Heat pump systems and boiler-based systems can be configured to meet a wide variety of needs for both space conditioning and process loads.

Learning objectives:

- Understand the basic operating principles of boilers and heat pumps.

- Identify codes and standards that govern the selection of boilers and heat pumps.

- Learn the advantages and drawbacks of boilers and heat pumps.

Decarbonization insights:

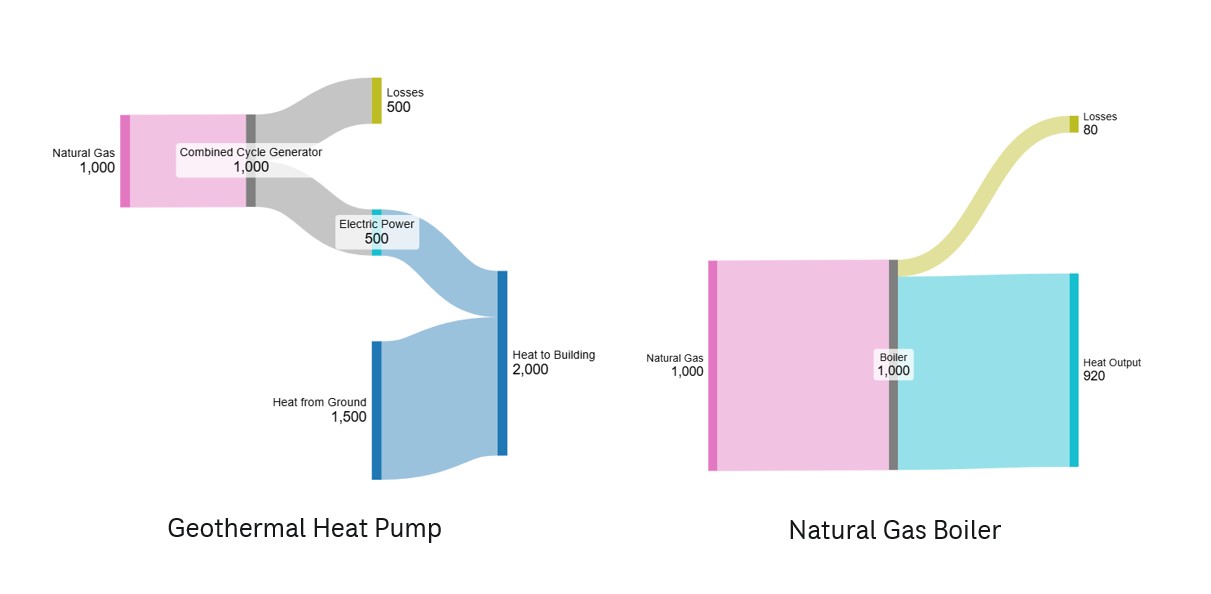

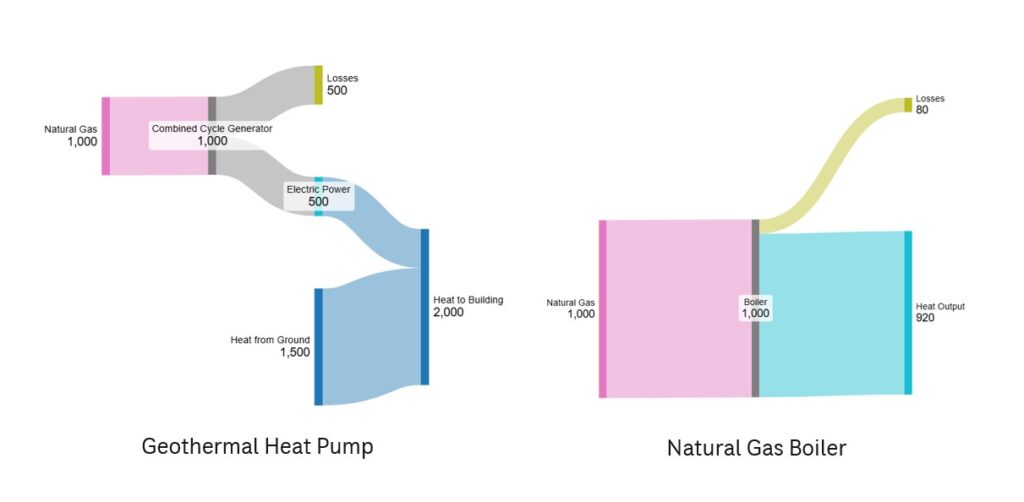

- A boiler takes input energy and converts it to heat, while a heat pump takes input energy to move heat between a source and a sink.

