NFPA 70: National Electrical Code (NEC) codifies the requirements for safe electrical installations into a single standardized source.

Learning objectives

- Learn what NFPA 70: National Electrical Code (NEC) is and how electrical engineers might reference it..

- Understand how to interpret and use the NEC for electrical installations.

- Review the basics of the different chapters of the NEC.

NEC insights

- Updated every three years, the NFPA 70: National Electrical Code (NEC) is enforced differently across states and jurisdictions, with the 2023 NEC currently adopted by some states while others continue using earlier editions.

- Within the NEC, each article is subdivided into parts and sections that prescribe detailed requirements for topics such as grounding, overcurrent protection, conductor sizing and equipment installation to ensure electrical safety and reliability.

NFPA 70: National Electrical Code (NEC) is a code in the United States used for the safe installation of electrical equipment and is intended to provide installations essentially free of hazard. The NEC is not a law or design guide or even an instruction manual for untrained people.

Although the NEC is not a law, the NEC and other NFPA codes and standards are adopted and enforceable by most states and various jurisdictions outside of the United States including Mexico, Venezuela, Costa Rica and Columbia. It is one of the many code series of books published by the NFPA, “a benchmark for safe electrical design, installation and inspection to protect people and property from electrical hazards.”

The NFPA website should be consulted to determine the version of the NEC being enforced locally. The information that follows is based on the 2023 NEC.

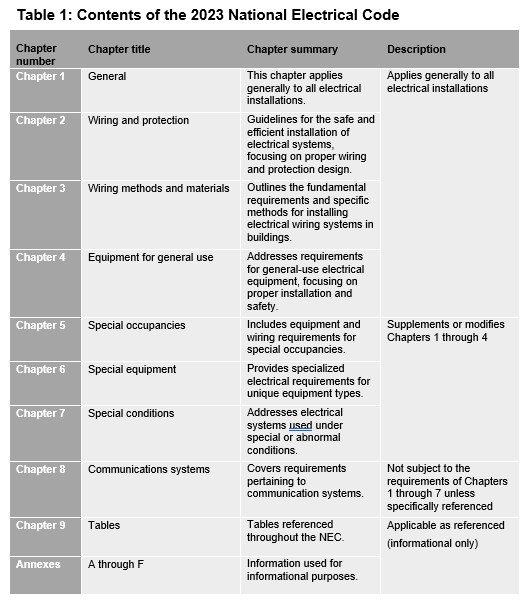

The NEC is structured and organized into segments for ease of use and application. There are nine chapters that focus on specific topics. Each chapter contains multiple articles and each article is divided further into parts and sections.

For instance, Chapter 2 (wiring and protection) Article 242 (overvoltage protection) contains eight parts, and Part 1 has three sections (242.1, 242.2 and 242.3). NEC Chapters 1 through 4 present definitions and introduce the foundational aspects of electrical installations, including rules, methods and materials. Chapters 5 through 7 expand on this understanding by focusing on more specialized areas and equipment of electrical installations.

Chapter 8 covers communication systems and Chapter 9 contains various tables that are referenced throughout the code and can be used for reference. Informative Annexes A through K are for informational purposes and are not enforceable. Table 1lists the contents of the 2023 NEC.

The NEC begins with Article 90. This article introduces the code. It states the intent of the NEC, the areas to which the NEC applies and how the NEC is arranged. It discusses how the NEC is enforced and includes mandatory and permissive rule language clarifications, the process for obtaining formal interpretations of the code, procedures for examining equipment for safety and planning for future proofing wiring installations.

For example, Article 90.4(D) recognizes that new products, constructions or materials contained in the 2023 edition may not be available when the edition is adopted, so the authority having jurisdiction may allow those things specified in the previous adopted edition to be used instead.

NEC Chapters 1 through 3

Chapter 1 of the NEC is a general chapter containing two articles: Article 100 and Article 110. Article 100 contains definitions essential to the application of the code. Article 100 was significantly changed in the 2023 edition to organize definitions into one article (versus previous editions that provided definitions in various articles). For article-specific definitions in the 2023 NEC, the specific article is still listed in parenthesis at the end of the definition for ease of use.

Article 110 is the foundation for interpreting and applying the NEC correctly. This is a frequently used chapter when designing electrical systems. Understanding this article is essential, as it focuses on providing safe installations for the installer and end users. Key components of this article include examination, identification, installation, use and product listing (certification) of equipment; mechanical execution of work; conductor materials, terminations and splicing; equipment markings; disconnecting means; enclosure types; available fault current; and spaces about electrical equipment.

