Industrial HVAC systems serve needs far beyond comfort. They often support critical, specific industrial processes and even ensure life safety for residents, customers and workers.

Learning objectives

- Understand what industrial HVAC systems are and why they are important.

- Learn about different types of industrial HVAC systems and their advantages and disadvantages

- Understand the types of processes where industrial HVAC systems are applied

HVAC insights

- Industrial HVAC system types include air-based, refrigerant based and hydronic systems.

- Engineers must consider local and national codes including ASHRAE standards, OSHA requirements and EPA considerations.

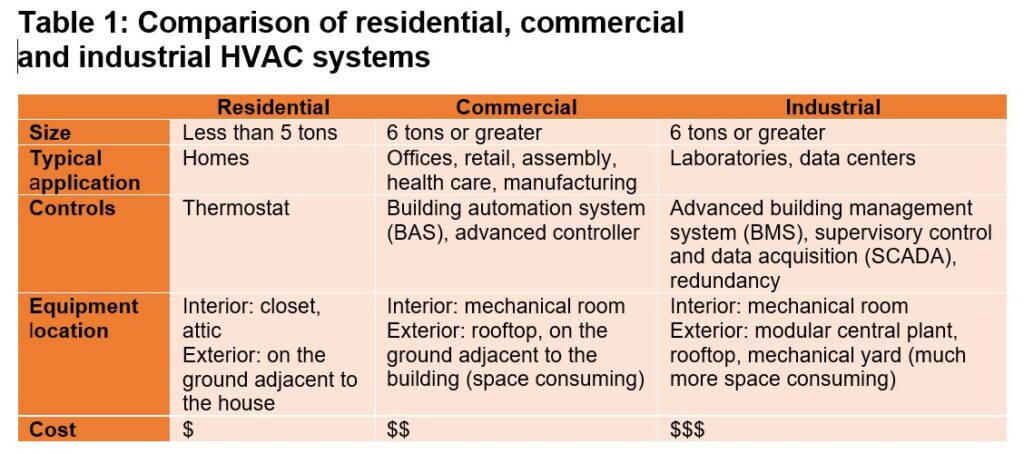

Industrial HVAC systems serve large-scale buildings such as warehouses, health care facilities and water and wastewater treatment plants. Although industrial HVAC systems operate similarly to residential HVAC systems, they are typically larger and more complex. Industrial HVAC systems are crucial for many large-scale processes to function properly.

Types of industrial HVAC systems

HVAC systems used in industrial and commercial buildings can be broadly categorized by the primary medium they use to transfer heat: air, water, refrigerant or a combination. Each system type presents distinct advantages, limitations and design implications depending on the building’s size, function and environmental control needs.

Air-based HVAC systems use air as the heat transfer medium to provide heating or cooling to a space. The overall principle generates heat by combustion of fuel or moves heat via the operation of a refrigerant compressor. Heat exchangers are employed to transfer heat from the combustion or refrigeration process to the airstream. Air-based HVAC systems are simple to design and install, have high ventilation capacity and are effective in environments that require dilution of airborne contaminants. However, these systems can have bulky ductwork that takes up a significant amount of space, and the systems are less efficient at precise zone temperature control than fluid mediums. The most common type of air-based HVAC system is the air-to-air heat exchangers.

Hydronic HVAC systems use water or steam as the heat transfer medium to provide heating or cooling to a space. Common types of hydronic systems are radiators, fan coil units, chilled water systems, cooling towers and water-source heat pumps. Advantages of hydronic systems include smaller distribution components (piping versus ductwork), high-energy efficiency, the support of precise temperature control in multi-zone applications and low maintenance requirements. Some downsides to hydronic systems are that they may require a separate system for ventilation, and the system design and controls are more complex. Hydronic systems also pose the risk of leaks, freezing or corrosion in certain climates or applications.

Refrigerant-based HVAC systems use a refrigerant as the heat transfer medium to provide heating or cooling to a space. Examples of refrigerant HVAC systems include direct expansion (DX) systems and variable refrigerant flow (VRF) systems. Refrigerant systems provide efficient heat transfer, are flexible and scalable, and provide simple and efficient temperature control. However, refrigerants can be harmful to the environment if released into the atmosphere. Some forms of refrigerants also have toxicity and flammability concerns. ASHRAE Standard 15: Safety Standard for Refrigeration Systems sets guidelines for the safe design, construction, installation and operation of refrigerant systems. Because ASHRAE 15 is consistently updated for industry needs and legal requirements, this can create additional challenges when designing DX systems.