- Important codes related to boiler and heat pump efficiency include the International Energy Conservation Code, ASHRAE 90.1 and ASHRAE 15.

Space heating accounts for almost one-third of the total energy consumption in commercial buildings within the United States. Depending on the climate zone, space classification, ventilation rates and other operational considerations, heating loads within those buildings are commonly met using boiler-based systems and heat pump systems. These systems are used to heat nearly half of the total commercial square footage within the U.S., at 30% for boilers and 15% for heat pumps. The following two system types represent different approaches to heating buildings:

- Boilers use fossil fuel combustion or electric resistance to heat fluid for circulation throughout a building.

- Heat pumps use a refrigeration cycle to transfer heat from an external source to the building.

By making an informed technology selection, users can implement the right system type and tailor the methodologies to meet a range of goals for end users.

Boilers

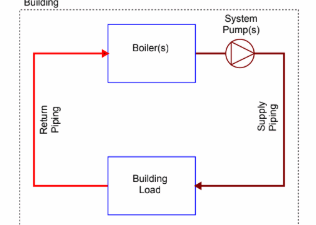

A boiler heating system typically involves a burner, a combustion chamber and a heat exchanger to transfer the produced heat to water or steam. There are multiple types of boiler heating systems, including electric boilers that use an electric heating element in lieu of a burner and combustion chamber. Selecting the best boiler system for a particular application depends on the size and complexity of the facility, as well as the desired temperature range. To determine which system type to use, consider the operating principles of varying types of boilers, their various energy sources, advantages, disadvantages and potential codes or local regulation requirements.

Types of boiler systems include:

- Hot water boilers heat water via natural gas, fuel oil, biomass fuels or electricity to generate thermal energy. Hot water boilers can be used in residential, commercial, industrial and processing applications. The two main types of hot water boiler units are direct-fired and indirect-fired. Direct-fired boilers directly heat the internal chamber, whereas indirect-fired boilers circulate a heated liquid through a coil inside the boiler before being released into the desired areas.

- Condensing boilers are considered high efficiency. They recover additional heat from the flue exhaust gases above and beyond the capabilities of a conventional boiler. The exhaust gases are cooled to the point where the water vapor condenses into liquid water. This condensation releases heat that is subsequently recovered and used to preheat the water returning to the boiler, thus increasing efficiency and reducing fuel consumption. Once generated, thermal energy is distributed to the building end users through a hot water hydronic pumping system. This type of system uses recirculation pumps to convey water through distribution piping to radiators, heating coils and unit heaters throughout the building or facility.

- Steam boilers are used in buildings for various heating applications. These boilers generate electricity by providing a primary motive force through steam turbines. A steam boiler is a closed vessel in which a fluid (typically water) is vaporized by burning fuel, such as natural gas or fuel oil. Once generated, the vaporized fluid (steam) exits the boiler and travels through distribution piping for use in various processes or heating applications at end users throughout a building or facility. Major components required in a steam boiler system include, but are not limited to, the boilers themselves, a burner, gas train or fuel oil storage tank, condensate collection system, deaerator and the piping distribution system.

Boilers are relatively easy to install in comparison to larger water source heat pump systems. Natural gas and fuel oil boilers reduce electrical demand and help minimize the size of the incoming building’s electrical service. However, because they rely on combustible fuels, boilers emit more pollutants than other forms of heating. Therefore, careful consideration is required when selecting a boiler for an application where air quality is a concern. A key consideration when selecting a high-efficiency condensing boiler is to ensure that the return water temperature is low enough to accept heat from condensing vapor in the flue. Overly warm return water temperatures reduce the amount of heat that can be recaptured from exhaust gas, which often results in an efficiency penalty when high supply water temperatures are required.