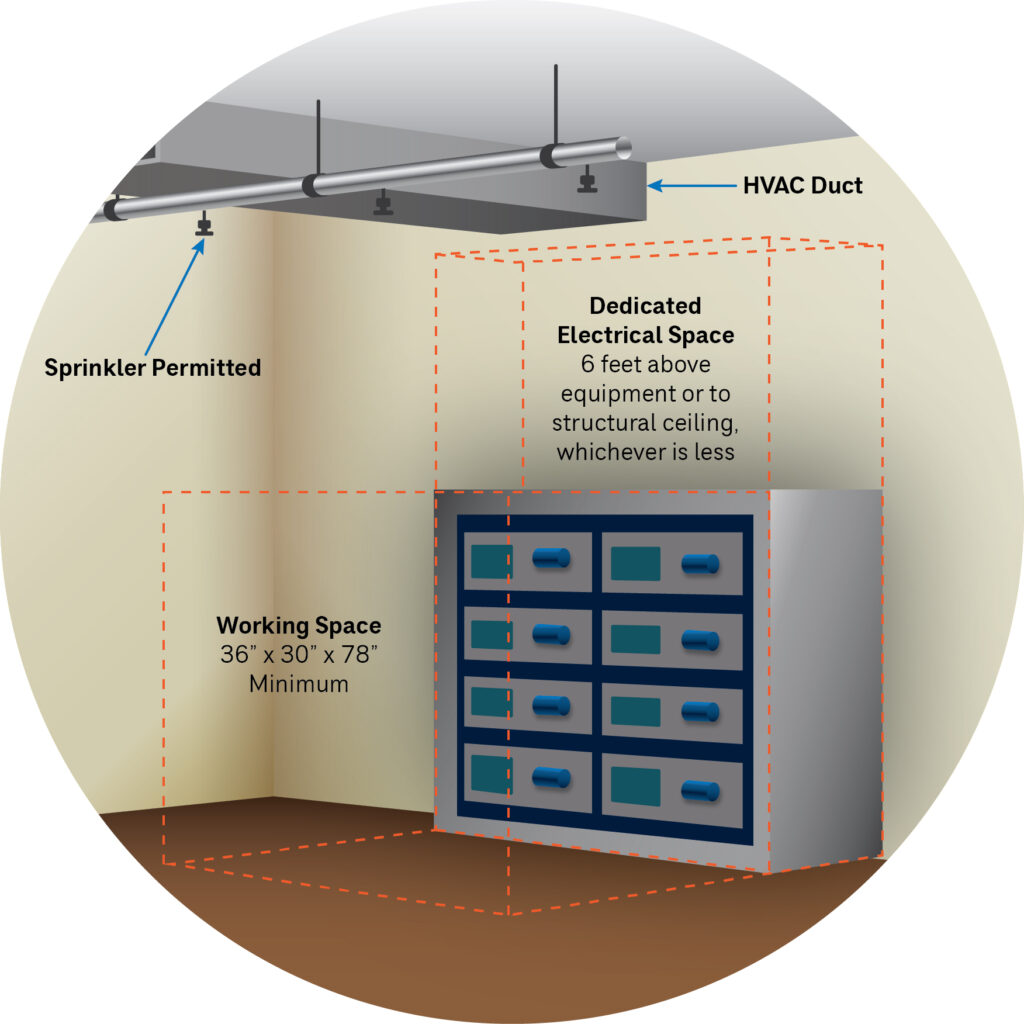

Applying the components of this article keeps people safe. The importance of clear and accessible working space around electrical equipment cannot be emphasized enough. Article 110 provides width, depth and height dimensions for electrical spaces and prescribes dedicated spaces for access, protection and maintenance of equipment. The minimum depth for clear working space is dependent on three conditions:

- Condition 1 specifies the space may have an exposed live part on one side and no live or grounded parts on the other side.

- Condition 2 specifies the space may have exposed live parts on one side and grounded parts on the other side.

- Condition 3 specifies the space may have exposed live parts on both sides.

