To prevent the buildup of contaminants and to support overall system efficiency, air quality requires controlled airflow, calculated pressure relationships and conducive outdoor air.

Learning objectives:

- Use ASHRAE 62.1 to calculate ventilation and exhaust requirements for different space classifications.

- Understand the pressurization classifications for positive, neutral and negative spaces.

- Balance supply, return, exhaust and outdoor air for a whole building system.

ASHRAE 62.1 insights:

- Specific space types like labs or wastewater treatment plants use pressurization to ensure balanced air flow.

- Applying ASHRAE 62.1 helps optimize ventilation strategies for high-exposure areas.

Maintaining healthy indoor air quality (IAQ) relies on effective ventilation. ASHRAE Standard 62.1: Ventilation for Acceptable Indoor Air Quality provides guidelines for calculating the appropriate outdoor air and exhaust rates for different space classifications. Applying this standard makes it easier to optimize ventilation strategies, whether for low-occupancy spaces, odor control situations or other high-exposure areas. This optimization ensures proper air exchange while minimizing energy waste. Additionally, it not only ensures regulatory compliance but also creates a safer, more comfortable environment for occupants.

ASHRAE 62.1 Section 6 outlines the procedures for determining the ventilation and exhaust rates needed for different space types within a building and provides guidance about the minimum ventilation rates required to ensure quality air for occupants. For some spaces, such as restrooms and shower rooms, two values are given for required exhaust rates—the lower value applies to continuous exhaust, while the higher value applies to intermittent exhaust. ASHRAE 62.1 ventilation and exhaust tables list occupant densities to consider for each space type to thereby ensure the maximum potential occupants are factored into the system design for each space. If the expected number of people to occupy a space is undercalculated, then the ventilation would not be acceptable based on the space’s outdoor air requirement per person. These values should be used in conjunction with building and space occupancy requirements from the architect involved with the design process.

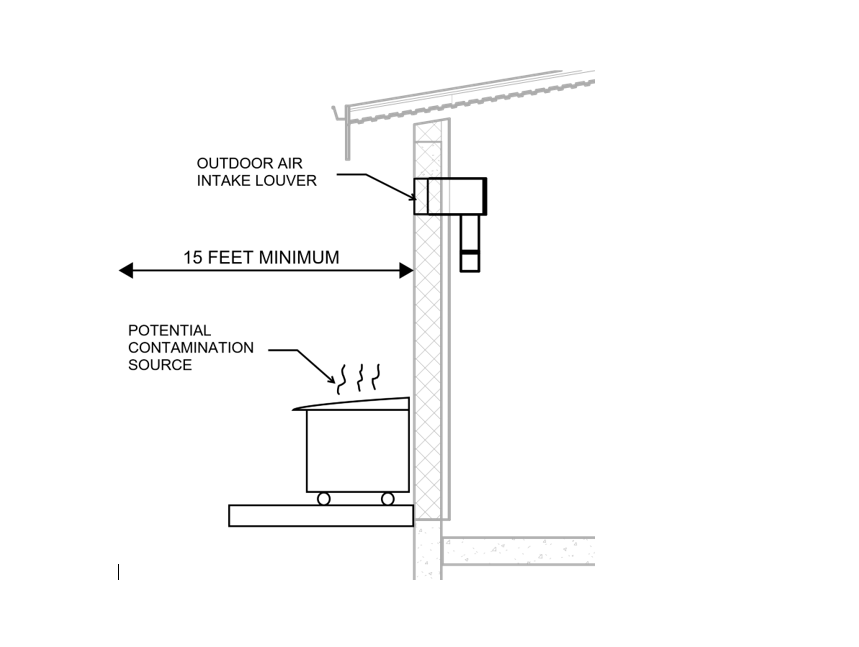

In addition to ventilation rates, ASHRAE 62.1 also states that outdoor air intakes must be installed according to specific separation distances from potential sources of contamination, thereby ensuring the air that people breathe inside a building or space is acceptable. Chapter 5 of ASHRAE 62.1 specifies minimum separation distances from exhaust vents, plumbing sanitary vents, driveways, dumpsters and any other areas that may have the potential for hazardous or polluted air. These separations meet jurisdictional compliance and protect occupant health and safety. As shown in Figure 1, the intake air louver is placed too close to a dumpster, which has the potential to bring odors and fumes into the system. For this specific example, the louver should be placed a minimum of 15 feet from a dumpster.