Heat pumps

A heat pump uses energy input to transfer heat between a heat source and a heat sink, moving energy from a low-temperature side to a high-temperature side against a thermal gradient. This is accomplished through a four-step vapor compression cycle:

- Liquid refrigerant absorbs heat in an evaporator, becoming a vapor in the process.

- This vapor is pressurized in a compressor, thereby raising the saturation temperature of the refrigerant.

- This compressed vapor moves into a condenser and returns to a liquid state, thus rejecting the energy absorbed in the evaporation stage.

- The liquid refrigerant passes through an expansion valve, lowering the pressure back to the initial value, allowing the cycle to begin again.

One unit of energy applied to the compressor can move multiple units of energy between the heat source and the heat sink. The ratio of energy input to energy transferred is the coefficient of performance (COP).

In all heat pump systems, the evaporator is located on the side being cooled, while the condenser is located on the side where heat is being rejected. In a reversible heat pump system, a reversing valve is used to change the direction of refrigerant flow, switching which side of the system is the condenser and which is the evaporator. This allows reversible heat pumps to provide both heating and cooling with a single piece of equipment.

Heat pumps are defined by the media used for thermal sources and sinks, and are categorized into the following three main systems:

- Air-to-air system: Both the condenser and evaporator exchange heat with airstreams (as in the case of a window air-conditioning unit).

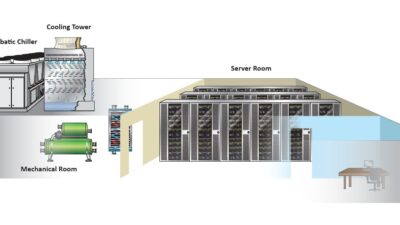

- Water-to-water system: Both the condenser and evaporator are located in fluid streams, consisting of either water or a brine solution. The most common example of a water-to-water heat pump is a water-cooled chiller wherein heat is pulled from a chilled water loop and rejected to a condenser water loop.

- Water-to-air system: Heat pumps locate one condenser or evaporator in a fluid stream and one condenser or evaporator in an air stream. This style of heat pump is commonly seen in geothermal heat pump systems.

Several different heat pump configurations are available for building space conditioning. Packaged heat pumps contain the entire evaporator/condenser apparatus in a single piece of equipment. Depending on the orientation of the unit, a packaged heat pump may be a vertical stack heat pump (VSHP), which stacks the evaporator and condenser on top of one another, a horizontal stack heat pump (HSHP), which places the evaporator and condenser horizontally next to one another, or a rooftop unit, where the evaporator and condenser are packaged into a unit located on the roof of a building and conditioned air is ducted to spaces within the building. Because of their small footprint and larger height, VSHPs are commonly floor-mounted in purpose-built cabinets, while the larger footprint, shorter height HSHPs are commonly mounted in a ceiling space. Split heat pump systems make use of one evaporator or condenser head located inside the conditioned space and the other outside the space, with refrigerant lines connecting the two sides. Split units allow the compressor to be located outside of the conditioned space, resulting in quieter operation. Variable refrigerant flow systems connect many different condenser/evaporator heads, modulating refrigerant flow to each.

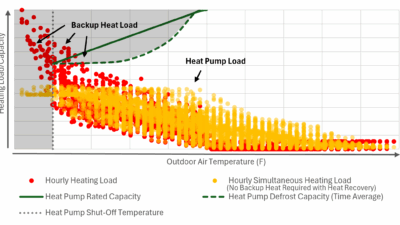

For large buildings, two main configurations dominate: air source heat pump systems (ASHPs) and water source heat pump systems (WSHPs). In an ASHP system, heat pumps draw energy from and reject energy to the ambient air surrounding the building. These systems are always entirely electrically powered. In a WSHP system, a loop of condenser water is routed throughout the building to a network of water-to-air heat pumps and serves as both the heat source and sink for these heat pumps. The condenser water is maintained between a high and low setpoint temperature by either a boiler, cooling tower, dry cooler or ground heat exchange system. WSHP systems can be all-electric or a hybrid combination of fuel-fired and electric. Because the condenser water of a WSHP system tends to be closer in temperature to conditioned air than ambient air is to conditioned air in an ASHP system, WSHP systems tend to exhibit higher COPs.

