Successful decarbonization efforts begin with an eye toward energy efficiency.

Learning objectives

- Identify which codes and standards set energy efficiency and performance requirements.

- Understand how improved equipment efficiency reduces emissions and operational costs.

- Review how improved efficiency enables the use of low carbon heating and cooling methods.

Decarbonization insights

- Energy efficiency is a critical component of decarbonization efforts, as it reduces heating and cooling loads, minimizes system sizes and supports the transition to fully electric systems like heat pumps.

- By enforcing building energy codes, optimizing equipment performance and improving building envelopes, engineers and designers can significantly lower carbon emissions and energy use across both new and existing structures.

By enforcing building energy codes, optimizing equipment performance and improving building envelopes, engineers and designers can significantly lower carbon emissions and energy use across both new and existing structures.According to the United Nations Environment Programme, in 2022, buildings were responsible for 37% of energy and process-related carbon dioxide (CO2) emissions globally. To help reduce the impact these buildings and the built environment have on global warming and climate change, an effort defined as decarbonization or the reduction of carbon emission needs to take place.

Energy efficiency is a critical component of decarbonization efforts, as it reduces heating and cooling loads, minimizes system sizes and supports the transition to fully electric systems like heat pumps.

Decarbonization, however, should not be an isolated undertaking. For example, switching from fossil fuel sources to clean energy electrical sources could have a disastrous effect on electrical power and distribution systems that are ill-equipped to handle new and expanded load requirement. It is for this reason that careful and coordinated efforts are required and why energy efficiency becomes a key factor.

A fundamental step toward decarbonization is to incorporate and enable practical energy efficiency measures. According to ASHRAE, buildings account for approximately 40% of CO2 emissions associated with energy. Reducing heating and cooling loads by implementing energy efficiency measures goes together with replacement or modification of heating and cooling equipment, thereby furthering decarbonization goals.

Table 1: IECC code adoption by state per the International Code Council

| Alabama | 2021 | Louisiana | 2009 | Oklahoma | 2009 |

| Alaska | 2021 | Maine | 2021 | Oregon | 2018 |

| Arizona | 2012 | Maryland | 2021 | Pennsylvania | 2018 |

| Arkansas | 2009 | Massachusetts | 2018 | Rhode Island | 2018 |

| California | No Statewide Adoption | Michigan | 2015 | South Carolina | 2015 |

| Colorado | 2021 | Minnesota | 2018 | South Dakota | 2015 |

| Connecticut | 2021 | Mississippi | 2018 | Tennessee | 2018 |

| Delaware | 2021 | Missouri | Local Adoptions | Texas | 2015 |

| District of Columbia | 2021 | Montana | 2021 | Utah | 2018 |

| Florida | 2021 | Nebraska | 2018 | Vermont | 2018 |

| Georgia | 2015 | Nevada | 2021 | Virginia | 2021 |

| Hawaii | 2015 | New Hampshire | 2018 | Washington | 2018 |

| Idaho | 2018 | New Jersey | 2018 | West Virginia | 2015 |

| Illinois | 2021 | New Mexico | 2018 | Wisconsin | 2015 |

| Indiana | No Statewide Adoption | New York | 2018 | Wyoming | 2018 |

| Iowa | Local Adoptions | North Carolina | 2015 | ||

| Kansas | 2018 | North Dakota | 2021 | ||

| Kentucky | Local Adoptions | Ohio | 2018 |

Table 1: Most states have adopted a version of the International Energy Conservation Code (IECC), others have developed their own. This table outlines the version of IECC adopted by each state according to the International Code Council. Courtesy: CDM Smith

For example, enhancing a building’s thermal envelope would likely allow for a decrease in the size of the heating, ventilating and air conditioning (HVAC) systems serving it. When converting from a conventional fossil-fueled heating system to a heat pump system driven by electricity, it is critical to incorporate energy efficiency measures to thereby reduce system sizes and associated infrastructure and to enable installation. Such incorporation can have the positive benefit of reduced installation costs, smaller wire sizes and an associated smaller electrical service (as opposed to a scenario in which measures were not implemented).