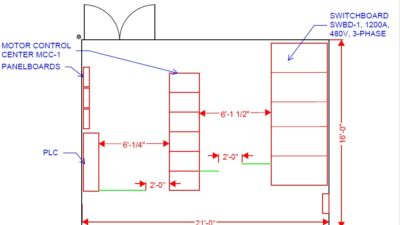

The height of the working space in relation to electrical equipment and other equipment is defined, along with specifications for access to and egress from working spaces. Part II of Article 110 lists the specifics for electrical systems rated 1,000 volts (V) nominal or less, and Part III lists requirements for electrical systems rated over 1,000 V. This paper focuses on systems 1,000 V and less and does not address the requirements for each voltage class (see Figure 1).

NEC Chapter 2 includes several key articles that provide guidelines for the safe and efficient installation of electrical systems. Proper wiring and protection design ensures safe and efficient power distribution throughout a building. Article 200 centers on the use and identification of grounded (i.e., neutral) conductors, making sure they are distinguishable from ungrounded (i.e., hot) conductors.

Article 210 encompasses branch circuits. It defines types of branch circuits and specifies requirements for circuit ampacity, receptacle placement and receptacle protective measurements such as ground-fault circuit interrupters (GFCIs) and arc-fault circuit interrupters (AFCIs) protections in specific locations.

Article 215 establishes guidelines for feeders, including ampacity requirements, conductor sizing and overcurrent protections. It also details routing and support requirements.

Chapter 2 continues with Article 220, which outlines requirements for branch-circuit, feeder and service load calculations. This article provides methods for calculating electrical loads including applying demand factors for efficient system designs.

Article 225 governs electrical wiring systems running outdoors between structures and includes requirements for height clearances, physical protection and weatherproofing.

Article 230 encompasses service entrance conductors, which are defined as the electrical power that enters a building from a utility source. While Articles 200 through 230 are pertinent to circuits 1,000 V alternating current (ac) or less (considered low voltage), Article 235 governs branch ‑circuit, feeder and services over 1,000 Vac (considered medium voltage).

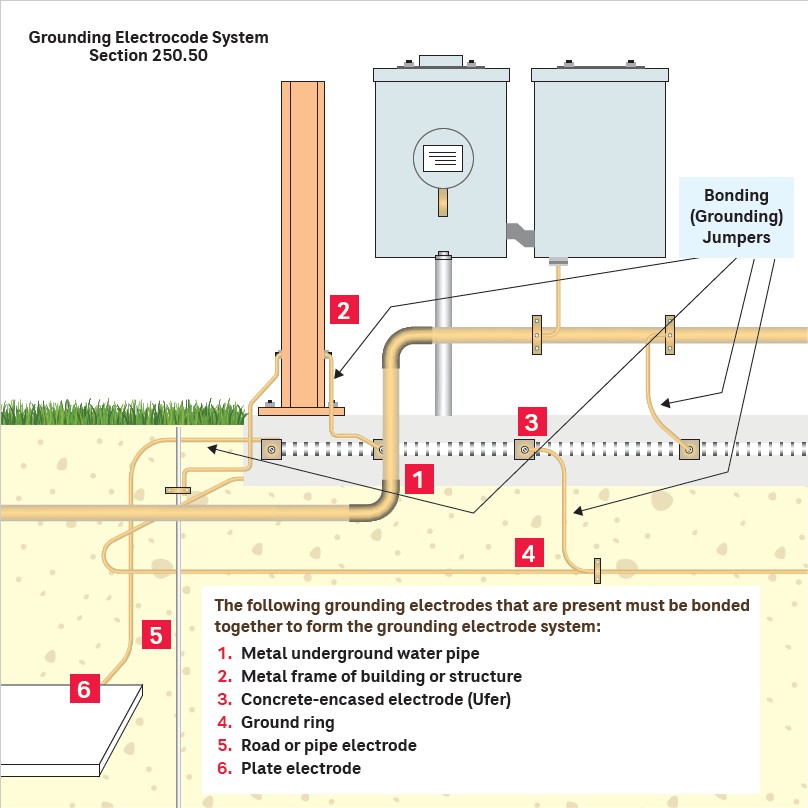

Article 240 details requirements for overcurrent protection including the selection and installation of fuses and circuit breakers. Article 250 explains grounding and bonding practices to prevent electric shock and reduce the risk of fault currents. Electrical system grounding is critical to safety as it provides a safe path for electrical energy to ground in the case of a fault or an abnormal condition. Chapter 2 is one of the most detailed and safety-oriented chapters in the NEC, to ensure the safe operation and maintenance of electrical systems (see Figure 2).