Water-to-water heat pumps can be used to generate hot or chilled water for building space conditioning or for domestic hot water production. Be careful when designing water-to-water heat pump retrofits for baseboard heating or radiator systems, because heat pump efficiencies are generally reduced at the high water temperatures often used in these systems.

Networked heat pump systems are efficient because they can collaboratively transfer heat energy throughout a building or multiple buildings. When one section of a building requires heating while another requires cooling, heat rejected by a heat pump in cooling can be passed to a heat pump in heating. Water-to-air heat pumps that provide cooling to building spaces are able to transfer heat to water-to-water heat pumps, thus simultaneously heating domestic hot water. Networking heat pumps allows heat input or rejection from the building mechanical system to be reduced to the net of heating and cooling load.

Major equipment required for a heat pump system includes the heat pumps themselves (whether packaged or split) and electrical infrastructure to meet the demands of an all-electric HVAC system. In an ASHP system, the heat pumps themselves are the only thing required for conditioning. No ancillary equipment is required, other than thermal distribution equipment (such as refrigerant piping to connect evaporator and condenser or ductwork to bring conditioned air to the space). In a WSHP system, required ancillary equipment includes condenser water pumps (to circulate heat transfer fluid) and equipment to maintain condenser water temperature (a boiler, cooling tower, dry cooler or ground heat exchange system). WSHP systems can be either ducted or ductless.

Codes and standards

While there are a number of codes and standards that govern the requirements for the installation and operation of boilers, there are a few key codes and standards that specifically impact the efficiency requirements for heating systems. In addition to the International Energy Conservation Code, ASHRAE provides many resources related to the design and performance assessment of heating systems, including ASHRAE Standard 90.1: Energy Standard for Buildings Except Low-Rise Residential Buildings. ASHRAE 90.1, among other guidance, defines the minimum efficiency and operational requirements for heating systems.

Minimum efficiency requirements for heat pump equipment are laid out in ASHRAE 90.1 Table 6.8. In general, efficiency requirements are higher for water-to-air than water-to-water, regardless of source fluid.

ASHRAE 90.1 mandates that gas boilers, ranging from 1 to 10 million British thermal units per hour, must be at least 90% efficient. This has made condensing boilers much more common on new construction projects requiring this boiler capacity level. For larger system sizes, or for systems requiring higher supply temperatures, additional energy recovery measures are implemented, such as air preheating, feedwater preheating, and heat recovery from flue gases.

Safety for heat pump systems is governed by ASHRAE Standard 15: Safety Standard for Refrigeration Systems. Chapter 7 of this standard governs ventilation requirements regarding the quantity of refrigerant in the heat pump system, which may be substantial where A2L refrigerants are used in high-capacity systems.

Choosing the right system

The main difference between a boiler and a heat pump is that a boiler takes input energy and converts it to heat, while a heat pump takes input energy to move heat between a source and a sink. When selecting between a heat pump system and a boiler system a number of factors must be considered:

- Boilers provide higher temperatures than heat pumps, with the capability to produce steam. This generally allows spaces to be brought up to temperature faster, reduces coil and equipment sizes, and opens up the possibility for retrofitting systems designed around high-temperature hot water or steam.

- Recent advances in heat pump technology, including improvements in refrigerants, the inclusion of multi-stage heat pumps, and the use of supercritical fluids, are closing the temperature gap. However, increases in temperatures supplied by heat pumps often come with penalties to efficiency.

- Boilers are a more mature market than heat pumps, with a larger pool of manufacturers and service options to choose from.

- Heat pump systems can provide both heating and cooling, while boiler systems only provide heating.

- Heat pumps allow for full electrification of a building’s heating and cooling. Pursuing electrification requires careful analysis of electrical versus fuel costs. Consider both site and source energy when determining the merits of electrification.

- Boiler and ASHP systems can be sized to meet peak building heating loads, while a geothermal heat pump system must take into consideration the net annual balance between heating and cooling usage to prevent overheating or freezing the condenser water system.

- Heat pump systems can make use of a wide variety of heat sources and sinks, pulling energy from and rejecting energy to ground heat exchangers, sewer heat recovery or surface water heat exchange. By networking systems, it is possible to connect users with high cooling requirements, such as data centers or high rises, with users with high heating requirements, such as low-rise residential buildings.