As noted by the American Council for an Energy-Efficient Economy, 26 states and the District of Columbia contribute to 82% of the total energy savings within the country. These savings are made possible through Energy Efficiency Resource Standards (EERS) and legislation that strives for increased decarbonization and a cleaner environment. Reportedly, EERS states contain approximately 59% of the United States population but account for 82% of the energy savings across the country.

Energy efficiency is often regulated through the provision of building energy codes, which set efficiency and performance requirements for new buildings, renovations of existing buildings and other various items (heating equipment, cooling equipment, insulation, etc.). While most states have adopted a version of the International Energy Conservation Code (IECC), others have developed their own (see Table 1).

Existing building efficiency, decarbonization measures

Several programs and resources are available to support improvements in existing building stock. Administered by the U.S. Environmental Protection Agency, Energy Star provides information to help protect the environment, improve air quality and protect public health. Engineers, owners and building operators are encouraged to review the implementable energy conservation measures that relate to operations and maintenance, lighting, plug loads, heating and cooling and occupant behavior and education.

Additionally, through its Energy Star Portfolio Manager and Target Finder offerings, designers, architects and engineers can not only benchmark the energy performance of their existing building stock, but also identify the anticipated performance and efficiency of buildings that are currently in the design process, allowing informed design decisions to be made along the way.

Engineers reference existing standards to incorporate building efficiency measures in their designs. ASHRAE Standard 90.1: Energy Standard for Buildings Except Low-Rise Residential Buildings standard specifies the minimum requirements for energy efficiency when designing and constructing commercial buildings.

Building envelope: Heat transfer occurs because of the difference between the ambient outdoor temperature and indoor temperature of the building. The magnitude of this heat transfer determines the total heating load and cooling load required to maintain the desired temperature within the space. Several building characteristics affect these loads, including building size, building age, building envelope, infiltration loads, internal loads, ventilation loads and humidification loads.

The building envelope includes windows, doors, walls and the roof; each component has an associated U-factor — a heat transfer characteristic that is dependent on the type of construction material. ASHRAE 90.1 outlines requirements in Chapter 5, Building Envelope, and the IECC outlines thermal envelope minimal requirements based on climate zones, as listed in Section C402, Building Envelope Requirements.

Thermal envelope minimum requirements apply to new buildings, additions to existing buildings and (in some cases) alterations to existing building envelopes. These requirements vary by climate zone and represent minimum standards to which buildings must be constructed and the baseline against which any improvements above the minimum are measured. Building designers and owners use these factors to quantify the effectiveness of improving thermal envelope performance and thereby determine which measures to pursue.

Improving a building’s thermal envelope reduces its cooling, heating and subsequently energy loads. Efficient thermal envelopes lessen infiltration loads and reduce heat transfer between the ambient conditions and space conditions inside the building.

These improvements have a more prominent effect on a building’s heating loads versus the cooling loads, especially in colder climates where the outdoor air temperature is much colder than the space temperature setpoints of the building. This is because heat transferred through a wall or roof varies linearly with both the temperature gradient across the assembly and the R-value of the assembly. Where the temperature gradient between indoor and outdoor temperature is large, for example a building maintained at 68°F on a 10°F day, increasing the R-value of the insulation used reduces the energy transfer a larger amount (although in the same proportion) as the same insulation would on a 95°F day where the indoor temperature is maintained at 72°F.

In the same manner, reducing infiltration volume has a proportionally greater impact on loads when the temperature difference between the infiltrating and conditioned air is larger, due to the need to affect a larger temperature change on the infiltrating air.

Equipment performance: Some implementable efficiency measures related to equipment performance include installation of air and water side economizers, variable speed drives for pumps and fans and ventilation air energy recovery. Minimum requirements for these measures can be found in ASHRAE 90.1 Chapter 6, Heating, Ventilating and Air Conditioning. The IECC outlines the requirements for installing air and water economizers (Section C403.5, Economizers).

Air-side economizers save energy by taking advantage of cooler outdoor conditions and supplying the cool outdoor air instead of using a mechanical cooling system to condition the air. ASHRAE 90.1 outlines when an air-side economizer should turn on, based on the control type and climate zone where the building is located.

