To avoid arc flash incidents, electrical engineers must understand the codes, standards and design requirements when designing for arc flash mitigation. Read this Q&A for more information.

During this presentation titled “How to Design for Reduced Incident Energy Exposure,” electrical engineers learned how to design to help prevent arc flash incidents and minimize the severity of events when they do occur. This will include ensuring designs meet NFPA 70: National Electrical Code (NEC) as well as NFPA 70E and IEEE 1584.1.

Expert presenter Kyle Kocarek, Product Manager, Power Systems, Schneider Electric, responded to several questions that were not addressed in the Aug. 31, 2022, event.

Does 1-cycle still have light flashing and pressure wave?

AC short circuit currents have an asymmetrical component. The first few waves have a DC offset as well as highest peak causing the greatest stress on the system. As soon as an arc exists, light and pressure are created, though the intensity of these will vary with duration.

Is remote operation available for all switchgears?

All air circuit breakers (Masterpact line) that are used in switchgear can be configured for remote operation. Please contact your nearest Schneider Electric’s consulting engineer specialist. Depending upon the construction of the gear, complete remote operation to limited remote operation can be achieved by variety of means. (Remote operator for racking in and out, remote operation for turning breaker ON or OFF, remote operation via communication etc.).

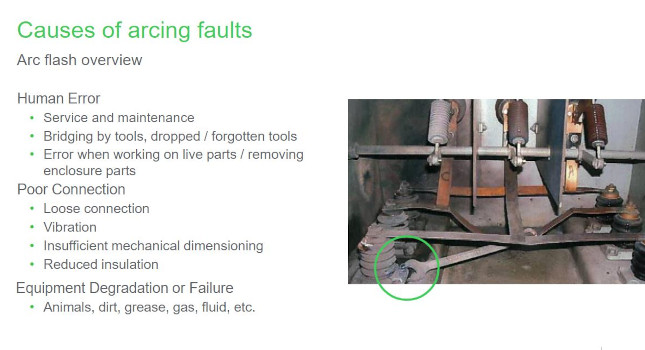

Is there an arc flash risk when switching breakers?

Arc Flash risk exists in all modes of energized work either due to human error, mechanical mal function, external environmental factors etc. A thorough report that has been published at the Electrical Safety Conference titled Electrical Injuries and Fatalities: Facts, Myths and Unknowns by Gordon that states There is no case found of significant arc flash injury operating a breaker.

Is ArcBlok CSA or ULc rated (for Canadian applications)? Any installs in Canada?

ArcBlok is cUL rated.

Does ArcBlok allow the entire switchboard to have lower IE rating on the label?

ArcBlok just impacts the line side/incoming. It does not impact the downstream load side. We recommend using in conjunction with something on the load side. The 1.2cal/cm2 label only pertains to the line side. A study still has to be done for the rest of the lineup.

Not exactly sure how you think awareness is higher on the pyramid than PPE.

Awareness being knowing the administrative controls, understanding the equipment, understanding the engineering controls they have to interact with. Someone could have all the PPE they want, but if they don’t know what they’re dealing with and how to work safely, then there’s a chance that PPE will not help them. PPE should be a last line of defense.

Explain the difference between a virtual main and ArcBlok?

Biggest difference is ArcBlok is a passive form of protection whereas Virtual main still relies on upstream OCPD to trip based on a byproduct of an Arc or some other triggering signal.

ArcBlok – But it does nothing downstream of the main c/b correct?

Correct, ArcBlok only impacts the incoming line side/zone 1. it does not impact load side/downstream at all.

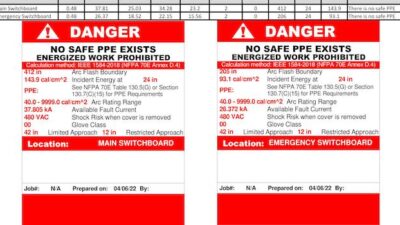

Do we need two arc flash labels for Emergency and normal power?

Depends on the end-user policy. A lot just use worst case AFIE.

What about electrode/conductor configurations? VCB versus HCB?

Different electrode configuration can reduce arc flash hazard as described in the latest IEEE 1584. However again these will do little to mitigate risks on the line side of the device.

How does differential protection help with reduce fault clearing time?

