Engineers must be aware of how to design electric vehicle charging stations and the impacts these stations have on overall design.

Learning objectives:

- Know the applicable codes and standards that impact the design of EV charging stations.

- Identify the different types of EV charging stations.

- Learn the design coordination points and respective disciplines when designing electric vehicle charging stations.

EV charging insights:

- Three specific articles under the NEC govern EV charging station design – Article 400, Article 625 and Article 750.

- Electrical engineers must coordinate with many other disciplines to ensure charging stations are functional and effective.

EV charging codes and standards

While there are several amendments, codes, ordinances, listings and standards regarding electric vehicle (EV) charging stations, electrical engineers must understand three specific articles within NFPA 70: National Electrical Code (NEC).

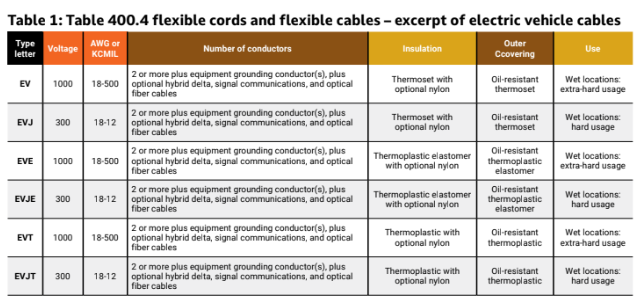

Article 400: Flexible Cords and Flexible Cables covers all requirements for flexible cords and cables, detailing the types of flexible cords and cables for EV charging stations. There are six types of flexible cords and cables specifically for EV charging stations: EV, EVJ, EVE, EVJE, EVT and EVJT. Table 1 is an excerpt from Table 400.4 of the NEC, with descriptions for each of the six types. Other types of flexible cords and cables can be utilized as EV cables, but require permission from the authority having jurisdiction.

Article 400 also has two tables – Table 400.5(A)(1) and Table 400.5(A)(2) – with ampacity requirements for flexible cords and cables based on the conductor size, type and assumption of an ambient temperature of 30 degrees Celsius (86 degrees Fahrenheit).

Article 625: Electric Vehicle Power Transfer System covers the electrical conductors and equipment connecting an EV to wiring on the premises to charge, power export or bidirectional current flow. The EV power transfer system equipment shall be listed and must be powered by one of the following voltages:

- Alternating current system voltages of 120, 120/240, 208Y/120, 240, 480Y/277, 480, 600Y/347, 600 or 1000.

- Direct current system voltages of up to 1000 V.

If the electric vehicle supply equipment (EVSE) needs to be plugged into a receptacle on the premises, then the cable for the cord-connected EVSE must either be one of the six flexible cords and cables mentioned above or a hard service cord, junior hard service cord or portable power cable type. All these additional flexible cord and cable types mentioned are also in Table 400.4, Table 400.5(A)(1) and Table 400.5(A)(2) of the NEC with requirements specified.

The length of the cable between the receptacle and the EVSE varies depending on the location of the interrupting device of the personnel protection system. If the interrupting device is within the enclosure of the EVSE, and the EVSE is portable, then the power-supply cord cannot be more than one foot in length. If the interrupting device is within the enclosure of the EVSE, and the EVSE is fastened in place, then the power-supply cord cannot be more than six feet in length and should not be in contact with the floor when connected to the receptacle. If the interrupting device is located at the attachment plug or is within one foot of the power-supply cord, then the overall cord length cannot be more than 15 feet in length.

The output cable, which is the cable between the EVSE and the EV, must be one of the six EV cable types mentioned above or an integral part of the EVSE. Its overall length cannot exceed 25 feet in length, unless the EVSE has a cable management system.

EVSE is required to have a listed personnel protection system against electric shock. While a standard ground fault circuit interrupter device can protect cord-and-plug systems, other higher voltages need monitoring systems in the EVSE to confirm proper grounding is present and maintained during charging. A personnel protection system is not required if the EVSE supplies less than 60 volts direct current to the EV.