Water-side economizers also take advantage of cool ambient conditions to reduce the energy required by a hydronic cooling system, such as a chiller. When outdoor air temperatures are cool enough, a cooling tower can exchange heat between the outdoor air and the cooling system fluid to cool or pre-cool the fluid. Though some energy is required to distribute the fluid and to operate the cooling tower, significant energy savings result from pre-cooling the fluid as opposed to operating a chiller for a few hours.

Air-side economizers tend to be more effective in reducing energy demands, as there are fewer heat exchanger interfaces at which energy is lost than water side economizers, however humidity control is limited and a direct duct connection of sufficient size from the conditioned space to the outside is required. While water-side economizers lose some effectiveness as energy passes through a hydronic system, they allow better humidity control and can be used in spaces without a ducted connection to outdoor air.

An energy recovery ventilator (ERV) exchanges heat with leaving exhaust air for the purpose of preheating or precooling supply air in the air handling unit (AHU). ERVs are designed to exchange heat between the air streams via internal heat exchangers, energy wheels and other methods. ERVs that allow for moisture transfer in addition to heat transfer additionally allow for the transfer of latent energy, reducing humidification loads. Harnessing this heat reduces the requirement size for the heating coil and, consequently, also reduces the amount of energy consumed to operate the unit (as compared to a typical AHU). The IECC outlines the requirements for installing energy recovery for ventilation systems (Section C403.7.4, Energy Recovery Systems).

Equipment conversions: Common decarbonization measures are converting existing fossil fuel buildings into heat pumps (either air-source or water-source) and designing new construction to include heat pumps, as heat pumps are a fully electric technology, thus eliminating on-site burning of fossil fuels.

ASHRAE Standard 90.1 outlines the minimum efficiency requirements and test procedures for heat pumps and other equipment in Chapter 6.8, Minimum Equipment Efficiency Tables. The IECC references ASHRAE 90.1 within C403.3.2, HVAC Equipment Performance Requirements, which also outlines the minimum efficiency requirements and test procedures of heat pumps and other building mechanical system equipment.

These requirements specify the minimum standard all designs must meet and they allow for a direct comparison between different system types and a quantification of energy and carbon savings associated with installing high-efficiency equipment or fully electric systems. By quantifying these savings above a minimum required system efficiency or against a baseline alternate system type, designers and owners can make informed decisions about how to most effectively use available resources to meet decarbonization goals.

Among heat pump systems, air-source heat pumps tend to have lower capital costs and installation complexity than water-source heat pumps because they require less equipment and distribution infrastructure.

However, water-source geothermal heat pump systems tend to use less energy than air‑source heat pumps and, therefore, have lower operational costs. Both technologies are highly efficient compared to traditional HVAC equipment. The higher efficiencies reduce energy consumption by as much as 70% to 80%, according to the Department of Energy.

Standards for air-source heat pump testing and rating for performance are outlined in AHRI Standard 210/240: Performance Rating of Unitary Air-Conditioning and Air-Source Heat Pump Equipment, AHRI Standard 340/360: Performance Rating of Commercial and Industrial Unitary Air-Conditioning and Heat Pump Equipment, and AHRI Standard 1230: Performance Rating of Variable Refrigerant Flow (VRF) Multi-Split Air-Conditioning and Heat Pump Equipment.

Typically, ground-source heat pumps are slightly more efficient than air-source heat pumps, especially in colder climates where air temperatures drop significantly in the winter. The coefficient of performance (COP) — a measurement of energy input compared to the output of energy — can depend on the type of heat pump and performance metrics, such as entering air/water temperature. Standards for ground-source heat pump testing and rating for performance are outlined in ANSI/AHRI/ASHRAE/ISO Standard 13256-1: Water-to-Air and Brine-to-Air Heat Pumps, and ANSI/AHRI/ASHRAE/ISO Standard 13256-2: Water-to-Water and Brine-to-Water Heat Pumps.

