As electrification reshapes the hydronic heating landscape, engineers and facility owners must carefully evaluate whether traditional boilers or modern heat pumps best suit their building’s needs.

Learning Objectives:

- Differentiate between boiler types and heat pump systems in terms of efficiency, operational constraints, infrastructure requirements and suitability for various facility types and climates.

- Analyze the impact of electrification mandates and sustainability goals on heating system selection.

- Apply a structured decision-making framework to assess heating system options using real-world criteria.

Heating insights:

- The push for electrification has made heat pumps a popular heating option over traditional boilers.

- Boilers, air-to-water heat pumps and water-to-water heat pumps can all serve as the heat source in a hydronic system.

- The right hydronic heating system reflects the specific needs of the facility, the local climate and infrastructure constraints.

The hydronic heating landscape is rapidly evolving. As electrification movements gain ground across the United States, engineers and facility owners are facing increased pressure to adapt and, potentially, move away from boiler systems to heat pumps. However, this move comes with complications, and each system has unique capabilities, constraints and infrastructure implications to consider.

What is hydronic heating?

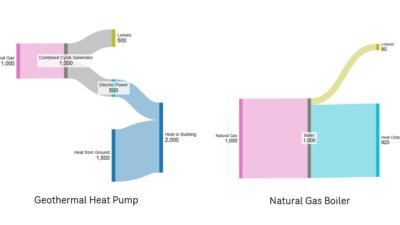

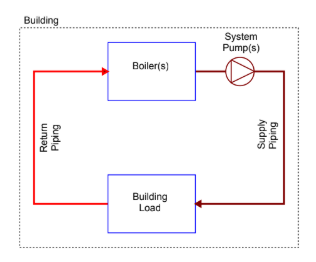

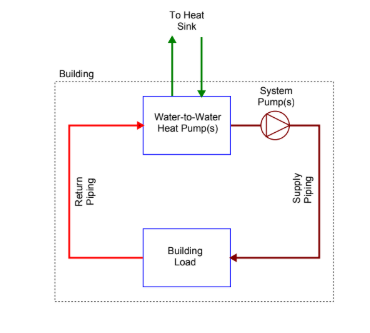

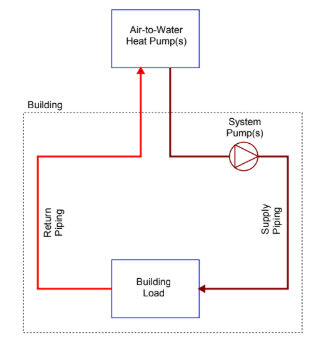

Hydronic heating systems use water as a heat transfer medium to circulate heat throughout a building. At the center of each hydronic system is a heat source, traditionally a boiler, that heats the water, which is then distributed throughout a building through piping to heat emitters, such as coils or radiators. After delivering heat to these emitters, the lower temperature water returns to the heat source to be reheated in a closed-loop process. Where boilers use a fuel source to generate heat (natural gas, fuel oil, electricity, etc.), heat pumps use electricity and vapor compression cycle (DX) to reject or draw heat to and from a heat sink.

Boilers, air-to-water heat pumps and water-to-water heat pumps can all serve as the heat source in a hydronic system. Each has different mechanisms, infrastructure needs and suitability depending on climate, facility type and utility constraints.

Simply defined:

- A boiler is a sealed pressure vessel that uses fuel or electricity to heat water or other fluids, delivering steam or hot water for heating, humidification or other applications.

- A water-to-water heat pump uses a heat sink to reject or draw heat. Typically, these are configured with a geothermal field of some nature (bore field, lake coil loops, etc.) to provide heated water for building heating.

- An air-to-water heat pump is an electrified component that uses the exterior air as a heat sink to reject or draw heat to provide heated water for building heating.

While in most heat pump configurations, the systems take advantage of simultaneous heating and cooling loads to produce both hot and chilled water, the chilled water side, or cooling modes, of the system will not be discussed in detail in this article.

