ASHRAE 62.1 is best known for its regulation of the amount of ventilation air delivered to each space by HVAC systems through its ventilation rate procedure approach to system design.

Learning objectives

- Know about the basics of designing air ventilation systems.

- Learn about ASHRAE 62.1 and its performance-based goals for HVAC system design.

- Understand the calculations that dictate ventilation system specification.

The building industry is currently moving from prescriptive- to performance-based standards. As energy codes have gotten more stringent, it has forced architects and engineers to find ways for projects to holistically comply based on a design’s overall performance.

The same is happening with ventilation or outdoor air. Many engineers have only designed ventilation systems using the Ventilation Rate Procedure (VRP), but the Indoor Air Quality Procedure (IAQP) has been part of ASHRAE 62.1: Ventilation for Acceptable Indoor Air Quality since it was first published in 1981. There are also third-party certifications, such as WELL Building Standard and the U.S. Green Building Council’s LEED, that require the use of air-quality testing to ensure proper indoor air quality (IAQ) is being achieved for certain credits or optimizations.

It is worth noting that the effectiveness of ventilation systems is predicated on the idea that outdoor air has a lower contaminant level than indoor air. Before either ventilation procedure is detailed, Section 4 of ASHRAE 62.1-2016 requires that the regional and local air quality of the building site be assessed. The air quality should be in compliance with the National Ambient Air Quality Standards (NAAQS), which can be found in Informative Appendix I of ASHRAE 62.1. Any area not in compliance with the NAAQS is considered a nonattainment area.

The U.S. Environmental Protection Agency (EPA) has an online map showing nonattainment zones for particular contaminants. ASHRAE 62.1-2016 Section 6.2.1 details the required air treatment in areas that don’t meet the national standard for particulate matter smaller than 10 micrometers (PM10), particulate matter smaller than 2.5 micrometers (PM2.5), and ozone. In areas that exceed the PM10 threshold, MERV 6 filters must be used at a minimum, and no less than a MERV 11 shall be used if the PM2.5 threshold is exceeded. An air-cleaning device for ozone is also required if the 3-year average annual fourth-highest daily maximum 8-hour average ozone concentration exceeds 0.107 ppm.

Ventilation Rate Procedure

The VRP is the most commonly used of the three procedures included in ASHRAE 62.1. VRP is a prescriptive compliance method that uses the space type, floor area, and number of people to determine the required volume of ventilation air for each ventilation zone. Ventilation zones are not always the same as independent thermal zones, but typically spaces that can be combined into a single thermal zone can also be combined into a single ventilation zone.

ASHRAE 62.1-2016 Section 3 defines a ventilation zone as “any indoor area that requires ventilation and comprises one or more spaces with the same occupancy category (see Table 6.2.2.1), occupant density, zone air-distribution effectiveness (see Section 6.2.2.2), and design-zone primary airflow (see Section 6.2.5.1) per unit area.”

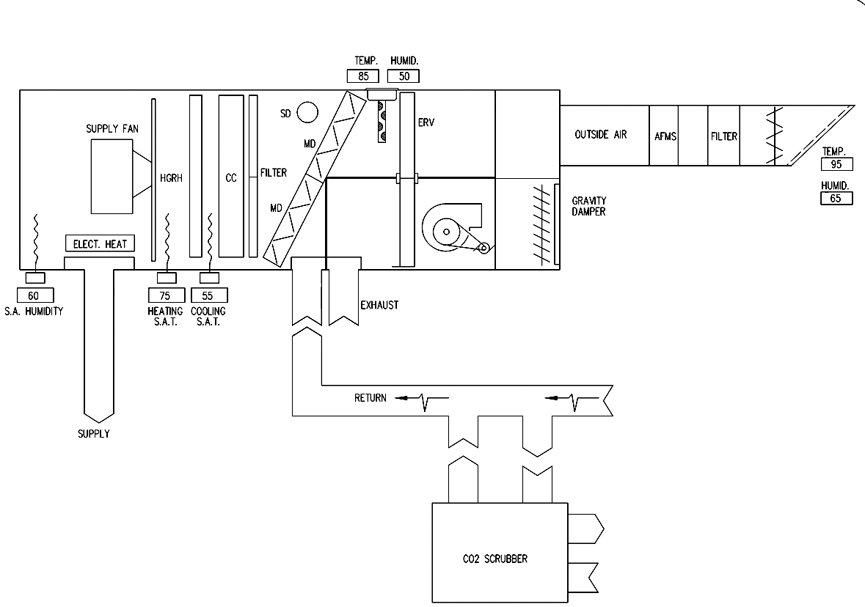

Ensuring every space is properly ventilated by a multizone recirculating system causes them to require the most outdoor air. Single-zone systems and dedicated outdoor-air systems (DOAS) allow better control to deliver exactly the required amount of outdoor air to each zone. In multizone recirculating systems, some spaces are overventilated and others are underventilated.

In climate zones without many economizer hours, conditioning ventilation air is one of the highest loads on the HVAC system, so it’s important to consider the inherent ventilation implications during the system-selection process. Energy models are valuable tools for quantifying the energy-cost differences of ventilation systems. In hot and humid climates, it costs about $2/cfm each year to condition ventilation air and $6/cfm in capital costs for the equipment.

Indoor air quality procedure

The IAQP has become more prevalent in recent years due to more air-cleaning technologies coming to market and the cost to condition outdoor air. IAQP is a performance-based procedure that uses mass-balance equations to calculate the required outdoor-air rate for each zone based on the contaminants of concern. Table E-1 of ASHRAE 62.1 Informative Appendix E describes the mass-balance equations to determine the Vozfor variable air volume and constant-volume systems.

The compelling reason to use the IAQP is it considers the effect of air-cleaning equipment in the calculation of the required ventilation rate. It is possible, when using the IAQP with certain air-cleaning technologies, to design a system with less required outdoor air and maintain equivalent or higher indoor air quality than with the VRP alone. Reduced outdoor air also allows for a reduction in peak heating and cooling equipment capacities and overall energy consumption. A reduction in peak loads can be used to offset the cost of the air-cleaning device.

All air-cleaning technologies are not equal. Some are more effective at cleaning certain contaminants than others. Most air-cleaning technologies don’t have any effect on carbon dioxide (CO2),

which people are constantly producing inside buildings. It is usually controlled by diluting the indoor air with outdoor air containing a lower CO2 concentration.

There is growing concern about the effect of high CO2 levels on the cognitive function of people, based on the results of a study from the Harvard T.H. Chan School of Public Health. The study found a statistically significant link between increased CO2 and TVOC levels and cognitive function. Based on this research, it is important to consider the impact on the CO2 levels when using the IAQP and air-cleaning technology to reduce the required ventilation, or to ensure you are specifying an air-cleaning technology that reduces CO2 as well as other contaminants. This is of particular importance when designing a building type with high occupant densities.

Proper ventilation in buildings is important for maintaining a healthy indoor environment. Buildings with higher IAQ tend to have lower employee absence rates and higher productivity. It’s in the engineer’s hands to deliver a design that balances air quality, energy efficiency, and first cost of equipment for clients by optimizing the required outdoor air using the VRP and/or air-cleaning equipment with the IAQP.