NEC Chapter 3 outlines the fundamental requirements and specific methods for installing electrical wiring systems in buildings. It begins with Article 300, which sets the groundwork for safe wiring practices including protecting conductors from physical damage, maintaining separation from nonelectrical systems like piping and ensuring adequate working space and support. It also covers underground wiring installations, such as minimum burial depths and sealing of raceways, to prevent moisture ingress.

Article 310 focuses on the use of insulated conductors, detailing acceptable insulation types, voltage ratings (typically up to 2,000 V) and ampacity based on conductor material, size, insulation class and environmental factors. Adjustment and correction factors must be applied in cases like multiple conductors in a raceway or in elevated ambient temperatures.

Article 312 addresses enclosures such as cabinets and meter sockets, specifying the construction quality, mounting, labeling and space needed for proper conductor bending and termination. Article 314 expands on the installation of boxes (outlet, pull and junction types), highlighting volume calculations (box fill), secure mounting and accessibility for splicing and maintenance. Conductors must have enough length for termination and entries must be fitted to prevent abrasion.

Articles 320 through 399 describe individual wiring methods including armored cable, metal-clad cable, flexible and rigid conduits and nonmetallic raceways. Each article covers the permitted uses, installation guidelines, securing methods and physical protection needed for that type of wiring.

Topics also include specialty cables, such as underground feeder, mineral-insulated and optical fiber cables, to ensure materials are selected based on application and environmental exposure. Collectively, Chapter 3 provides the technical foundation to design and install electrical wiring that is code compliant and suited to the physical conditions of the space, while balancing performance, safety and durability.

The importance of NEC Chapter 4

NEC Chapter 4 addresses requirements for general-use electrical equipment, focusing on proper installation and safety. Articles 400 and 402 cover flexible cords and cables and fixture wires, restricting their use to portable or temporary applications and specifying suitable types such as service junior thermoplastic cable and service, oil-resistant, outdoor and weather-resistant cable. The articles prohibit routing cords through walls or doors and emphasize ampacity limits, strain relief and grounding.

Article 404 outlines rules for switches, including general-use, dimmer and specialty types that require proper grounding, accessibility and appropriate ratings for disconnecting circuits or equipment.

Article 406 covers receptacles and plugs, mandating tamper-resistant devices in residential and child-occupied locations, weatherproofing for outdoor use and protection via GFCI or AFCI based on the area.

Articles 408 and 409 focus on switchboards, switchgear, panelboards and industrial control panels, requiring clear circuit labeling, appropriate working clearances and secure busbar connections. The articles also include provisions for overcurrent protection and proper grounding of panel assemblies.

Articles 410 and 411 provide standards for luminaires, requiring light fixtures to be properly supported, marked for lamp ratings and installed with consideration for recessed applications. Wiring methods must also prevent mechanical stress or overheating.

Articles 422 through 427 address electrical appliances and fixed equipment, such as space heating equipment, regarding disconnecting means, overcurrent protection per the nameplate and safe grounding practices.

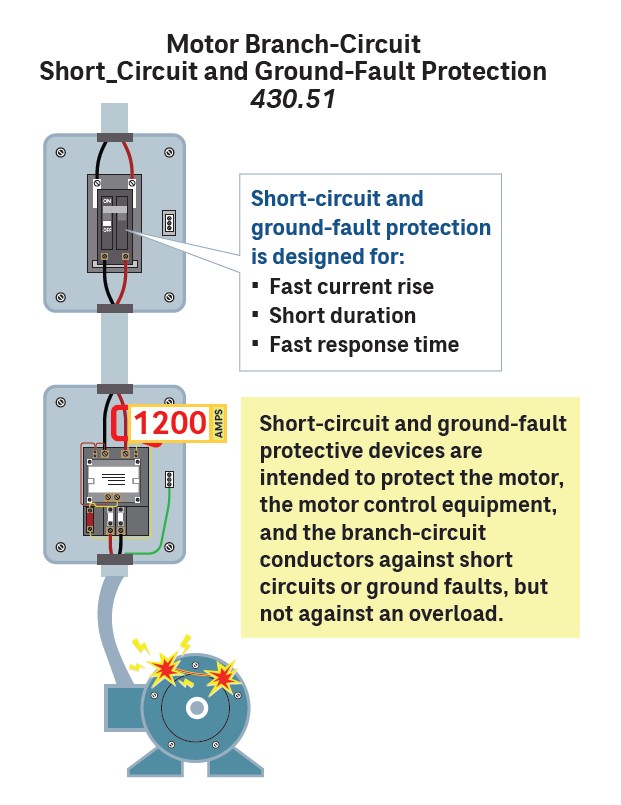

Chapter 4 continues with safe and efficient operation practices for certain types of equipment. Article 430 focuses on motors and their control systems, including circuit conductor sizing (typically 125% of full-load current), short-circuit and overload protection and proper disconnect placement. Article 430 ensures controllers are matched to motor ratings for horsepower and voltage.

