The demand for electric vehicles is increasing, so the demand for charging is also on the rise. If charging is to become more widely available, it must be integrated into our infrastructure in a meaningful way.

learning objectives:

- Understand common grid concerns involved with EV charging.

- Learn the basic EV charging design considerations.

- Identify different types of projects that can integrate EV charging.

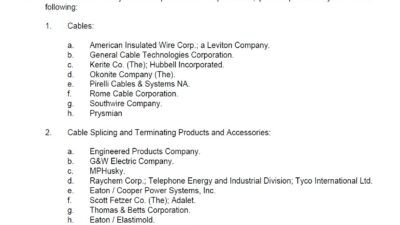

Electric vehicle supply equipment (EVSE) design requirements are defined by NFPA 70: National Electrical Code (NEC). In addition to the NFPA standards, there are a significant number of codes, standards and guides that govern or assist in the design of EVSE, including:

- American National Standards Institute

- International Building Code

- International Fire Code

- International Mechanical Code

- Institute of Electrical and Electronics Engineers

- National Electrical Manufacturers Association

- NFPA 1: Fire Code

- Occupational Safety and Health Administration

- SAE International

- Unified Facilities Criteria

- UL Solutions

- Local codes and owner’s design guidelines

With electric vehicles (EVs) rapidly changing their technology every year, standards developing organizations are still reacting to technological developments created by vehicle manufacturers.

The 2023 edition of the NEC defines EVSE in Article 100 as:

“Equipment for plug-in charging, including the ungrounded, grounded and equipment grounding conductors and the electric vehicle connectors, attachment plugs, personnel protection system and all other fittings, devices, power outlets or apparatus installed specifically for the purpose of transferring energy between the premises wiring and the electric vehicle.”

The 2023 edition of the NEC defines an EV connector in Article 100 as:

“A device that, when electrically coupled (conductive or inductive) to an electric vehicle inlet, establishes an electrical connection to the electric vehicle for the purpose of power transfer and information exchange.”

The United States National Highway System is established and expansive. An integral part of this system is the fuel stations located every few miles along every major highway. As the world slowly but inevitably transitions to an EV future, the existing highway infrastructure system will need to be upgraded and/or converted to accommodate charging for millions of vehicles.

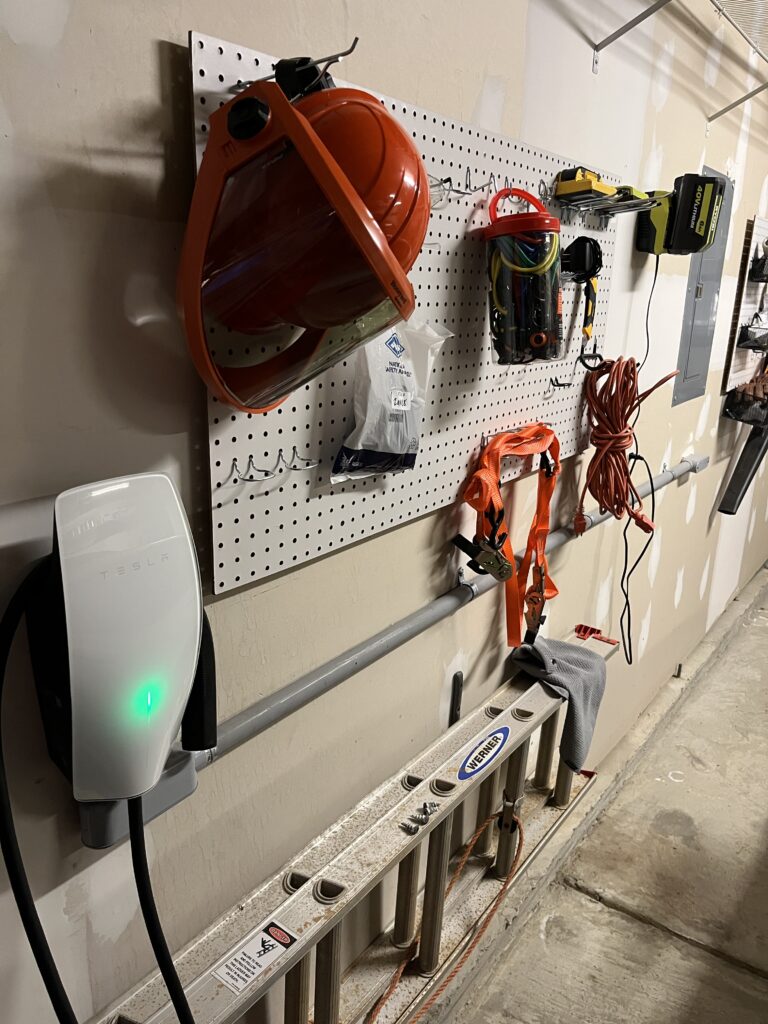

A new, convenient aspect of EVs is the relative ease with which a user can charge at home. However, the vast majority of existing and even new homes do not have EV chargers installed. Yet, their installation is trending sharply upwards.