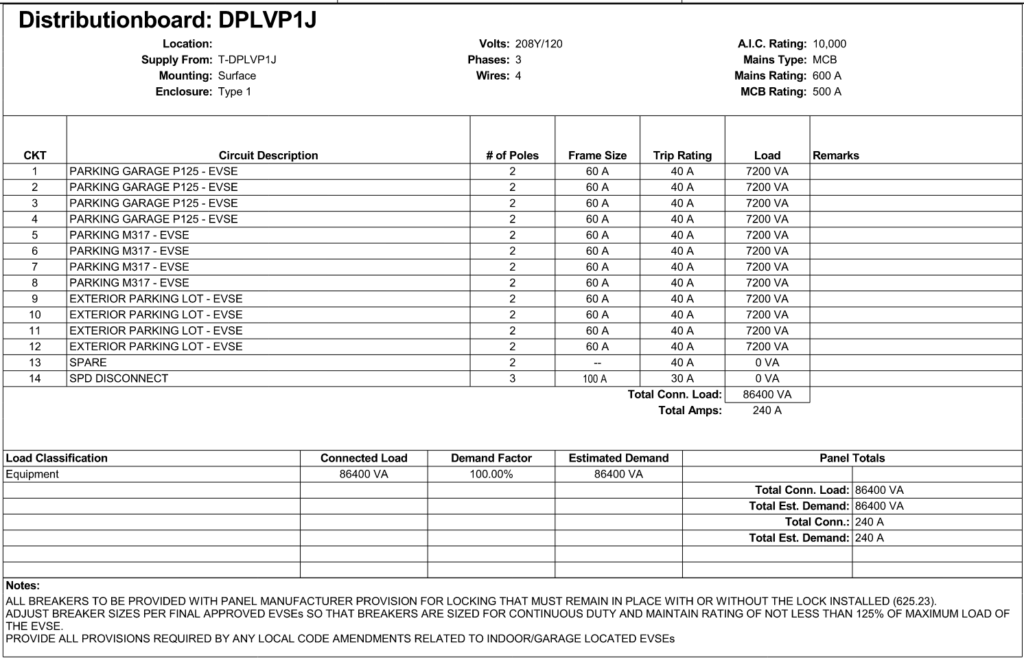

When designing the electrical distribution system on the premises, each EVSE greater than 16 amperes, or 120 volts, must have a dedicated branch circuit. The only exception is if the EVSE is a part of an overall energy management system on the premises or if it has adjustable settings. If either is the case, one branch circuit can feed multiple EVSEs. For overcurrent protection for feeders and branch circuits supplying EVSE and wireless power transfer equipment (WPTE), including bidirectional EVSE and WPTE, the overcurrent protection must be sized as a continuous load with a demand factor of 125%.

For EVSE and WPTE rated more than 60 amperes, or 150 volts to ground, requires a disconnecting means (lockable open per Article 110.25). The location of the disconnecting means must be in an accessible location. It is acceptable to remotely locate the disconnecting means from the EVSE, but the EVSE must have a plaque that states where the disconnecting means is located.

There are three types of EVSE and WPTE when designing electric vehicle charging stations: portable, fastened-in-place and fixed-in-place. Article 625 requires portable and fastened-in-place EVSE to be connected by a non locking, grounding-type receptacle. For fixed-in-place EVSE and WPTE, this equipment must be permanently wired and fixed in place to the supporting surface. For fastened-in-place and fixed-in-place EVSE, the coupling means of the EVSE must not be at a height less than one and a half feet above the floor level for indoor locations or two feet above the grade level for outdoor locations. There are no height requirements for portable EVSE.

EVSE or WPTE that has a power export function and is part of an interactive system is called interactive equipment. Some examples of interactive systems include: an optional standby system, an electric power production source or a bidirectional power feed. If the EVSE or WPTE is considered interactive equipment, these components can be a part of an interconnected power system operating in island mode. Island mode refers to a system that operates independently from the utility grid. If the EVSE or WPTE is considered interactive equipment, it is also acceptable for energy to be backfed from the EV to the wiring system on the premises. If the EVSE or WPTE is not considered interactive equipment, there must be restrictions put in place so that when power is lost, energy cannot be backfed. If the interactive equipment is part of an optional standby system, then Article 702: Optional Standby Systems requirements apply. If the interactive equipment is part of an electric power production source, then Article 705: Interconnected Electric Power Production Sources requirements apply.