Differential protection enables more sensitive fault detection by comparing the currents at two points on a system. Often lower-level faults are either of not sufficient magnitude to cause a breaker to trip or will cause the breaker to trip in the overload region (L) not in the Sor I region. The goal for arc flash protection is to clear the fault as quickly as possible. Differential protection being more sensitive in detecting the fault can trigger to clear the overcurrent protection device without waiting for the OCPD to respond based on its own pickup settings.

In ERMS mode, how fast does it allow for arc fault clearing? 1/4 wave or longer?

ERMS mode means no intentional delay. Instantaneous time zone. Instantaneous zone is generally defined by response of less than 0.1second (100msec) or 6 cycles. Although many breakers will react within 3 cycles, there are other dynamics involved such as relay / trip unit detection and activation time, signaling time, breaker commit time and fully cleared time (lower and upper limits of the Instantaneous time current curve band). ERMS clearing time is 50 ms assuming the pickup setting is set below the arcing current of the system. A power systems study is necessary to ensure that the arcing current will activate the ERMS.

What is virtual main?

Essentially protection for MLO gear. A virtual main is a circuit breaker on the primary side of the upstream transformer (typically a MV vacuum circuit breaker) that is owned by the end user. Meaning the end user can open the vacuum circuit breaker. https://www.se.com/us/en/download/document/1910BR1302/

If we have two main feeders, does that mean we need ArcBlok for each main breaker?

If there are multiple sources and therefore multiple main circuit breakers. Using ArcBlok for the line side risk of each source would be required to reduce the line side risk of each source.

How do you model the ArcBlok in SKM or ETAP? Is there a clearing time maximum?

We will have ArcBlok in ETAP 22.1 which will release by end of year. This will be a preliminary quick add where either they allow for a checkbox for 1.2cal bus or something similar…waiting to hear back final solution.

Long term (ETAP 23 releases a year from now) they will add Energy Reducing line Side Isolation device to library (That is part of a specific circuit breaker). And checking this box will give the line side 1.2cal.

We have begun talks with SKM and EasyPower but aren’t as far along yet.

How does ArcBlok minimize incident energy and/ or extinguish an arc?

It reduces the likelihood of an event because it is an isolated vault. And then the insulated barriers separate the lugs, which is where the arc can form. The arc has to travel 7 down and 7 back up around the barriers in order to form. It becomes elongated/spindly/weak and cannot sustain itself so it extinguishes.

MMS?

Maintenance mode switch.

What about maintenance mode switches?

Maintenance mode switches are good one size fits all approach with the most simplistic visual confirmation of something has been done to mitigate arc flash hazard. However, note Maintenance mode switches are typically always responding to a short circuit condition not necessarily an arc flash hazard condition. Also, MMS do not isolate or mitigate the energy on the line side.

Does ArcBlok have any effect, positive or negative, on power quality?

No, it is passive. No impact to performance or power quality.

So, Operator would fall under Admin Controls in the pyramid?

Operator will implement the Administrative Controls. Administrative Controls are lockout/tagout, training and correct equipment. Per NPFA 70E – Administrative Controls are described as administrative controls are typically employed when hazards are not controlled. Much of Chapter 1 discusses the use of effective administrative controls, including procedures, employee training, risk assessment, job briefing, auditing and the use of energized electrical work permits (EEWPs). Establishing an ESWC is possibly the most recognized administrative control addressed in NFPA 70E. Employee commitment is heavily relied on with the use of administrative controls.

Does SKM, ETAP and EasyPower (or rewrite to pick one that was not covered) power system design software includes ArcBlok?

We will have ArcBlok in ETAP 22.1 which will release by end of year. This will be a preliminary quick add where either they allow for a checkbox for 1.2cal bus or something similar…waiting to hear back final solution.

Long term (ETAP 23 releases a year from now) they will add Energy Reducing line Side Isolation device to library (That is part of a specific circuit breaker). And checking this box will give the line side 1.2cal.

We have begun talks with SKM and EasyPower but aren’t as far along yet.

What happens at 1.2 cal/cm2?

Per NPFA 70E – Testing has concluded that 1.2 cal/cm2 is the level at which exposed skin can suffer the onset of a second-degree burn. 1 Cal/cm2 of incident energy will raise 1 gram of water 1 degree Celsius. The onset of second-degree burn can occur at 1.2 Cal/cm2. Many people use the analogy of 1.2 Cal/cm2 being equal to holding a finger over a flame for one second.

Have you heard of new developments and potential release of IEEE 1814?

Recommended Practice for Electrical System Design Techniques to Improve Electrical Safety. Please consult IEEE.

