Hot water heating boilers are used widely in residential, commercial and institutional buildings

Learning Objectives

- Identify the major components of a boiler.

- Differentiate types of water boilers.

- Learn the codes and safety requirement for hot water boilers.

Boilers are one of the chief energy-producing systems in buildings, providing space heating as well as domestic hot water supply to buildings and occupants. Boilers create either steam or hot water to distribute thermal energy between and within buildings.

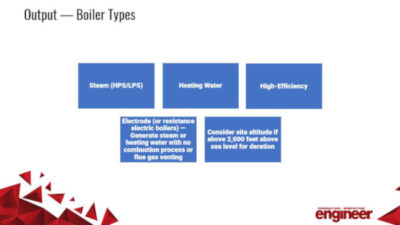

Steam and high-temperature hot water systems are typically found in large facilities because the higher energy intensities keep equipment and piping sizes smaller. For some commercial, health care and industrial facilities, the steam may also be used for other purposes as well as comfort heating.

However, the high energy content of these systems results in lower efficiencies and higher energy losses. These high-energy systems also come with safety risks that require specialized construction requirement and operational skills. For this reason, hot water systems are more economical from construction, energy and operational standpoints for many smaller systems.

The American Society of Mechanical Engineers and the Boiler and Pressure Vessel Code, Section IV, Rules for the Construction of Heating Boilers, define the requirements for hot water and steam heating boilers versus the requirement for power boilers, which are used mainly for power generation and other industrial uses. Heating boilers generate steam less than 15 pounds per square inch gauge or water less than 250°F. This article will focus on hot water boilers only.

Boiler basics

All boilers have four main components: the burner, the combustion chamber, the heat exchanger and controls.

Burner: The burners function is to mix air and fuel to optimal proportions for complete and efficient combustion and provide an ignition source for the mixture. Oil burners typically use a forced draft burner with fuel atomization using a pressure nozzle, air or steam. Gas burners can use either a forced draft fan or use natural draft with the gas delivery through a series of orifices.

The most common fuels in today’s boilers are fossil fuels: natural gas and #2 fuel oil, as fuel distribution is widely available and controls and efficiency improvements have been focused on these fuels due to their prevalence.

In the early history of boilers, solid fuels were most common, as these were the most readily available. Coal and wood were the most common. Coal has lost its popularity, mostly due to its high sulfur content and the associated pollution created by combustion. Wood has regained some popularity along with other biomass fuels due to its sustainability.

Waste heat from another process such as in internal combustion gas engine or turbine exhaust can be used as the heating source in lieu of burning fuel in a boiler. Another source of energy that could gain popularity is electricity. Hot water generated by an electric boiler produces no greenhouse gases at the site. Where electricity can be generated from 100% renewable sources an electric boiler is a zero-emission heat generator.

Combustion chamber: Combustion requires three components: fuel, oxygen and heat. All three of these must be controlled to efficiently control a boiler. The rate of fuel being supplied is controlled to match the requirements of the process to maintain the boiler temperature. The rate of oxygen, as a component of air, is controlled to provide complete stoichiometric combustion of the fuel. Too little air and not all the fuel is not burned, resulting in pollution, including hazardous carbon monoxide and wasted fuel. When excess air is supplied energy is wasted as the excess air robs heat from the flame.

High flame temperatures also cause nitrogen to react with oxygen and creates oxides of nitrogen, commonly referred to as NOx. Flame temperature can be controlled by recirculating a portion of the flue gas and mixing it with the incoming combustion air, this reduces the oxygen available to the combustion process. The recirculated gas does not rob heat from the combustion process because it is already hot. Heat is provided to initiate combustion via a spark and/or pilot flame. Combustion is usually self-sustaining once it is established.

This combustion process typically occurs in a combustion chamber within the boiler. This section of the boiler is often also referred to as the furnace. The combustion chamber walls are also heat exchanger surfaces for internally fired boilers. Radiation is the primary mode of heat transfer from the flame to the water in this section of the boiler. The heat source can also be from a source outside of the boiler. Heat from a combustion turbine or waste heat from a process can be directed to boiler. These are examples of external heat sources.

Heat exchanger: Past the end of the flame zone, the hot products of combustion and unconsumed portions of the air pass through narrower heat exchange channels and heat is transferred via convection and conduction.

