A museum needed an updated HVAC system, including a modular chiller

In this existing museum, most of the HVAC system had surpassed its useful life and required replacement. The original HVAC system design incorporated an airside economizer, which, when paired with the requirement to maintain a minimum of 40% relative humidity (46°F dewpoint temperature) in the building throughout the winter, required extremely large amounts of humidification energy. Note that the 2019 edition of ASHRAE Standard 90.1: Energy Standard for Buildings Except Low-Rise Residential Buildings provides an exception to its economizer requirement when the building is required to be humidified to more than 35°F dewpoint temperature.

The airside economizer mode in the air handling systems is being eliminated in favor of intaking outside air only in the amount required as ventilation air. Chilled water will be required year-round as the airside economizer mode is eliminated.

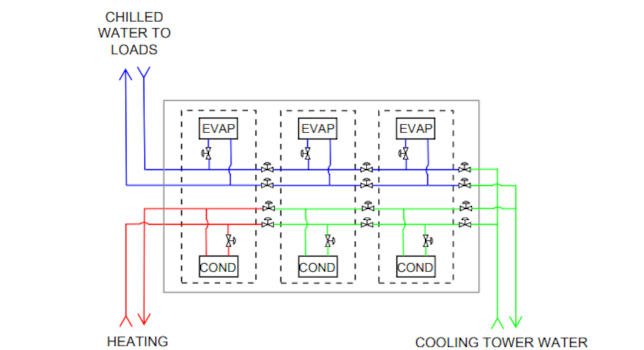

A modular heat recovery chiller that has the capability to simultaneously heat and cool is being provided to replace the existing cooling-only chillers. The modular chiller will be operated year-round. When building heating and cooling loads are balanced, module(s) will operate in heat-recovery mode (see Figure 1). When cooling loads are dominant over heating loads, additional module(s) will simultaneously operate in cooling-only mode (see Figure 2).

Should the museum install a geothermal ground loop in the future in addition to having modules operate in heat recovery mode at times when heating loads are dominant over cooling loads, additional chiller modules could be operated in heating mode to draw heat from the ground loop (see Figure 5).

The modular chiller was chosen because:

-

Each module could automatically switch between heat recovery and cooling modes and allow a varying number of modules to be operated in each mode as dictated by load. This helped to effectively increase the capacity of the chiller in each mode within much less of a footprint than would have been required by separate, dedicated heat recovery and cooling-only chillers. This allowed both modes to be accommodated within the constrained space of the existing mechanical room.

-

Each chiller module can be separately brought into the existing mechanical room, greatly reducing the complexity as compared to bringing larger chillers into the room.

-

Each chiller module has two small, independent refrigerant circuits, which are smaller than the allowance of the local municipality’s refrigeration ordinance.

-

The evaporative cooling tower’s open water loop is being decoupled from a closed condenser water loop, which circulates through the chiller by means of a plate and frame heat exchanger. This would allow the closed condenser water loop to be adapted in the future, if needed, to circulate through a closed-geothermal ground loop. Because the selected modular chiller has internal automatic valves that gives it the capability to send the geothermal loop water to selected evaporators in heating mode (see Figure 5), this would allow chiller modules to draw heat from the earth into the heating hot water, in addition to other modules recovering heat from the chilled water into the heating hot water.

To coordinate with the heating capabilities of the heat recovery chiller, the existing hydronic heating devices in the building, all of which have exceeded their useful life and all of which were originally designed to operate with 180°F heating hot water supply temperature, are being replaced with hydronic heating devices designed to operate with 120°F heating hot water.