As we look at the scenarios: home, around-home and highway, we have to understand what it takes to bring EV chargers to millions of users. This includes safety and rules of best practice for installing, maintaining and operating electric vehicle chargers.

EV charger types

As EV technology continues to develop and become more standardized, so does EVSE technology; recent advancements in EVSE include dynamic wireless charging, stationary wireless charging and bidirectional charging. Care should be given in applying these advancing technologies, as different EVSE technologies have different maturities in different markets. For instance, while bidirectional charging may be readily available for residential installations, it may lag for commercial or industrial installations. As these technologies mature, the requirements and recommendations from codes, utilities and other concerned groups must also mature.

Dynamic wireless charging uses magnetic fields produced by inductive charging coils embedded in roads to induce voltage in an aftermarket-installed receiver to charge EVs while they are in motion. In November 2023, the Michigan Department of Transportation announced the installation of inductive charging coils in a quarter-mile segment of 14th Street in Detroit, making it the first public street in the United States to be equipped with dynamic wireless charging. Other states, such as Florida and Indiana, have similar projects planned. The widespread installation of dynamic wireless charging can help alleviate range anxiety and reduce the need for frequent stops by charging EVs while they are in motion.

Stationary wireless charging uses wireless charging pads and an aftermarket-installed receiver to charge EVs while they are parked. These chargers are not yet widely available to the public; however, companies such as Plugless Power and WiTricity offer stationary wireless charging options for purchase. Stationary wireless charging offers increased convenience and reduced wear and tear by eliminating the need for physical connectors and handling of cables.

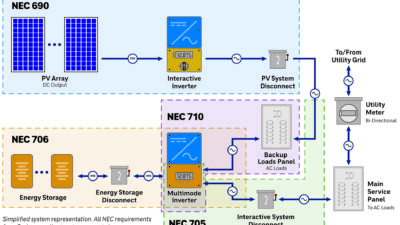

Bidirectional charging is a two-way power system that allows power to flow to and from the battery of EVs. There are four main bidirectional charging configurations:

- Vehicle-to-grid (V2G): Can improve grid stability by using bidirectional charging.

- Vehicle-to-home: Places the EV in a backup power role, almost like a standby generator.

- Vehicle-to-load: The most available technology in the current EV market, because it can power a 120-volt load with the vehicle.

- Vehicle-to-vehicle (V2V): Much safer alternative than siphoning gas from one vehicle to use it in another.

The technology, standardization and implementation strategies of bidirectional charging are still being developed by many manufacturers. For many manufacturers, bidirectional charging is expected to become a widely available, standard feature for EVs as soon as 2026. Despite this push to make bidirectional charging widely available, significant issues with regulatory bodies and utility companies are still expected to impact the implementation of V2G and V2V bidirectional charging by manufacturers and utilities.

Regarding traditional plug-in charging stations, consistent advancements in EVSE include faster charging speeds and more energy-efficient smart charging systems. The current levels of EV charging include Level 1, Level 2 and Level 3, or direct current fast charging (DCFC) chargers, each of which varies in power input and output, charge time and availability.

Level 1 chargers are the slowest and can take more than 50 hours to fully charge an EV from empty. These chargers use a standard three-prong NEMA connector (e.g., NEMA 5-15, NEMA 5-20) to plug into a standard receptacle for power. Level 1 chargers typically use a 15- or 20-ampere (A), 120-V alternating current (AC) branch circuit, and have a typical power output of 1 to 2 kilowatts (kW). Because Level 1 chargers are slow, they are typically only used for charging at home and are not recommended for charging EVs while traveling long distances or completing tasks that require long runtimes. Since the last quarter of 2019, public Level 1 chargers have been decommissioned more than they have been installed for public use.