Another important component to providing quality air to occupants is selecting the correct efficiency filters for potential/existing particulates. ASHRAE Standard 52.2: Method of Testing General Ventilation Air-Cleaning Devices for Removal Efficiency by Particle Size rates air filters using a minimum efficiency reporting value (MERV). The higher the MERV rating, the smaller the particles that can be filtered out of the air. ASHRAE Standard 52.2 also tabulates the minimum MERV ratings for various space types. For example, lower MERV values are used for residential spaces, mid-level ratings are used for commercial buildings, and the highest ratings are used for hospitals. Ratings higher than recommended can be implemented when airborne contagions or allergens are a concern for occupants.

A complementary and specific factor to consider is the placement and design of air diffusers and returns within a space. Even with adequate ventilation rates, poor diffuser placement can lead to uneven air distribution, thereby resulting in areas with stagnant air, temperature imbalances or uncomfortable drafts. Based on ASHRAE Standard 55: Thermal Environmental Conditions for Human Occupancy, ventilation should promote thermal comfort by avoiding excessive air movement directly on or around occupants while ensuring adequate mixing throughout the space. ASHRAE Standard 62.1 also emphasizes the importance of effective air distribution to achieve acceptable IAQ by ensuring that clean air reaches all occupied zones and contaminants are properly filtered and/or exhausted. Strategic placement of both supply and return grilles helps maintain proper air patterns, quickly diluting and removing airborne pollutants. This is particularly important in densely occupied or high-use spaces such as conference rooms, where sustained comfort and clean air are essential to health and performance.

When applying ASHRAE 62.1, it is also important to consider local building codes, particularly the mechanical code. Most building codes are based on ASHRAE standards for ventilation and IAQ; however, some local amendments or regulations may require stricter policies for distances from intake openings to contaminants or higher ventilation/exhaust requirements for higher-risk environments.

Positive, neutral and negative spaces

In the context of building space ventilation, the terms “positive,” “neutral” and “negative” refer to the pressure conditions within different areas or spaces within a building and their impact on airflow. A positive space has a higher air pressure than adjacent areas and results in air flowing out of the space when doors or windows are opened. Positive pressure is best used in areas where contamination prevention is critical, such as sterile rooms, operating rooms, server rooms or sensitive manufacturing environments. It ensures that airborne contaminants, such as dust, pollen or pollutants, are kept outside while maintaining a controlled and sterile environment. Maintaining a positive pressure requires careful air balancing to avoid excessive energy use or discomfort for occupants. It is essential to have proper filtration systems in place to ensure the incoming air is sanitized and that these spaces support both health and productivity, ensuring a safe environment for occupants.

Conversely, a negative space is when the air pressure inside a space is lower than in adjacent areas, causing air to flow into the space. The space is designed to contain and exhaust pollutants, making it suitable for areas like janitor closets and restrooms. Laboratories that handle biological agents, chemicals, dangerous substances and sensitive or sterile materials rely on negative pressurization to protect occupants against the spread of hazardous materials and contamination from the surrounding environment. Negative space is also ideal for areas where containment of chemicals, pathogens or other potentially hazardous materials is necessary, such as waste management areas. This helps ensure that harmful substances are contained within a space and do not escape into other areas of the building. Negative pressure is also beneficial for industrial workspaces where dust, fumes or chemicals need to be controlled. While effective for containment, negative space requires careful ventilation design to avoid issues with airflow and the introduction of external pollutants.

Neutral spaces require the air pressure within the space to be equal to the pressure in adjacent areas. This pressurization type is ideal for general-use areas where a constant, balanced air supply is essential for comfort and is commonly used in office spaces, conference rooms and residential areas where there is no particular need to control the flow of air or prevent contamination. Neutral pressurization maintains a balance of pressure, ensuring that airflow does not favor one direction over another. It allows for efficient ventilation without excessive movement of air into or out of a space. Neutral spaces are beneficial because they simplify the process of balancing environmental factors and minimize the use of outdoor air, thus reducing energy consumption. It is important to understand when and where to use neutral pressure conditions for effective ventilation design, as it ensures that airflow patterns maintain energy efficiency and support the health and safety of occupants.

Balancing supply, return, exhaust and outdoor air

Achieving proper IAQ and ventilation efficiency requires a well-balanced integration of supply, return, exhaust and outdoor air throughout the entire building system. Supply air delivers conditioned ventilation to occupied spaces, ensuring thermal comfort and contaminant dilution. Return air recirculates a portion of indoor air back to the HVAC system for reconditioning, improving energy efficiency. Exhaust air removes pollutants, moisture and odors from spaces such as restrooms and laboratories, preventing cross-contamination. Outdoor air is used to meet ASHRAE 62.1 ventilation requirements to maintain healthy air quality.