There was mention of Arc Resistant gear only being good for a single event. Are there instances that the equipment would not require full replacement, for example manufacturer inspection, partial replacement, etc. that would allow the equipment to be put back in service with confidence from the manufacturer?

Please consult your nearest Schneider Electric’s consulting engineer specialist as this is a very broad topic. Depends upon the amount of damage, intensity of arcing event and the type of construction and the location of fault etc.

What are the practical ways of reducing fault current without adding capital cost to the project?

Please consult your nearest Schneider Electric’s consulting engineer specialist as this is a very broad topic. Existing, retrofit versus new installations each will have its own methodology.

What factors have the biggest effect on incident energy when designing? Length of wires? Conductor configuration?

(missing response?)

I am wondering how to reduce incident energy in a project. Where do you start?

Please consult your nearest Schneider Electric’s Power System Engineering specialist and we will be happy to assist you. Per IEEE 1584. The most significant factors that influence incident energy are the arcing current, arc duration and working distance. Minimizing the arcing current and arc duration are factors that you can influence. Avoiding conductors in a horizontal configuration will help reduce incident energy.

How does equipment electrode configuration affect arc flash severity and what are the recommended dimensions that we could use for modeling disconnects, panelboards, switchboards and switchgear for arc flash study?

Please consult your nearest Schneider Electric’s Power System Engineering specialist. And IEEE 1584-2018. IEEE 1584 – 2018 provided default dimensions for different types of electrical equipment. See Table G.18—Enclosure sizes for IEEE 1584-2018 arc-flash model.

How does the maintenance mode switch reduce the level of incident energy? What are you losing in your system performance while you are in maintenance mode?

Please contact your nearest Schneider Electric’s consulting engineer specialist for a detailed explanation. However, in most cases due to selective coordination requirements, many breakers have intentional delay introduced by system design engineers to allow downstream breakers to clear the fault. MMS switches temporarily removes these intentional delays and makes the breaker trip fastest it can (instantaneous) when it detects any fault. Downside is that one loses selectivity during the time the switch is ON. Instantaneous zone is generally defined by response of less than 0.1second (100msec) or 6 cycles. Although many breakers will react within 3 cycles, there are other dynamics involved such as relay activation time, breaker commit time and actual clearing time etc.

How should we revise our specs to include arc flash protection in the equipment we spec?

Please contact your nearest Schneider Electric’s consulting engineer specialist.

Do you see more people using MCCs equipped with feeder breakers due to the equipment construction and inherent increased safety by design?

Please note that each of these products have different standards, available options and testing requirements. UL 845, UL 891 and UL 1558 have their own distinct testing construction temperature rise and wiring requirements.

How much cost does the ArcBlok add to a 1600A MCC?

Should be ~15% adder compared to average MCC lineup.

Is ArcBlok only for switchboard and switchgears?

Switchboard and Motor control centers.

You say 18 for panels and 24 for switchgear. What is the distance for switchboards?

Switchboards 18.

Is there a monitoring unit on the Arc Blok to track the number events?

There is a mechanical plugger event indicator that can send signal with a simple relay powered by the lineup control power to send a variable indication signal to a pilot light, BMS, etc.

What section of Occupational Safety and Health Administration, specifically, requires arc flash protection?

Title 29 of the Code of Federal Regulations (29 CFR) part 1910.

How much cost is added for the ArcBlok feature for a 4,000-amp, 480/277 volt, 3-phase switchboard?

Today we can only go up to 2500A. We are working on expanding the amperage range in the next 12 months.

Can ArcBlok be retrofitted to existing equipment from different manufacturers?

Yes! ArcBlok 2500 can be retrofitted into existing switchboards and motor control centers. It requires 30 wide main section. If that doesn’t exist, Schneider Services can add a main section.

Can the ArcBlok be modeled in an arc flash study?

Yes, we are working on integrating it into ETAP, SKM, EasyPower. We will have ArcBlok in ETAP 22.1 which will release by end of year. This will be a preliminary quick add where either they allow for a checkbox for 1.2cal bus or something similar…waiting to hear back final solution.

Long term (ETAP 23 releases a year from now) they will add Energy Reducing line Side Isolation device to library (That is part of a specific circuit breaker). And checking this box will give the line side 1.2cal.

We have begun talks with SKM and EasyPower but aren’t as far along yet.

Do you see more people using MCCs equipped with feeder breakers given the long lead time of Switchboards and Switchgear?

Yes, we’ve seen this in some cases.