A chiller energy optimization system can control multiple plants that are connected together A chiller energy optimization system can provide control optimization not just of a single plant, but can help optimize the combined operation of multiple plants that are interconnected.

A chiller energy optimization system can provide control optimization not just of a single plant, but can help optimize the combined operation of multiple plants that are interconnected.

There are two unique aspects of operating multiple plants “as one”:

- Coordination required on the chilled water distribution and pumping.

- Ensuring the chillers in both plants load evenly in chilling capacity.

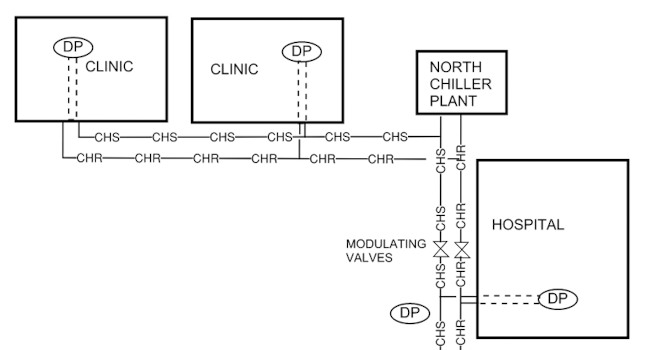

The chilled water pumps will still control to a delta P setpoint but there are multiple setpoints at the air handling units in the various buildings. There are also multiple pumps from each plant, now simultaneously trying to meet those setpoints.

The chillers in the plants also need to load evenly in capacity, which means the chilled water return temperature to each plant needs to be as close as possible (to avoid one chiller plant with a delta T of 5°F and another plant with a delta T of 15°F across the chillers).

The ability of a chiller to monitor multiple delta P settings as well as know the CWRT at each plant enables the chiller to constantly adjust delta P setpoints to direct the chilled water back to the plants to maintain, as closely as possible, even loading on the plants.

In Figure 5, the north and south chiller plants feed into the same campus distribution system. The chiller can adjust pump speeds and start/stop chillers in each plant to best meet the load at the lowest kilowatt/ton. For example, the chiller might operate two chillers from each plant, adjust the delta P setpoints and modulate the valves so that the clinic and hospital buildings are served by the north and south plants, respectively. Alternately, at low load, the chiller may dictate a single plant to serve the entire campus.