Level 2 chargers are the most common public charging port. There are more than 180,000 Level 2 charging ports, making up approximately 74.5% of the total number of public charging ports in the U.S. and Canada. Level 2 chargers require a 208 V to 240 V AC input voltage and have a typical power output of 7 to 19 kW. Level 2 chargers provide improved charge times compared to Level 1 chargers, with an estimated full charge from empty within 4 to 10 hours. Level 2 chargers are significantly cheaper than Level 3 chargers, with costs ranging from $300 and $1,000. Because Level 2 chargers have a faster charge time and most homes have 240 V AC service available, Level 2 chargers are commonly installed for at-home charging in place of Level 1 chargers. As EV adoption widens, public charging infrastructure for Level 2 and Level 3 chargers will become more important, especially in dense urban environments where street parking is common.

Level 3 chargers, also known as DCFC chargers, are the fastest chargers and are estimated to fully charge an empty EV within 20 minutes to 1 hour. These chargers typically require a three-phase, 480 V AC or 208 V AC input voltage that is then converted to 200 to 1,000 V direct current. Typical EV battery system architectures are 400 V or 800 V, with 400V being the most common. Additionally, Level 3 chargers have a power output of up to 350 kW. Level 3 chargers are also the fastest growing public charging ports.

Connector types

SAE is a standards developing organization that contributes to the automotive, aerospace and other mobility industries. SAE has made significant contributions to the development and advancement of standards for EV charging infrastructure, including standards for the two most common EV connectors—SAE J1772 and SAE J3400.

The SAE J1772 is an AC charging connector and is one of the most common connectors for Level 1 and Level 2 chargers. SAE International first published the SAE J1772 standard in 2001 and has updated it, as needed, to reflect technological advancements in the EV charging industry. Most automobile manufacturers, with the main exception being Tesla, use the SAE J1772 connector for their Level 1 and Level 2 charging systems.

The North American Charging Standard (NACS), also referred to as the SAE J3400, is an AC and DC charging connector that can be used with Level 1, Level 2 and Level 3 chargers. The NACS was developed by Tesla and was first deployed for use in 2012. Tesla later published the design and specifications for other automobile manufacturers and EV charging infrastructure providers to use as well. In 2024, SAE International fully endorsed the NACS and standardized it as the SAE J3400. Automobile manufacturers like General Motors, Ford and Mercedes-Benz have begun either adopting the NACS charging port for newer EV models or offering a NACS adapter for older EV models. Other automobile manufacturers like Toyota, Volkswagen and Honda have yet to adopt NACS charging ports or adapters, but have committed to adopting the NACS in some capacity starting in mid- to late-2025. Adopting the NACS charging port allows non-Tesla EVs to use the Tesla charging network, which is often regarded as the most reliable EV charging network.

The combined charging system combo 1 (CCS1) is an AC and DC charging connector (similar to the NACS) that can be used with Level 1, Level 2 and Level 3 chargers. The CCS1 combines the SAE J1772 with two additional pins for DC fast charging. Because the CCS1 can facilitate DC fast charging, CCS1 connectors are typically used with Level 3 chargers. Like the SAE J1772, most automobile manufacturers (except for Tesla) use the CCS1.

The CHAdeMO is a DC charging connector used for Level 3 charging. The CHAdeMO was developed before the CCS1 and is primarily used by Japanese automobile manufacturers. However, with the inception of the CCS1 and the adoption of NACS, CHAdeMO is becoming obsolete in North America.

The megawatt charging system (MCS) SAE J3271 is an emerging charging standard under development for a charging connector and charging station that is capable of having a power output of 440 kW (non-cooled) to 3.75 Megawatts (cooled). MCS SAE J3271 will primarily be used for charging medium- and heavy-duty commercial vehicles. MCS SAE J3271 is expected to reach the industry standard design phase as soon as 2025 or 2026.

EV manufacturers and charging network companies that are currently leading the charging industry include Tesla, ChargePoint, EVgo and Electrify America. Except for Tesla, most of these companies install charging stations with multiple common connector types.

Design considerations

Designing EV charging infrastructure requires planning to ensure accessibility, reliability and future scalability. Key factors include site selection, power availability, charger type, user needs and grid impact.

EV charging can significantly affect local electric grids. High concentrations of charging during peak demand hours can cause blackouts, brownouts and overloading. Utilities are adapting to the increase in charging by upgrading their equipment. However, by using smart charging and load management, utilities and municipalities can better distribute demand and even use EVs as flexible energy resources with bidirectional charging. For this reason, many large-scale charging projects involving Level 3 or Level 2 chargers may require coordination with the local utility.