Ground-source heat pumps transfer heat between a geothermal (ground) source loop to the heat pump refrigerant to provide heating and cooling to a space. Typically, the geothermal source temperature will vary between a minimum of 30°F to 40°F and a maximum of 80°F to 90°F throughout the year, although these temperatures can vary based on system design choices, including size of borefield and acceptable condenser water inlet ranges for heat pumps.

Air‑source heat pumps transfer heat between the outdoor ambient air temperature to the heat pump refrigerant to provide heating and cooling to a space. Depending on where the heat pump is located, the outdoor air temperature could vary significantly. There are several studies investigating the effect of extreme temperatures on air-source heat pump performance, including organizations such as the New York State Energy Research and Development Authority.

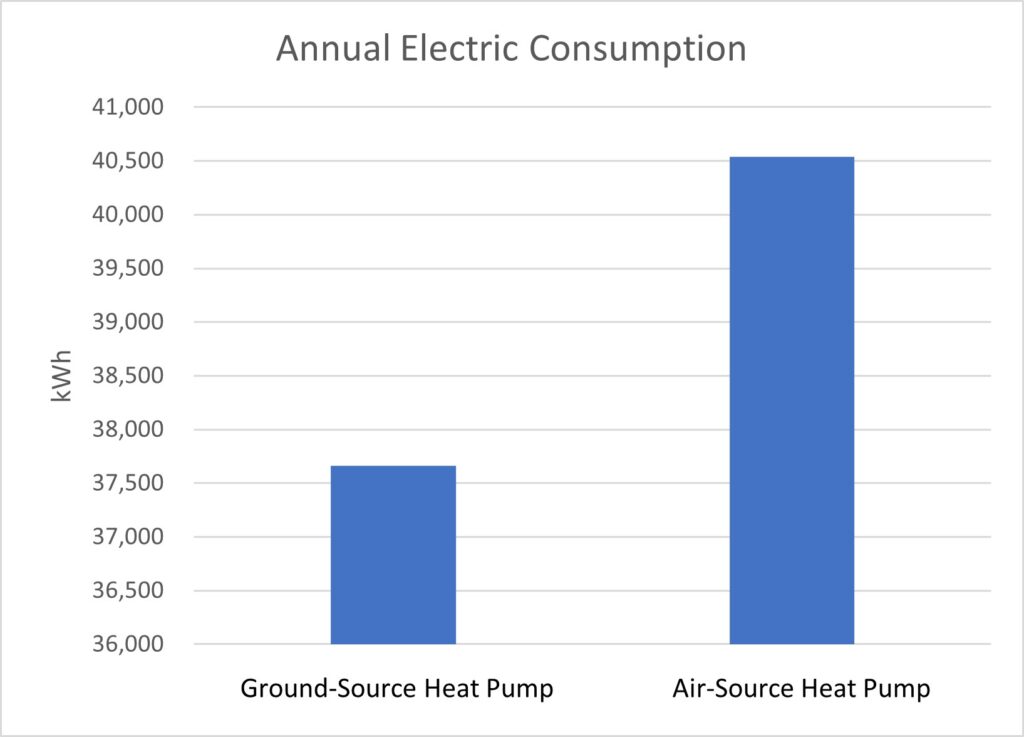

When comparing the life cycle cost analysis of ground-source heat pumps to air-source heat pumps for multiple building types in New York City (NYC), the annual electric consumption for ground-source heat pumps is less than an air-source heat pump (owing to the differences in efficiency, see Figure 2).

For a 1,300-square-foot commercial building in NYC, a geothermal heat pump consumes approximately 37,500 kilowatt-hours (kWh) of electricity throughout the entire year. In comparison, an equivalent air-source heat pump consumes approximately 40,500 kWh of electricity throughout the entire year (owing to the difference in COP), a 7.7% difference between the ground source heat pump and the air-source heat pump.

Guidelines to achieve energy efficiency and decarbonization

U.S. Green Building Council’s LEED has been established for more than 20 years. LEED building rating system outlines requirements for efficient and sustainable building performance. Several decarbonization and building electrification laws were recently passed to curb emissions — buildings in NYC are responsible for more than two-thirds of the city’s greenhouse gas emissions.