Article 750: Energy Management Systems is important for designing EVSE or WPTE that are a part of an energy management system (EMS). If the energy management system is being used to limit current on conductors, the maximum equipment load on a service and feeder can be the maximum load permitted by the EMS. It is also possible that the EMS is integral to the EVSE. If that is the case, the EVSE must be marked to indicate that this EMS control is being provided within. Similarly, the EVSE can have adjustable settings that impact the rating of the equipment. If that is the case, then the change to the rating must be per the manufacturer’s instructions, and the adjusted rating must appear on the rating label.

Because components of the electrical distribution system are able to be altered with an EMS in place, it is also required that the EMS cease current flow upon malfunction. This helps to protect any branch circuit, feeder or service from being overloaded. The adjustable settings also must be in a secure location or password-protected so they can only be altered by facility personnel.

In addition to Articles 400, 625 and 750 of the NEC, here are some listings and standards related to EV charging stations to be aware of:

- NECA 413: Installing and Maintaining Electric Vehicle Supply Equipment for information on the procedures for installing and maintaining AC Level 1, AC Level 2 and fast-charging DC EVSE.

- NFPA 69: Standard on Explosion Prevention Systems for combustible gas concentration restrictions for EV charging batteries.

- NFPA 505: Fire Safety Standard for Power Industrial Trucks Including Type Designations, Areas of Use, Conversions, Maintenance and Operations for information on fire protection of industrial trucks.

- SAEJ1772: Standard for Electric Vehicle and Plug in Hybrid Electric Vehicle Conductive Charge Coupler for further requirements on the physical, electrical, functional and performance of conductive charging of electric vehicles.

- SAEJ3072: Standard for Interconnection Requirements for Onboard, Utility-Interactive Inverter Systems for further information on the grid support inverter system integral to the electric vehicle.

- UL 1741: Inverters, Converters, Controllers and Interconnection System Equipment for Use With Distributed Energy Resources for further information on supply equipment.

- UL 2202: Electric Vehicle Charging System Equipment for information on conductive electric vehicle charging equipment.

- UL 2594: Electric Vehicle Supply Equipment for information on conductive electric vehicle supply equipment.

- UL 9741: Bidirectional Electric Vehicle Charging System Equipment for vehicle interactive systems.

EV charging station levels

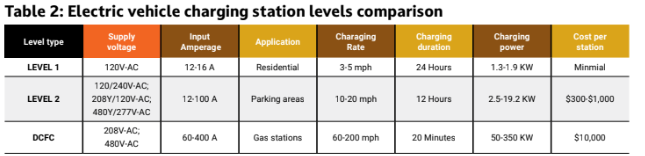

There are different levels to classify the supply voltage type when it comes to EV charging stations. Level 1 charging has a supply voltage of 120 V-AC, single phase, and can have an input amperage between 12 to 16 amperes. Level 1 charging is more common in residential applications as it utilizes a grounded 120-volt receptacle and is often portable. It is typical that the Level 1 chargers are provided by the EV manufacturer with purchase. Level 1 charging will charge a vehicle anywhere between three to five miles per hour, taking about a day to fully charge. The Level 1 EVSE usually has a charging power of 1.3 to 1.9 kilowatts.

