This article focuses on the different disinfection strategies and technologies available for air handling systems, their effectiveness and their proper applications.

Learning objectives:

- Understand the different components of an air handling unit.

- Learn the different disinfection strategies and technologies that can be implemented in an air handling system.

- Identify the pros and cons to consider when selecting the strategy or technology to implement in a specific application.

Air handling insights:

- Covid-19 put disinfection strategies for HVAC systems top of mind for many building owners and engineers.

- Understanding the pros and cons of different disinfection strategies allows engineers to pick the best option for specific projects.

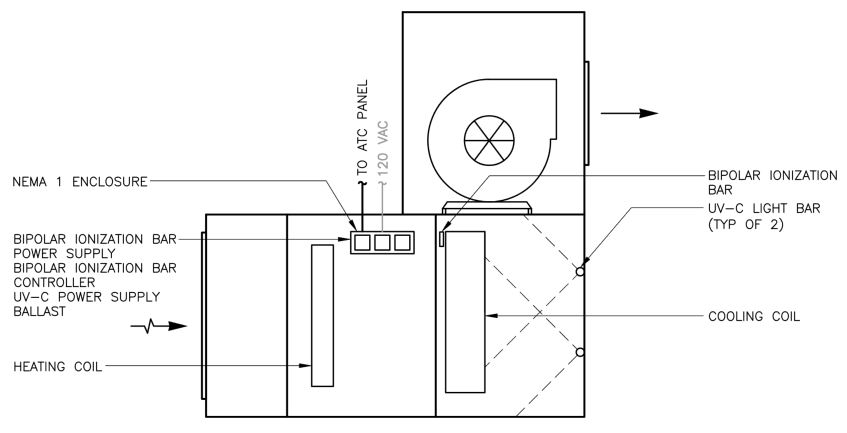

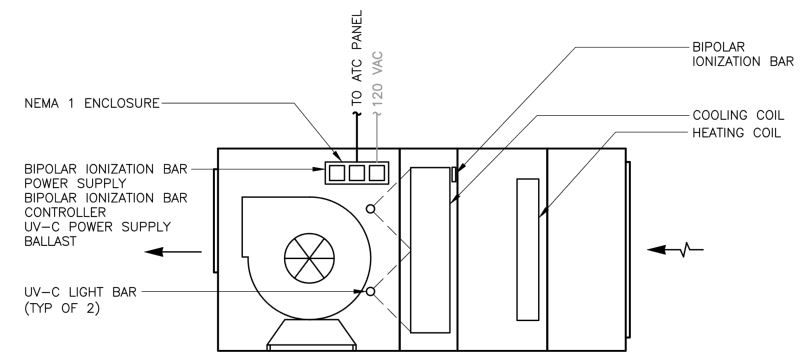

Air handling units (AHUs) are an essential and significant part of the ventilation and conditioning systems developed to better the spaces we live and work in every day. The variability of an AHU’s function, form and location is chosen to best serve the people and products that rely on expected temperatures and air quality. Multiple components comprise AHUs, including filters, mixing boxes, dampers, heating/cooling coils, energy recovery devices and fans. The ventilation and conditioning requirements of a building must be calculated and reviewed to provide the proper selection and combination of components that will satisfy the needs of the building occupants. These components are used in combination to efficiently and effectively condition the outdoor and return air streams of a building’s heating, ventilation and air conditioning (HVAC) system. However, beyond the common contaminants of a workspace or home, there are additional health considerations regarding the passage of air particles and reducing their spread.

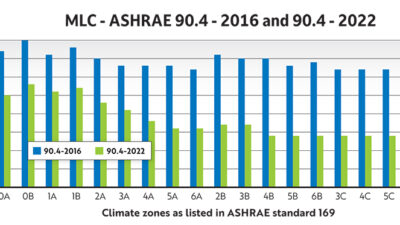

AHUs can vary in capacity and size based on the area, volume and interior design conditions of a space. For example, in a wastewater treatment plant, an AHU can be used to provide continuous airflow at a specific rate defined by NFPA 820: Standard for Fire Protection in Wastewater Treatment and Collection Facilities. In this application, an AHU may only be composed of two parts: a filter section, to remove contaminants from the outdoor air stream, and a heating coil, to condition the outdoor air to keep the space above freezing conditions. To provide ventilation in commercial applications, such as office buildings or schools, several of the components described above may comprise an AHU, as required by the applicable mechanical codes. To provide conditioned air for occupant comfort, an AHU must comply with the required applicable building and energy codes and standards developed by ASHRAE.