Approved in December 2021, Local Law 154 mandates that new construction cannot emit more than 25 kilograms of carbon dioxide per million British thermal units (kg CO2/MMBtu) from on-site combustion of fuels. Local Law 97 was enacted in 2019 and aims to reduce greenhouse gas (GHG) emissions from buildings by requiring compliance in 2024 and setting stricter GHG emission limits to go into effect in 2030m according to the NYC Department of Buildings.

To comply with Local Law 97 and 154, some new buildings in NYC have been designed using the Passive House standard. The Passive House Institute and Passive House Institute U.S. developed the Passive House standard for building performance. To meet the standard, buildings must achieve a 90% reduction of energy needs for heating and cooling and a 75% reduction of overall energy use compared to existing buildings.

To achieve these requirements, the building design focuses on the thermal envelope, heat recovery ventilation and solar and internal heat gains. Like all heating and cooling load reduction measures, building to this standard can facilitate electrification by reducing equipment sizes and the resulting grid impact from shifting heating from gas to electric power.

Modeling efficient building energy systems

By reducing building energy consumption through efficiency measures, new clean energy technologies can be enabled to meet building and facility needs. Designers and engineers will need to make a series of decisions that will not only drive the design process but will impact the future operations and maintenance of the building.

Exploring energy efficiency options, for both the building envelope and the system equipment, requires that the design approach be shifted regarding energy modeling. A load model focuses on determining the peak heating and cooling loads for an HVAC system whereas an energy model focuses on the annual energy usage of the building. The equipment selections are based on meeting those peak loads while offering a comfortable margin of safety.

In contrast, an approach focused on overall efficiency and decarbonization must account for the actual performance of a building over a full year of system operation and the full lifetime of the equipment. Accurately modeling the designed building envelope, equipment efficiencies and control schemes prevents oversizing systems and optimizes system operational efficiency.

Energy models produced for the design of geothermal systems must output “8760 models” that accurately reflect system loads to provide an hour-by-hour analysis for all 8,760 hours in a year to thereby evaluate the balance between heat pulled from and rejected to the ground. The balance of annual heating and cooling loads determines the required ground heat exchanger capacity and any additional balancing equipment, which are reflected by the building performance throughout the year. The goal is to produce accurate energy models that capture the actual building energy performance. The energy model must consider how residents maintain their spaces.

The IECC requires a minimum space temperature setpoint of 75°F for cooling and maximum space temperature setpoint of 72°F for heating, but these temperatures may not always be followed by the building tenants. On a really hot day, tenants may bypass the thermostat to decrease the space temperature to 68°F or 70°F. On cold days, some tenants may be more frugal and keep the space temperature lower, whereas other tenants, such as senior residents, could keep the space temperature higher to maintain comfort.

To ensure energy models are accurate for existing buildings, the energy models should be calibrated based on real data from existing customers, such as historical natural gas and electricity utility bills; however, utility bills would not be available for new buildings. The building’s use should be well understood and incorporated into the building energy model through occupancy schedules and equipment schedules. If the building schedule is unknown, typical schedules are available in ASHRAE 90.1.

Domestic hot water loads can also be served via a geothermal ground heat exchanger and water-source heat pump equipment that produce domestic hot water and should be included in the energy model. Once the domestic hot water usage is determined, the hourly load profile can be built out. ASHRAE provides typical domestic hot water hourly load profile graphs in Chapter 51, Service Water Heating, in the “2023 HVAC Applications Handbook.” These graphs provide average, peak and 95% confidence interval data for multiple building types. When modeling domestic hot water loads, ascertain how the building operates and choose the correct domestic hot water profile.

Electrification of heating and cooling systems reduces a building’s energy usage in the short term and can have a greater impact on overall decarbonization as power generation becomes more efficient and renewable technologies are implemented. Improvements to the carbon efficiency of fossil-fuel-based systems are subject to diminishing returns that are limited by the energy content of the fuel, while fully electric systems can be as emissions-free as the source of electric energy and register as a fully net-zero system. Energy efficiency improvements in building envelope and equipment designs can be combined with efficiency improvements in power generation to create a holistic approach to decarbonization.