Retrofits of existing buildings added a networked geothermal system in Massachusetts.

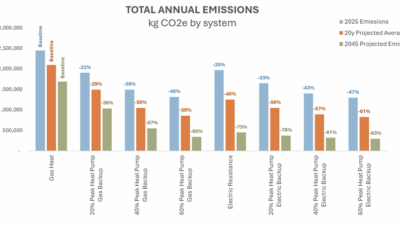

The evolution of central heating and cooling systems, with the ever-increasing quest for improved efficiency and fossil fuel reductions, has led to the increased use of geothermal systems and the development of networked geothermal systems.

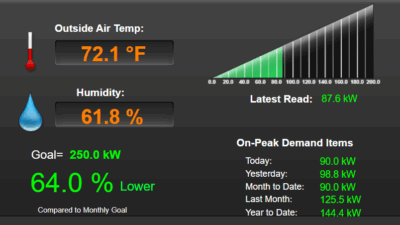

Networked geothermal systems share energy with multiple thermal resources and use the ground as a heat sink and source when the distributed loads are unbalanced. A geothermal distribution network shares many characteristics of a chilled water distribution system.

The temperatures vary from 30°F to 90°F using a 30% propylene glycol heat transfer fluid. The wide variety of flows and pressure drops within the different loops makes the primary/secondary arrangement ideal.

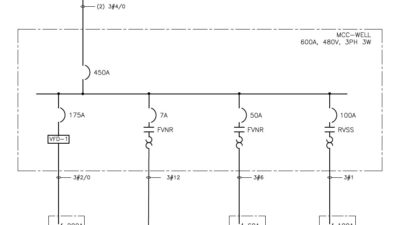

One example of such a project was performed for Eversource in Framingham, Massachusetts. This project involved retrofitting existing buildings with new heating and cooling equipment. The primary distribution piping is served by a new pumphouse comprising the primary distribution pumps and controls.

The buildings are decoupled from the utility network with a heat exchanger connected as a secondary loop to the primary loop. These energy transfer stations are in belowground vaults. These vaults allow for public utility access to the energy transfer equipment without entering the building or using valuable customer floor space.

Similarly, the geothermal bore fields are connected as secondary loops. The 500-foot-deep bores with 1,000 feet of 1.25-inch-diameter heat transfer piping have a high pressure drop; therefore, having these as a secondary loop decreases overall pumping horsepower.