typically offers the most opportunity to save energy and create a system that works in unison to optimize the components. For example, if you have a central plant, you want to make sure the chillers, cooling towers, and pumps are all optimized to deliver the necessary chilled-water volume and temperature, but that they do so in such a way that each component is working as efficiently as possible.

Rogers: We are always looking for ways to capture energy savings. For example, we have used energy-recovery ventilators (ERVs) and low-temperature supply air. ERVs can be used when exhaust streams can efficiently be captured and routed to locations where OA is being introduced. Low-temperature air helps to reduce fan power. Like with any energy-saving strategy, engineers should evaluate each system and compare all aspects, to make sure the system chosen is, in fact, an efficient solution. There are always trade-offs and compromises.