There are three main configuration of heat exchangers in boilers: water-tube, fire-tube and cast-iron sectional.

A water-tube boiler is one in which the fluid to be heated passes through a series of pipes or tubes and the combustion gases are external to the tubes. Heat from the combustion gases passes through the metallic tube walls. Large water-tube boilers are constructed with ferrous materials.

Traditionally, water-tube boilers were used for large-capacity boilers, however, with the advent of low-mass and condensing boilers, a water tube configuration has become more common for low-capacity boilers. The water tubes for these smaller boilers are made of a corrosion resistant material.

Fire-tube boilers have large diameter tubes located in a large drum. The fire combustion gases pass though these tubes, heating the water in the large drum. The fire tubes are typically arranged horizontally. The boilers can also be arranged in a vertical configuration to reduce footprint. In condensing application vertical configuration also simplifies drainage of condensed flue gases.

Fire-tube boilers are classified by the number of passes the combustion and combustion products make. The first pass consists of the large diameter cylindrical fire box. The hot gases make a 180-degree turn a second pass through a series of smaller tubes. The gases again turn 180 degrees; typically, the third pass has smaller bore tubes but more tubes than the second pass. Three or four pass boilers are the most common.

A horizontal boiler with an even number of passes will have the flue connection near the front of the boiler and an odd number of passes has the flue at the back end. The back of the boiler is constructed with a refractory lined door (dry back) or water filled (wet back). The wet back boiler is more difficult to construct and requires extra seals, so it is more expensive, but the increased heat transfer area improves efficiency. Fire-tube boilers are constructed of ferrous metals.

Cast iron sectional boilers are made of modular cast iron sections. The combustion chamber is low in the boiler and surrounded with water channels. Hot combustion gases typically turn up and toward the front of the boiler then back toward the back, similar to a three-pass fire-tube boiler, but instead of the gases passing though tubes, the gases pass through extended surface gas channels on the exterior of the castings. The water is contained inside the castings. Each cast section is connected to the adjacent section with tapered connectors that are compressed when the sections are bolted together.

There are several advantages to a cast iron sectional boiler. The cast iron material is more corrosion-resistant than the steel used in water-tube and fire-tube boilers. A boiler can be moved into place one section at a time through a building’s doors or windows. Due to the modular nature, the capacity of a boiler can be adjusted by changing the number of cast iron sections used.

Boiler controls

All boilers require control of three basic elements to operate safely and efficiently: water flow, air flow and fuel flow. The heat exchange surfaces for hot water boilers must be in contact with water to prevent the heat exchange surface from overheating. Low level water sensors are required to ensure this.

Fuel and air are controlled in concert, but the quantity of fuel delivered is a function of thermal input required to control the boiler temperature. The air is then controlled to optimize the combustion process.

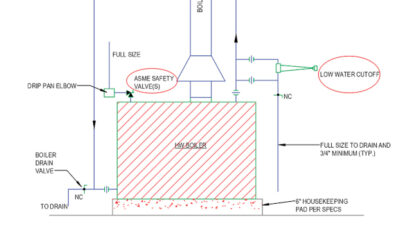

The model code for hot water boilers is the ASME BPV Code Section IV. This code lists six safety features every hot water boiler must have:

- A pressure or altitude gauge. This gauge helps the operator to determine if the boiler is properly filled with water and if the expansion compensation in the system is operating.

- A thermometer. This also allows the operator to determine proper operation of the boiler and to confirm operation of the required temperature controls.

- Two temperature controls. If the boiler is automatically fired, the first one is considered the operating control. The second is a high-limit safety shut-off control. Most jurisdictions require the high-limit control be equipped with a manual reset switch.

- An automatic low-water fuel cutoff. Most jurisdictions require a low-water fuel cutoff with a manual reset switch. A second low-water switch is required if the boiler is automatically fired and has a heat input greater than 400,000 Btu/hour. This switch is located above the low limit safety and interrupts the burner in the case of low water and may allow the boiler to restart once the water level is restored. Low-mass water-tube boilers often also require a proof of water flow through the boilers. Because of their low-mass, overheating is nearly instantaneous if water flow is stopped.

- Provisions for thermal expansion. Water expands as it is heated, causing the system pressure to rise. A thermal expansion system gives this increased volume of water a place to go.