Article 440 provides requirements for the safe installation and use of air-conditioning and refrigeration equipment.

Articles 445 and 450 govern safe practices for generators, transformers and transformer vaults including ratings, installation guidelines, grounding and protective measures.

Articles 455, 460, 470 and 480 cover the use and installation of phase converters, capacitors, resistors and reactors and storage batteries.

Article 495 defines safe installation practices and use of equipment over 1,000 V. Overall, Chapter 4 ensures that everyday electrical equipment, ranging from lighting and receptacles to motors and appliances, is installed and protected in a way that minimizes hazards and ensures long-term system reliability.

NEC Chapters 5 through 7

Chapter 5 addresses special occupancies, such as hazardous (classified) locations, health care facilities, park trailers, assembly occupancies and other such spaces, and includes equipment and wiring requirements for these occupancies. Articles 500 through 506 apply to hazardous locations where combustible gases and vapors, ignitable fibers or combustible dusts may be present that can potentially cause explosions or fire.

Each occupancy area is divided into three classes with further divisions and zones:

- Class 1 locations have flammable liquids or vapors present.

- Class II locations contain flammable dust.

- Class III locations contain fibers or flyings.

Each area includes specific conditions that require special precautions and requirements for electrical and electronic equipment and wiring. For instance, for Class I locations, Section 501.15 requires conduit seals to prevent the migration of combustible gases or vapors from a hazardous location to one with a potential source of ignition.

Articles 511 through 516 apply to areas or places that contain fuels, oils and paint-type solvents. These places include commercial garages, cannabis oil equipment and manufacturing facilities and aircraft hangars.

Article 517 pertains to health care facilities including hospitals and nursing homes.

Article 518 covers buildings, structures or places designed as gathering spaces for 100 people or more, including auditoriums, casinos, courtrooms and museums.

Articles 520 through 540 are for gathering places such as theaters, carnivals and television studios.

Articles 545 through 555 are for specific types of buildings or places such as agricultural buildings, mobile homes and marinas.

Article 590 applies to temporary installations.

NEC Chapter 6 provides specialized electrical requirements for unique equipment types to ensure safety, reliability and code compliance under various conditions. Article 600 covers electric signs and outline lighting, detailing how these systems must be constructed, wired, grounded and installed.

Articles 604 and 605 include safe practices for manufactured wiring systems and office furnishings.

Article 610 has information pertaining to cranes and hoists.

Article 620 outlines requirements for elevators, escalators and moving walks for power supply, control circuits, signal devices and lighting. These systems must remain safe under normal and emergency conditions; Article 620 therefore emphasizes fire recall features, accessible disconnecting means and dedicated machine room lighting and receptacles.

Articles 625 through 685 pertain to different types of systems and equipment and their use and installation requirements. For instance, Article 680 provides guidelines for the installation of electrical systems for swimming pools and fountains.