In recent years, building owners and HVAC designers have been presented with a more difficult challenge: including the ventilation system of a building in their approach to minimize the spread of airborne diseases. ASHRAE Standard 62.1: Ventilation for Acceptable Indoor Air Quality (IAQ) and ASHRAE 62.2 outline the minimum ventilation rates and measures to help provide acceptable IAQ for occupants and minimize adverse health effects. Building owners and occupants now have an increased responsibility to ascertain how additional measures can be taken to provide a healthier indoor environment that helps reduce the spread of viruses.

Disinfection strategies

With the heightened focus in recent years on HVAC technologies that can disinfect the air supply in any given space, it is equally important to be aware of these technologies’ limitations. These products must be installed correctly to optimize their effect, and the technologies require adequate time to capture the particles and reduce concentrations to mitigate the chance of infection. No existing disinfection system completely eliminates the pathogens in the air. However, it is possible to implement a system that addresses the concerns and realities of a world focused on public health and decreasing the spread of diseases through air ventilation. As with any HVAC design, this goes beyond required code, and there are likely additional costs and installation constraints. Understanding the disinfection options and limitations for an AHU provides realistic expectations for installation and disinfection levels. A thorough site review and investigation are required to determine the feasibility of implementing these strategies on existing equipment and retrofits, which is largely dependent on the existing conditions of the equipment. It is more feasible to apply the strategies outlined below to new build projects.

Strategy one

The first strategy for providing disinfection includes increasing ventilation rates and providing room differential pressurization. As stated in ASHRAE’s “Position Document on Infectious Aerosols”, published in April 2020, the majority of larger emitted droplets greater than 100-micron size are drawn by gravity to land on surfaces within a radius of three to seven feet. Some larger droplets evaporate to 10-micron size as they travel and land much farther away. Aerosols less than a 10-micron size can remain airborne for hours and travel longer distances to infect secondary hosts who had no contact with the primary host. ASHRAE determined that increased ventilation rates and room differential pressurization did not reduce the short-range transmission of larger particles but did help to dilute the transmission of aerosols less than 10-micron size. This means that increasing airflow to a space can limit the spread of airborne particles of a certain size. ASHRAE also noted that the effective directional airflow created clean-to-dirty airflow patterns to move aerosols toward exhaust locations. Though airflow designs likely incorporate these patterns of supply to exhaust already, the design is reinforced through this strategy.

Furthermore, many space types are not currently designed to meet the six to 12 air changes recommended for airborne infection reduction. This may again be a factor in updating an existing system or a reason for limits in the expected capabilities of an AHU. Being mindful of the air changes that lessen the spread of infection is an important basic component of disinfection that can be used in conjunction with further technology to achieve the best results. The operating and maintenance costs of increasing ventilation rates, however, will likely be higher than with other strategies, and increasing the ventilation of an existing unit could involve installing a new motor or a new supply air blower, depending on the increased airflow.

Strategy two

The second strategy is to improve the air filtration efficiency ratings. ASHRAE determined that high-efficiency filters, filters with a minimum efficiency reporting value (MERV) of 13 or greater, installed in central AHUs reduce the airborne load of recirculated infectious particles. However, the filters will not eliminate all risk of transmission of airborne particles due to other factors that contribute to disease transmission, such as infectious aerosol concentration. Researchers at the Illinois Institute of Technology found, “HVAC filtration for controlling infectious airborne disease transmission in indoor environments: Predicting risk reductions and operational costs,” that, “recirculating HVAC filtration was predicted to achieve risk reductions at lower costs of operation than equivalent levels of outdoor air ventilation, particularly for MERV 13–16 filters.”

The recommended high-efficiency filters have significantly higher pressure drops that require an increase in fan horsepower, energy and, occasionally, more installation space inside the AHU. Thus, existing systems may not have adequate motor sizes or cabinet space to accommodate these filters.

Strategy three

The third strategy includes ultraviolet lights with nanometer wavelengths within the C band (UV-C). UV-C lights inactivate microorganisms by damaging the structure of nucleic acids and proteins within the microorganism, depending on the UV dose and susceptibility of the microorganism. The UV dose is intensified by decreasing the distance between the UV source and the microorganism and by increasing the exposure duration. Historically, UV-C applications treated specific surfaces within HVAC systems, such as cooling coils and condensate drain pans. UV-C lamps were mounted inside AHUs perpendicular to the airstream, downstream of the cooling coil, to project their light back onto the coil and drain pans, preventing microbial growth on surface areas.

UV-C is applied inside distribution ductwork to destroy airborne microorganisms in the air stream as they travel down the length of the UV-C device. By traveling the length of the device rather than perpendicularly, the light provides more exposure time to damage the cellular structure of the pathogens. Tests indicate killing vegetative bacteria is successful, but smaller-sized bacterial spores are more difficult to kill, yielding an approximate 90% success rate.