- Pressure safety relief valve. In addition to the thermal expansion system, a pressure safety relief valve is required. This valve will operate if the expansion system fails or the boiler is valved of from the system and is accidentally fired. The safety relief valve is directly connected to the boiler without isolation valves. The valve is set below both the boiler’s and any other system components’ pressure rating. The valve size must prevent the design pressure of the boiler from being exceeded in the case of water flow blocked from escaping the inlet and outlet piping and the burner at full fire. A relief valve rating includes both the relief pressure and the Btu firing rate for the boiler.

Condensing boilers

To increase a boiler’s efficiency above the 85% threshold, the flue gas needs to be allowed to condense on the heat transfer surface. Efficiency of these condensing boilers is greatly increased by both lowered allowable water temperature, which improves log mean temperature difference of the heat transfer mechanism and by recovering the latent heat of vaporization from the fuel’s combustion. Efficiency of condensing boilers can be as high as 95% to 98%.

Condensation is allowed by using metals, such as copper, aluminum or stainless steel and even some specialized cast irons. Manufacturers and researchers have also experimented with ceramics and other composite materials. In condensing applications, contaminants in the fuel — particularly sulfur — needs to be minimized. Therefore, natural gas is most commonly used as a fuel source, but ultralow sulfur fuel oil is allowed by a few boilers.

Due to the high energy efficiency and improved design of lower temperature hot water boilers, condensing boilers have been increasing in popularity.

Corrosion in boilers

Corrosion of boilers is a major source of boiler failure. Corrosion occurs on both the water side and the fire side. Corrosion on the water side is caused by oxygen in the water. In a tightly closed system, little to no water treatment is required because oxygen is absorbed as piping rusts but stops as soon as all oxygen is consumed. On larger and/or leaky systems where make up water is constantly required, water side corrosion can be controlled by adjusting acidity, alkalinity and oxygen by the addition of chemicals. Biocides and scale inhibitors are often added.

Water chemistry is usually manually checked and adjusted as a hot water system required a lot less makeup water than a steam system. Flue side corrosion is caused by condensing of flue gases on the heat transfer surface or chimney. Condensation in the chimney can flow into the boiler to cause this corrosion. This condensation is highly acidic due to sulfur in the fuel and chlorides in the atmosphere. When these compounds condense, they combine with the water vapor in the flue gas and create strong acids.

The simplest way to control this condensation is by keeping the flue gas temperature and adjacent surfaces above the dewpoint of the flue gas. This requires the flue temperature to remain above 350°F. Temperature means that maximum achievable efficiency of a boiler is in the low to mid 80% range.

Boiler codes, requirements

Clearances on the front, rear, sides and top of boilers for operation, maintenance and inspection must meet jurisdictional requirements. If no jurisdictional requirements exist, then the boiler manufacturer’s requirements are to be met. The specifying engineer needs to take care in determining these requirements.

Often these requirements are not found in the building codes, but are governed by other agencies. For instance, in New York, the Department of Labor defines many of the parameters listed above and additional requirements such as access ladders to the top of boilers.

The primary codes governing boiler controls are ASME CSD-18 Controls and Safety Devices for Automatically Fired Boilers and NFPA 85: Boiler and Combustion Systems Hazard Code. CSD-1 applies to boilers up to 12,500,000 Btu/hour. Many local and international codes incorporate parts of these two codes into their wording. The following discussion highlights some of the requirements found in the codes. Refer to the codes for exceptions and, in some cases, more stringent requirements than are described here.

Often overlooked requirements of boiler controls are the requirements for wiring of external devices not provided with the manufacturer provided controls. One is the requirement for interlocking the boilers with the source of combustion air. The intake dampers or combustion air fans are not integral components of the controls often supplied by the burner manufacturer. Another external control element is the remote shutdown switch. This requirement is defined in CSD-1 CE-110 (b). These elements external to the burner/boiler controls require the specifying engineer to include these interface requirements in the design documents.

Hot water boilers have several advantages over larger power boilers in small systems. Condensing boilers have become the most commonly installed boilers in new installations, where the entire system is designed to take advantage of the increased efficiency afforded by lower water temperatures. The lower complexity of hot water boilers and hot water systems have a proven history of safe, reliable and efficient operation when properly installed and maintained and can save costs for the owners over the life of the system.