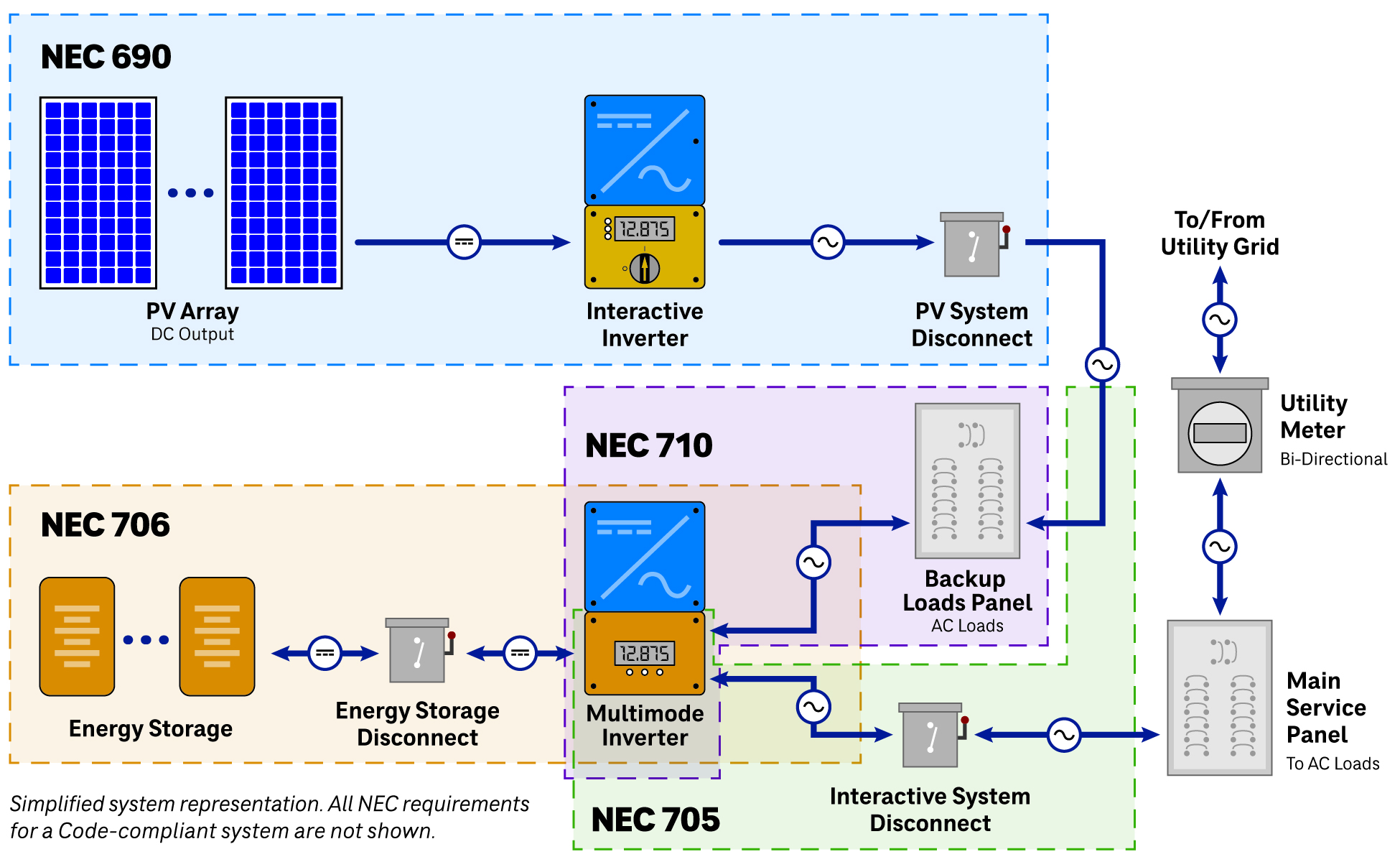

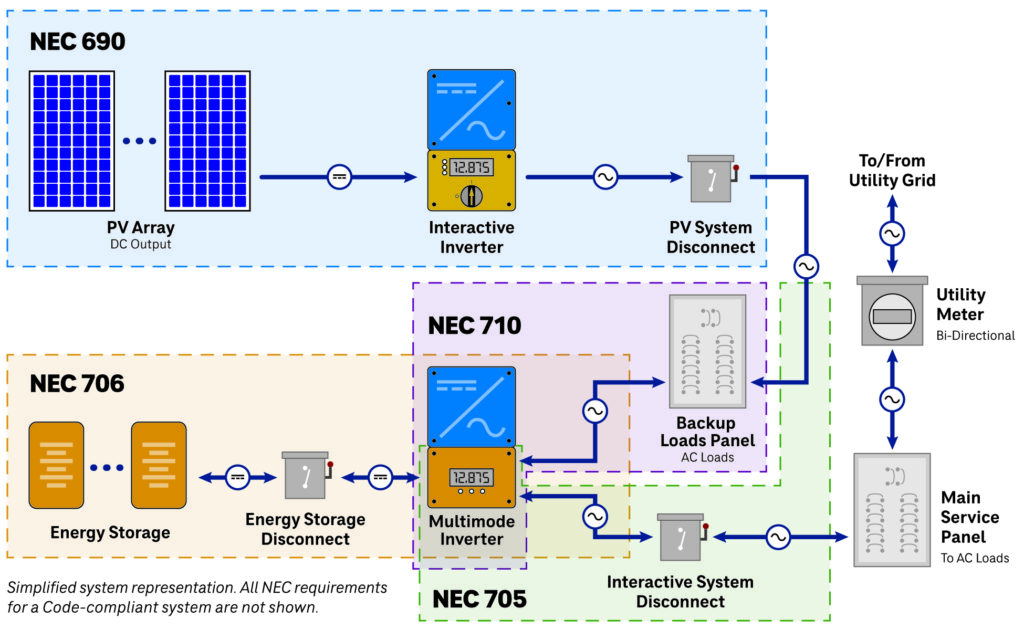

Articles 690 and 691 focus on solar photovoltaic (PV) systems, addressing installation of grid-tied, stand-alone and hybrid systems. It includes requirements for PV modules, inverters, conductors, disconnects, grounding, rapid shutdown (690.12) and system labeling.

Articles 692 and 694 focus on fuel cell and wind electric systems. The articles define requirements for wiring, grounding and protection to ensure a safe and efficient operating system.

Finally, Article 695 governs fire pump installations, requiring a dedicated and dependable power supply that can withstand fire conditions. Overcurrent protection must not interfere with pump operation during starting currents and wiring must be routed separately and protected from damage. Collectively, Chapter 6 ensures that specialized systems — whether for life safety, vertical transport, renewable energy or signage — operate safely, remain serviceable and perform as intended in critical environments.

NEC Chapter 7 addresses electrical systems used under special or abnormal conditions, including emergency systems, legally required standby, optional standby, fire alarm systems and critical operations power systems. The chapter focuses on reliability, continuity of power and safe operation during outages or emergencies. Circuit types and classes along with cable systems are discussed and installation requirements are listed for safe and reliable operation of these types of specialized circuits.

Article 705 specifically covers interconnected power sources, such as solar PV, wind turbines, generators, fuel cells and battery energy storage systems, that operate in parallel with the primary power source. It includes requirements for interconnection, overcurrent protection, labeling, anti-islanding and coordination to ensure safe operation with or without grid support. Chapter 7 ensures essential systems function safely under demanding conditions.

NEC Chapters 8 and 9, plus Annexes

NEC Chapter 8 addresses requirements pertaining to communication systems. Communications systems include telephones, radio and television antennas, satellite dishes, closed-circuit TVs, cable TV systems and network-powered broadband communications not under control of the utility. These systems are not covered in Chapters 1 through 4 nor in the specialty areas of Chapters 5 through 7 except where other chapters are specifically cited in Chapter 8.

