It is essential to balance each system within a building to ensure occupant comfort and efficient equipment operation.

It is essential to balance each system within a building to ensure occupant comfort and efficient equipment operation. This example project involves a water treatment plant in Georgia, a typical operations building with the following space types: electrical room, mechanical room, janitor closet, toilet/shower room, lab, office and a control room/open office.

The electrical room does not have any additional outdoor air or exhaust requirements from ASHRAE 62.1. Referencing the International Energy Conservation Code Section C403: Building mechanical systems, the system was required to have an economizer, which brings in outdoor air to blend with the indoor return air if the outdoor air is at an acceptable temperature and humidity. The overall cubic feet per minute (CFM) for the system also considers any potential infiltration from doors being opened to maintain an overall positively pressurized space.

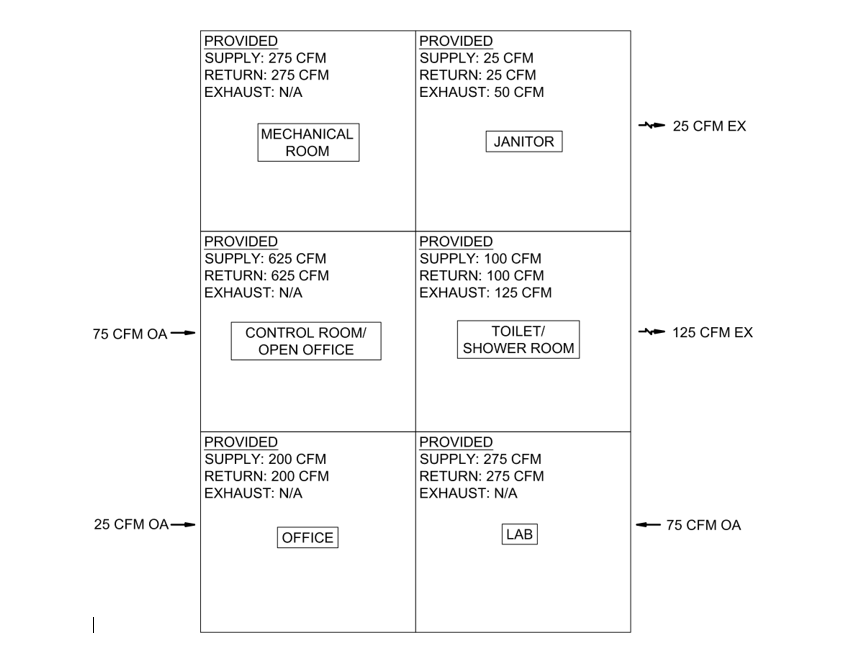

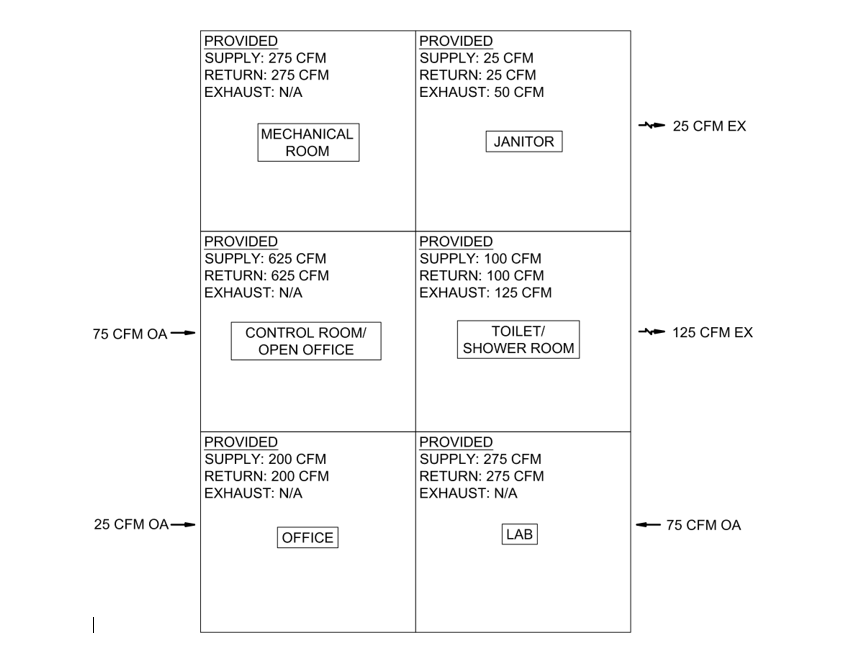

The minimum ventilation requirements for the rest of the spaces were determined using Chapter 5 of ASHRAE 62.1. The lab, office and control room/open office have outdoor air requirements, while the janitor closet and the toilet/shower room have exhaust requirements. For the outdoor air requirements, it was assumed that the lab and office would have an occupancy of two people, while the control room/open office would have an occupancy of four people. The exhaust requirements in the design entailed an exhaust fan tied to an occupancy switch, so the higher values from Table 1 for the associated spaces were selected. The minimum required outdoor air or exhaust air for each space is represented by arrows either directed toward the space (outdoor air) or away from the space (exhaust air). These were rounded up to increments of 25 CFM from the ASHRAE 62.1 requirement.

Next, the overall outdoor air to exhaust requirements were evaluated to assess whether additional outdoor air should be brought into the system. The total outside air requirement for the system was 175 CFM, while the total exhaust air requirement for the system was 150 CFM. Therefore, it was determined that no additional outdoor air was necessary.

The last step was to evaluate each space to ensure it was pressurized as intended. As shown in Figure 1, the minimum required exhaust for the janitor’s closet is 25 CFM, while the supply air necessary to cool the space is also 25 CFM. To help keep this space negative, the exhaust fan was upsized to be 50 CFM. The toilet/shower room is accurately represented as a negative space with 100 CFM supply and 125 CFM exhaust. The other spaces are depicted as neutral, per Table 2.

Regarding the complete system, the overall outdoor air requirement is 175 CFM, while the exhaust requirement is 175 CFM. The goal was to maintain an overall positively pressurized building to combat any potential infiltration, so an additional 25 CFM of outdoor air was provided. The results were 1,500 CFM supply for space conditioning, 200 CFM outdoor air and 175 CFM exhaust.