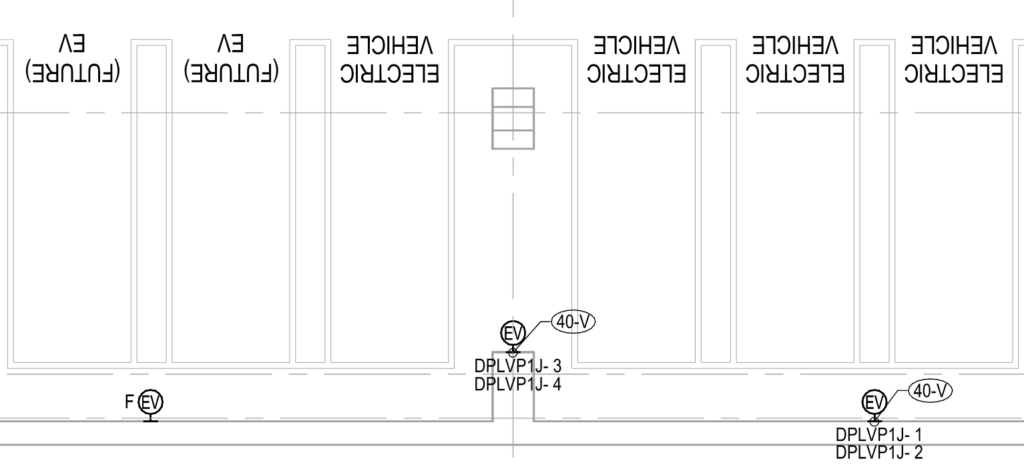

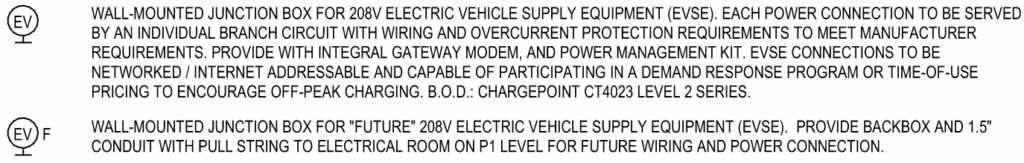

Level 2 charging can have a supply voltage of 120/240V-AC, 208Y/120V-AC and 480Y/277V-AC. It can have an input amperage between 12 to 100 amperes, with the average being 40 amperes. Level 2 charging is more common in commercial applications (i.e., parking lots and parking garages) and is often fastened-in-place or fixed-in-place. It will charge a vehicle anywhere between 10-20 miles per hour, taking about half a day to fully charge. The Level 2 EVSE usually has a charging power of 2.5 to 19.2 kilowatts. With commercial applications, it’s not uncommon to have several EVSE installed on the premises. Therefore, in design, there is typically an electrical panelboard that is dedicated to the EVSE, and each EVSE has a dedicated circuit with its own overcurrent protection.

Level 3 charging, which is now known more commonly as DC fast charging (DCFC), can have a supply voltage of 208V-AC or 480V-AC three-phase. It can have an input amperage between 60 to 400 amperes, demanding the most electricity out of the three levels, with the higher ampere value ever-growing. DCFC stations are typically seen in public open spaces like gas stations and are fixed in place. These stations will charge an EV anywhere between 60 to 200 miles per hour, taking about 20 minutes to fully charge. As the input amperage grows in value, this 20-minute timespan will continue to reduce. The DCFC EVSE usually has a charging power of 50 to 350 kilowatts.

Table 2 summarizes the information mentioned above, as well as the average cost of each of these charging stations.

Design Coordination for EVSE

As an electrical engineer, it is important to coordinate with several other disciplines when designing EV charging stations. Other disciplines include: civil engineering, fire protection engineering, information technology, landscape architecture, mechanical engineering and structural engineering.

With a civil engineer or landscape architect responsible for parking spaces, programming and signage, it is crucial to coordinate the quantity and location of EV parking spaces. The requirements depend on where the EV design is occurring, as well as the sustainable initiatives the client is interested in pursuing. For example, in Ann Arbor, Mich., the city requires at least 10% of parking spaces in a parking lot to have EVSE installed. To receive the Green Vehicles Credit, LEED BD+C requires at least 5% of all parking spaces utilized by a project to be preferred parking for green vehicles. Additionally, with the Americans with Disabilities Act and the Architectural Barriers Act, there are requirements regarding the accessibility of EV charging stations in design and construction. If the project design incorporates on-grade parking lots, the civil engineer must know where these designated EV parking spaces are located to ensure there are no conflicts with other underground utilities.

When the EV charging stations are located within a structure like a parking garage, the fire protection engineer must be notified of the EVSE location and quantity to make sure the structure complies with NFPA 13: Standard for the Installation of Sprinkler Systems.

It is common for Level 2 and Level 3 EVSE to utilize cellular connectivity for features such as billing, energy usage reporting and charging status. As a result, the information technology designer must be informed of the physical location of the EV charging stations to ensure that cellular connection is possible in the proposed design location.

Coinciding with the NEC Article 625.52: Ventilation, if the EVSE is not listed for charging EVs indoors, ventilation is required, and a mechanical engineer must be notified. The NEC indicates that both supply and exhaust equipment must be provided, permanently installed and located where intake and exhaust are both directly adjacent to the outdoors

Lastly, like how an electrical engineer coordinates the physical weight of electrical equipment, if the EVSE is fixed-in-place, or fastened-in-place and mounted to a wall or floor surface, the weights of the EVSE need to be coordinated with the structural engineer.