Glycol is used in HVAC systems as a heat transfer fluid. Glycol solutions typically include water and a specific concentration of glycol, typically either ethylene glycol or propylene glycol. Glycol prevents freezing in cold temperatures, inhibits corrosion and improves system efficiency and longevity. However, glycol also poses toxicity issues and systems using glycol solutions require specific monitoring of the concentration and chemical stability of glycol. Common HVAC systems that use glycol solutions include chilled water systems, hot water systems and heat recovery loops. Improper handling of ethylene glycol can pose serious environmental risks. To minimize these risks, the U.S. Environmental Protection Agency (EPA), the Occupational Health and Safety Administration (OSHA) and the National Institute for Occupational Safety and Health guidelines should be followed, which include protocols for spill prevention and secondary containment, proper ventilation for worker safety and waste management.

In more complex HVAC systems, the heat transfer medium to provide heating or cooling to the space is a combination of at least two of the air, water, or refrigerant media. In a hybrid, or combination, system, one medium is responsible for carrying most of the load and the other medium handles the remainder. An example of this is a refrigerant-based dedicated outdoor air system (DOAS) unit with hydronic terminal units.

HVAC systems can be further categorized by their components, overall configurations or their heating and cooling methods.

Split systems

The most common types of ducted systems are split systems. Split systems feature an indoor unit (air handler and evaporator coil) and an outdoor unit (condenser and compressor). Split systems may be single-split or multi-split systems. Single-split systems have one air handler and a corresponding outdoor unit and are the most commonly used configuration. Multi-split systems allow multiple indoor units to connect to one outdoor unit. Split systems have several benefits, including cost-effectiveness, improved indoor air quality through filtration and the provision of cooling. In industrial settings, larger commercial-sized split systems (six to 25 tons) are typically used. Smaller, residential-sized units (up to five tons) are common for smaller spaces.

Packaged heating and cooling units

Packaged heating and cooling systems are commonly found in commercial and industrial settings. A packaged system has the heating and cooling components housed in a single unit. These units are typically positioned on a roof, in an attic space, outside on the ground or mounted on an exterior wall. The packaged unit is then connected to the building’s distribution ductwork through penetrations in the building envelope. Benefits of packaged HVAC systems include cost savings in both energy and installation, energy efficiency, space efficiency and ease of maintenance.

VRF and variable refrigerant volume systems

VRF systems and variable refrigerant volume (VRV) systems are typically installed in larger commercial spaces because of their ability to meet varying loads throughout buildings. These systems run on a similar principle to multi-split systems by connecting multiple indoor units, typically ductless split systems, to a single outdoor unit. VRF/VRV systems vary the flow of refrigerant to the indoor units based on the demands of each individual area. There are different types of VRF/VRV systems, including air-cooled, water-cooled, two-pipe and three-pipe systems. Heat recovery VRF/VRV systems provide optimal zoning control by providing simultaneous heating and cooling. Advantages of VRF/VRV systems include increased energy efficiency and energy savings, reduced ductwork, precise temperature control and flexible design. The disadvantages of VRF/VRV systems include high initial costs, complex components, complex installation and maintenance, refrigerant leaks leading to environmental concerns, the need for A2L refrigerant consideration and the need for a separate dedicated ventilation system.

Ductless mini-split systems

In large-scale industrial applications, smaller-scale residential units are sometimes needed. For example, a small electrical room or server room might have a small cooling load with limited space requirements that need to be separated from the whole system. Ductless mini-split systems are similar to typical split systems, with an indoor unit and an outdoor unit. However, they do not have associated ductwork. Ductless mini-splits are a good choice for zoned air-conditioning systems without the ductwork requirement. Ductless mini-split units are typically used for areas that require small cooling capacities, with most units available on the market ranging from half a ton to three tons. Advantages of ductless mini-splits include small size, easy installation, energy efficiency and design flexibility with different indoor unit installation methods. However, ductless mini-splits are generally more expensive than central systems and provide lower air filtration.

Importance of industrial HVAC systems

Many industrial buildings house large-scale equipment, such as motors and pumps, that are essential for day-to-day operation. This equipment can produce large amounts of heat that is transferred to the surrounding building space. To mitigate and reduce the effects of this heat load to the space and other critical equipment and materials, industrial HVAC systems are used. Critical equipment and materials include variable frequency drives (VFDs), batteries and building materials. Keeping these critical items at an optimal temperature is essential for facility operation and for safety.

Industrial processes can generate contaminants such as dust and vapors that can compromise indoor air quality. Effective HVAC systems help reduce or eliminate these contaminants, resulting in better indoor air quality for people. The large capacity and increased complexity of industrial-sized HVAC equipment can also provide a higher degree of humidity control. Improper humidity levels can result in condensation that can lead to mold growth and corrosion. Both issues can affect the integrity of equipment and the health of inhabitants, including workers.

Designing industrial HVAC systems

Designing an industrial HVAC system requires a comprehensive understanding of both the operational requirements of the facility and the physical characteristics of the environment. Unlike commercial or residential systems, industrial HVAC design must often accommodate large-scale processes, fluctuating loads, specialized air quality needs and strict regulatory standards.