NEC Chapter 9 consists of the tables referenced throughout the NEC. The tables pertain to conductor, cable and conduit properties including bend dimensions and raceway fill properties. Power source limitations for Classes 2 and 3 power supplies and for the power supplies of power-limited fire alarm systems are also specified.

Annexes A through K are not part of the enforceable NEC and while they are provided for informational purposes, they have significance. They provide information such as product safety referenced standards, example calculations, additional tables for the proper implementation of code articles and guidance to meet additional standards such as Americans with Disabilities Act standards in buildings.

The NEC Handbook is a companion guide to the NEC. It provides additional context, explanations and examples to help users understand and apply the code more effectively. The Handbook includes commentary from experts, illustrations and practical examples that clarify the intent and application of the code requirements. It is designed to be a helpful resource for electrical professionals, inspectors and engineers who need to interpret and implement the NEC in their work.

As an electrical engineer in the industrial consulting world, there are several critical parts of the NEC that are used more often than others to ensure safe and compliant electrical installations. Working clearances about electrical equipment is important during the design and installation process and requirements can be found in Article 110.

Breaker sizing is an important aspect of electrical design and is covered in various articles of the NEC including Article 240 for determining the appropriate size of overcurrent protection devices and Article 430 for guidelines on sizing circuit conductors and overcurrent protection devices for motors and their control systems.

Once overcurrent protection is designed Article 310 is used to size the conductors based on insulation type, voltage, ampacity and installation factors (such as routing underground or overhead). Article 250 provides guidance on the sizing of ground conductors based on the size of the service-entrance conductors or the feeder conductors.

Conduit type and sizing is covered in Chapter 3 and the tables in Chapter 9 pertain to conductor, cable and conduit properties, including bend dimensions and raceway fill properties. These are a few examples of the NEC that are used on a frequent basis when designing electrical systems.