Retrofitting existing AHUs is nearly impossible because the lamps are typically 48 to 60 inches in length, and commercial air handling compartment sizes are typically designed to provide about 30 inches in width. Designers often misapply UV-C lights in AHUs because they do not recognize the correct positioning needed for lamp orientation to kill airborne microorganisms, versus those on a surface. Again, paying special attention to ensure that the UV lights are installed either perpendicularly to the airstream or, ideally, the length of the unit will make a difference in how well this method works to meet designer and owner benchmarks for disinfection.

While it has been argued that upper room germicidal UV air disinfection is the most effective approach toward stopping the spread of airborne diseases, measuring a relative economic efficiency more than nine times higher than rate with ventilation alone, the proper installation of such technology can have a significant impact on effectively limiting the spread of airborne pathogens within an indoor environment.

Strategy four

The fourth strategy is the generation and distribution of ozone particles to attach and remove microorganisms from air streams and airborne microorganisms within building spaces. Ozone is the product of separating oxygen molecules (O2) that then collide to form ozone (O3). In April 2020, the University Institute of Cardiology and Pneumology of Quebec published an article titled, “Ozone efficacy for the control of airborne viruses: Bacteriophage and norovirus models.” The article detailed how low concentrations of ozone reduce virus infection when applied with high relative humidity. Ozone eliminates viruses by damaging the ribonucleic acid of the virus.

Although it is effective for air disinfection, ozone in concentrations exceeding five parts per billion is harmful to human health. The low concentrations of ozone employed in the study were at least 0.23 parts per million. Exposure to ozone creates risk for a variety of symptoms and diseases associated with the respiratory tract. Many products of ozone homogeneous and heterogenous reaction processes also increase risks to human health, including formaldehyde, unsaturated aldehydes (produced during the reaction of ozone with ketones and alcohols) and ultrafine particles less than 10-micron size. Remediation strategies involving ozone are best used in low-occupancy spaces during unoccupied times, such as at night, when the ventilation system has had an adequate period to remove the microorganisms and remaining ozone particles from the space. It is often used in medical or hospital settings where a certain level of disinfection is necessary. Caution should be applied with this technique when looking to implement it elsewhere.

Strategy five

The fifth strategy involves the generation and distribution of positive and negative oxygen ions to attach and remove microorganisms from air streams and airborne microorganisms within building spaces. The positive ions are missing an electron, while the negative ions contain an extra electron, thereby resulting in an unstable condition. To restabilize, the bipolar ions search for and trade electrons by seeking out the airborne particulates, bacteria, aerosols, volatile organic compounds and odors in the space or distribution pathways. This process increases the size of the harmful pathogens into larger clusters as ions are added. Those particles then return to the central AHU, where they are more easily captured by the filters. As the captured pathogen clusters divide to reproduce, they bond with oxygen ions, thus destroying the microorganisms. It is important to note that the concentration level of the ions begins to reduce after 100 seconds, which ultimately limits their total count available to attach to the contaminated molecules after that time frame

Bipolar ionization bars are small, lightweight and easy to retrofit on the leaving face of cooling coils to prevent air flow obstruction. Special attention should be paid to the veracity of manufacturers’ claims for these technologies because there are inconclusive viewpoints regarding the safety of introducing ions as a disinfecting method. A 2022 study by the Toho University Department of Infection Control and Prevention, titled, “Evaluation of a bipolar ionization device in inactivation of antimicrobial-resistant bacteria, yeast, Aspergillus spp. and human coronavirus,” reported that bipolar ionization, specifically for healthcare spaces, is largely understudied and requires more information before its efficacy is entirely understood. This method would be the easiest to retrofit to an existing unit; however, without combining it with another method, such as increasing the ventilation or the filter efficiency, it would not be as effective or useful. Therefore, bipolar ionization should not be the sole solution towards air disinfection, but it has the potential to reduce the spread of airborne diseases.

Like any technology, these techniques continue to be studied and will develop in relation to our understanding of infection and what can be done to mitigate the spread of diseases. Cognizance of how impactful a certain device or system is toward disinfection means going beyond marketing language and designing around an AHU that is a part of a greater whole. Creating a holistic HVAC design that considers disinfection strategies presents a broader understanding of what an AHU can provide in terms of overall building design, and ultimately contributes to a better use of the power and maintenance put toward operating the unit. While the applications of these strategies are often in medical settings, HVAC engineers and building owners may look at how they can better serve the health of the occupants of any building with a number of these disinfection approaches.