The key steps in designing industrial HVAC systems follow.

- Perform detailed load calculations for heating and cooling. Internal loads include heat generated by machinery, lighting and occupancy. External loads include solar gain, building envelope insulation and outdoor air conditions. Process loads include specific thermal or ventilation demands tied to manufacturing or chemical processes.

- Select equipment. Choose appropriate HVAC equipment based on load calculations and factors such as budget, efficiency, space constraints and indoor air quality requirements. Consider the environment in which the equipment will be installed to determine whether corrosion-resistant coatings are required.

- Determine airflow requirements and duct design. In industrial settings, proper airflow is essential for comfort, process stability, product quality, and safety. Key considerations include: air change rates, especially in areas with high pollutant loads or temperature swings; duct sizing and layout to minimize pressure losses and noise; high-velocity versus low-velocity systems, depending on the application; the use of industrial-grade materials for ducts and fittings to withstand contaminants, heat or corrosive substances; integration with building automation systems (BAS) and building management systems (BMS). A robust BAS/BMS provides centralized control and monitoring of HVAC equipment. This enables real-time data collection for diagnostics and performance optimization, integration with other building systems (e.g., lighting, fire suppression, security), predictive maintenance alerts and remote monitoring.

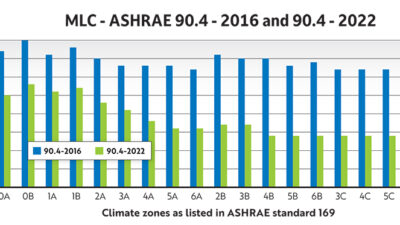

- Compliance with standards. Designs must comply with applicable local, national and industry standards, including: ASHRAE Standard 62.1: Ventilation for Acceptable Indoor Air Quality, ASHRAE Standard 90.1: Energy Standard for Buildings Except Low-Rise Residential Buildings, EPA guidelines on emissions and refrigerant handling, ISO standards and OSHA requirements.

Critical industries for HVAC systems

HVAC systems in pharmaceutical areas help with air cleanliness, pressurization requirements and temperature/humidity requirements to maintain the integrity of some medications.

Data centers, unlike most buildings, are primarily concerned not with occupant comfort but with keeping massive servers and equipment functioning properly. HVAC systems in data centers help offset the great amount of heat put off by the electrical equipment in these spaces. The goal for HVAC systems in data centers is to maintain a tightly controlled temperature range with minimal energy consumption. Highly efficient cooling systems are typically used, including chilled-water loops, air-side economizers or liquid-immersion cooling. Redundant systems are often provided owing to the criticality of these spaces. ASHRAE Standard 90.4: Energy Standard for Data Centers details the strict requirements for data center HVAC systems.

HVAC systems in chemical rooms are often provided for the life safety of workers and to aid in maintaining the chemical’s stability and effectiveness. Precise temperature and humidity control are needed to manage chemical reactions and prevent hazards.

HVAC systems can be critical in manufacturing processes. For example, in semiconductor fabrication facilities, clean rooms are often required. These have boundary conditions for temperature, humidity, filtration for air particles and pressurization.

Water and wastewater treatment plants rely on HVAC systems for accurate temperature control and air quality management. Many processes take place within water and wastewater treatment plants that are essential to plant function. The chemical processes taking place at a facility may require an HVAC system to ensure the integrity of the chemicals used. It is important to consider material and equipment integrity, along with the safety of maintenance personnel, when providing HVAC systems for these plants. Water and wastewater treatment plants also rely on large-scale electrical rooms that are crucial to the entire plant’s operation. Like data centers, electrical rooms that serve crucial infrastructure often have redundant systems to ensure electrical equipment, such as VFDs, are functioning properly.

Certain government facilities have more extreme, mission-critical HVAC requirements beyond the standard human comfort factor. These include aircraft paint rooms, where filtration, temperature and humidity requirements apply for human safety and for the painting process, and aircraft battery maintenance areas, where temperature requirements apply for storing and charging/discharging batteries to ensure battery service life. Specific exhaust system requirements may also apply in the event of thermal incidents.

Industrial HVAC systems are important for the safe and efficient operation of large-scale facilities across diverse sectors like pharmaceuticals, data centers, chemical plants and manufacturing. Unlike their residential counterparts, these complex systems are specifically designed to manage substantial heat loads, control airborne contaminants, regulate humidity and maintain precise environmental conditions crucial for equipment integrity, product quality and worker safety. The choice of system type, along with configurations like split, packaged, VRF/VRV or ductless mini-splits, depends on the unique demands of each industrial environment. Effective design and implementation, adhering to rigorous industry standards and providing BAS integration, are paramount to optimizing performance, ensuring regulatory compliance and supporting the critical processes that drive industrial operations.