Improperly balanced components can cause overall system imbalances, thermal discomfort, inadequate ventilation and energy waste. It is important to calculate the airflow rates and air distribution to maintain the correct building pressurization and prevent unintended airflow paths that could compromise air quality and occupant comfort.

Examples of common system types for IAQ

The ASHRAE Handbook – Systems and Equipment discusses various system types for maintaining the desired ventilation/IAQ. It is important to choose the right system type for the space being ventilated.

Common systems used for heating and cooling administration-type buildings or areas include split system direct expansion (DX), packaged rooftop units and exhaust fans. Split system DX consists of two main components: an indoor unit, also known as an air handler, and an outdoor unit, also known as a condenser or heat pump. Additional outdoor air can be introduced into the split system indoor air handling unit by installing a louver on the outside of the building and interlocking it with the system it is supplying. Ductwork is then extended from this louver to the return ductwork for the system, allowing outside air to be pulled into the system when necessary. This would be controlled with a damper that only permits outdoor air during occupied hours, which in turn prevents energy waste. This setup can use exhaust fans to help bring more air into the administration-type building spaces, such as restrooms, janitor closets and locker rooms. Each space is required to exhaust fumes or excess moisture. These spaces are either continuously exhausted and connected to a time-of-day control or intermittently exhausted and connected to an occupancy sensor. The time-of-day control runs the exhaust fan continuously during set occupied hours for the building. The occupancy sensor recognizes when the room is occupied and then triggers the fan to turn on.

Another option for administration-type buildings is a packaged rooftop unit (RTU), which is one single unit that can handle the capabilities of both an indoor and outdoor unit. Outdoor air can be brought directly into the unit, controlled by either a manual- or motor-operated damper. This option does not require additional louvers or outdoor air ductwork. Instead, it only requires an outdoor air section at one end of the unit. Many modern RTUs also support energy recovery features and demand-controlled ventilation, which can improve energy efficiency and IAQ. Because of the rooftop location, these units save valuable indoor space and simplify zoning for multiple areas within a building.

Because chemicals are used in various tests, lab spaces within water treatment plants employ fume hoods connected to an exhaust fan on the roof. This type of exhaust fan is designed to direct any potential fumes or chemicals at a higher elevation than regular exhaust fans. The rooftop elevation reduces the potential for exhausted air to reenter through other equipment supplying air into the building and creates a safer environment around the fan when maintenance or service is required. Labs often warrant 100% outdoor air to ensure there is no mixture of air between space types, including adjacent labs. This can be done using a dedicated outdoor air system (DOAS) that is separate from the conditioning system. Unlike a packaged rooftop unit or split DX system, a DOAS does not reuse return air from each space, but instead supplies ventilation every time it is needed. Some system types provide conditioning to these spaces, such as a variable refrigerant flow system. This is especially beneficial as each space tends to have different temperature requirements that depend on what is being stored and which equipment is being used. To balance the airflow for lab systems, the outdoor air supply should be less than the exhaust required from the fume hoods within the space. As discussed above, this ensures contaminants, odors and fumes do not flow from the space into another.

Natural ventilation

Though all the above-mentioned examples involve mechanical ventilation, there are also natural ways to ventilate a space. The most basic form of natural ventilation involves air that enters or exits a space through open doors or windows. This type of ventilation is employed in spaces where people are constantly entering and exiting, such as an indoor waiting area for a bus station. Other natural ventilation methods are: (1) placing a louver on the outside of a building, not connected to any system with ductwork, designed to be manually opened or closed as necessary, and (2) installing a gravity ventilator on the roof above the space being ventilated. These methods work by pressurizing the difference between the outside and inside. As hotter air in the space rises, it exits and then lets in cooler air through the ventilator. However, natural ventilation is not the most reliable choice because the specific amount of airflow may not be controllable. Some areas may also experience extreme climate conditions, making the outside air too cold or hot. Rainy conditions may prevent doors or windows from being opened often enough.

Delivering quality indoor air hinges on understanding and applying key principles across the entire ventilation design process. ASHRAE Standard 62.1 provides a foundational method for calculating the minimum ventilation and exhaust requirements for various space types, ensuring that each zone receives adequate outdoor air based on occupancy and space function. Recognizing when to use positive, neutral or negative pressurization is critical for maintaining air quality and safety. Positive spaces protect clean zones, neutral spaces offer comfort and balance, and negative spaces contain contaminants. A successful system also requires careful balancing of supply, return, exhaust, and outdoor air across all zones within a building. This balance helps maintain pressurization targets, prevents unwanted airflows and supports energy efficiency. When these elements are integrated cohesively, ventilation systems meet code requirements and enhance occupant health, comfort and overall building performance.