A smart charging system uses communication between an EV, a charging device and a user to adjust charging based on the state of the grid, electricity rates and user preferences. By shifting charging from peak hours to off-peak hours, smart charging can help prevent overloading the grid and reduce the risk of blackouts and brownouts. Scheduling charging to occur during off-peak hours has financial benefits, too. Many utilities offer time-of-use rates where electricity rates are lower during off-peak hours. By utilizing time-of-use rates, the user and utilities can both save money. Users may also opt to define their own charging profiles to better suit their lifestyle.

To further stabilize the grid while it experiences the growth in EV charging, renewable energy sources and battery energy storage systems (BESS) can be utilized to offset peak demands and allow the grid to become more resilient to blackouts and brownouts. Smart charging systems can be implemented to ensure EV charging occurs during periods when renewable energy production is at its highest, thus reducing the strain and reliance on the grid. BESS can be strategically charged when time-of-use rates are lower (during off-peak hours) and can be discharged to power the charging stations to help offset peak demands and reduce power costs.

Multiple types of EV chargers can also be networked together using integral software to allow the system owner to monitor and control charging events. This allows all chargers to communicate with each other while also allowing the owner to schedule charge time or control the charging demand. Demand load management helps to ensure that the electrical capacity of the system is not exceeded during any type of outage event. Open Charge Point Protocol (OCPP) is a commonly used communication standard. OCPP utilizes web sockets or secure web sockets to establish secure, real-time, two-way communication between EV charging stations and a central smart charging management system. Once connected, OCPP can be used to remotely start, stop, and adjust charging sessions, report faults and malfunctions, monitor energy consumption and other operational parameters, facilitate smart charging capabilities such as load balancing and integration with renewable energy, and more.

EV charging stations are typically placed in highly trafficked areas, such as parking garages, shopping centers and grocery stores. As a result, charging stations are susceptible to accidental and intentional damage, such as collision, theft and vandalism. To best protect the EV charging stations from damage caused by a collision, physical barriers such as bollards and guards should be installed.

To help deter theft and vandalism, a surveillance system should be installed. While surveillance system will not guarantee protection against theft and vandalism, it will capture any incidents that occur. Another deterrent to theft and vandalism, especially at night, is ensuring the charging station area is well-lit. A well-lit area will offer better visibility and increase the likelihood for police, surveillance systems and other security personnel to see the crime occur and then put a stop to it. In addition, a well-lit area increases safety by allowing users to identify potential hazards such as water or ice.

Scenarios

When listing the pros and cons of EV charging, charging times and range anxiety are often rated as a negative. However, EV charging does not have to be an inconvenience—the ability to charge at destinations and at home is a major positive. As battery technology improves, owners will spend less time waiting for their car to charge. And, if there is a charger at both home and the destination, then “stopping just to charge” may no longer be an obstacle.

This convenience is the long-term result of EV chargers in parking garages. Many existing parking decks/garages have been retrofitted with a few EV chargers to serve. However, as the production and demand for EVs increase, new construction designs for parking decks/garages must consider the integration of chargers. A recent project in Massachusetts constructed a 300-spot parking deck beneath a sports facility; it included more than 25 EV charging stations with an electrical system ready to support 78 future chargers. The system includes demand load controls to manage the chargers’ electrical demand when many or all chargers are in use. This investment in future infrastructure is not only required to make charging more convenient, but it will also make charging more accessible in dense urban areas and reduce the need for dedicated refueling stations. A spectator at a sports event can drive to the field, plug in to a Level 2 charger, and leave three hours later with a fully charged battery. Many local municipalities have ordinances that require EVSE or EVSE-ready infrastructure to be included in new construction.

A large parking garage is not necessary to make a destination EV-friendly. Most existing electrical systems can handle the one or two circuits required for a few Level 2 chargers. Therefore, it is becoming more common to see EV chargers installed at hospitals, malls, town halls and parallel spots along busy streets.

Renewables and EV charging go hand-in-hand. Many new project proposals for photovoltaic solar also include EV chargers and a BESS because the infrastructure is shifting toward EV chargers and convenience.

Conclusion

In comparison to EVs, gas-powered cars are less expensive, as is the fuel that powers them, making them a strong competitor against the EV world. Designers, clients and the government must focus on the future of electrification if EV charging is to be as accessible as refueling at a gas station. However, charging already has strong advantages in convenience and technology, which will help catalyze the change in our infrastructure.