The electrification push

There is a growing push for facility owners and design teams to adopt electrified systems to reduce a facility’s carbon footprint by eliminating combustion-based systems. Combustion can essentially be defined as the burning of some kind of fuel. States like California and New York have enacted laws prohibiting new fuel-fired equipment in buildings. More jurisdictions are expected to follow, pushing toward the American Institute of Architects’ 2030 net-zero carbon goals. This push is significant because the most common non-residential heating system in the U.S. is currently a boiler, with most utilizing combustion or fuel-fired processes to heat water.

Electrification is also not without complications. Most electric grids in the U.S. are not robust enough to support a large-scale move to electrified systems. To meet trending electrification mandates, it is likely that large facilities, such as hospitals, will need to construct their own dedicated substations in order to support the full-scale switching of heating systems to electric. Without proactive federal infrastructure upgrades, electric power demand could overwhelm local utilities, especially in winter when heat loads peak.

Moreover, defining “net zero carbon” requires nuance. Most mandates focus on achieving site-level carbon neutrality rather than total lifecycle emissions, meaning that regulations monitor the carbon emissions of a particular project site but not the entire facility or campus. Under this site-level carbon neutrality focus, it is likely that facilities that install electric heat pumps, while eliminating on-site combustion, may still utilize electricity that is generated from fossil fuels elsewhere in the facility footprint, complicating the environmental benefit of electrification.

With this in mind, electrification does not offer a “one size fits all” solution but rather requires engineers and owners to assess all heating and cooling options to determine how best to incorporate electrification into a facility’s existing infrastructure.

Boilers: A trusted mainstay

When considering heating options, boilers are the traditional choice, serving as a mainstay for many hydronic systems, especially in colder climates or mission-critical facilities.

There are three primary types of boilers to consider, categorized by efficiency and construction:

- Standard efficiency boilers (<84% efficiency): Rarely used today except in retrofits, standard efficiency boilers require high return water temperatures and are sensitive to condensing conditions, which can damage components. The pressure vessel and heat exchanger are constructed of carbon steel. Carbon steel is susceptible to thermal shock, stress cracking and corrosion from condensation within the heat exchanger. Also, flue piping is typically Category III for standard efficiency boilers.

- Semi-condensing boilers (85–94% efficiency): Often considered a cost-effective middle ground, semi-condensing boilers provide moderate efficiency improvements by capturing some heat from flue gases without the full material upgrades of condensing boilers. These boilers are typically a carbon steel pressure vessel with a stainless-steel heat exchanger. The stainless heat exchanger greatly reduces susceptibility to thermal shock stress. Flue piping will be Category I or III, depending on the specific boiler arrangements.

- Condensing boilers (>94% efficiency): Condensing boilers go a step further by capturing all the heat from exhaust gases, which goes uncaptured by other boiler types, significantly improving efficiency. This boiler type requires stainless steel construction due to the acidic condensate and often includes condensate neutralization systems, leading to a higher price point. A key advantage of condensing boilers, especially in cold climates, is sealed combustion, where air is pulled directly from outside to the boiler burner without the need for auxiliary heat sources to heat the boiler room and meet combustion air requirements. The ability for combustion air to be ducted directly to the burner (without pre-conditioning) is manufacturer-specific. The use of sealed combustion needs to be evaluated on each project and during any value engineering process. Flue piping will be Category IV in almost every case of condensing boilers.

- Electric boilers: This fourth option is utilized at a far lower rate than the three boiler types above. These typically involve some configuration of electric resistive or electrode type to heat water within a pressure vessel. Electric boilers are nearly 100% efficient with some power loss to radiant heat.

Air-to-water heat pumps: Electrification’s flagship

Air-to-water heat pumps utilize vapor compression cycles to extract heat from or reject heat to outdoor air, in order to warm a hydronic loop. While highly efficient in moderate climates, they do have operating limits in cold weather.

Key technical considerations include:

- Defrost mode: Air-to-water heat pumps can accumulate frost on their condenser coils in cold, humid conditions. Units must periodically reverse cycle to melt the ice, during which time heating is temporarily unavailable.

- Redundancy requirements: In critical applications, these units must be oversized or supplemented to maintain capacity during defrost cycles.

- Ambient limitations: Airside heat pump efficiency and capacity drop steeply below extreme outdoor temperatures, namely freezing weather. In such cases, they may be unsuitable without supplemental systems.

Additionally, glycol is typically required in airside heat pump loops to prevent freezing, which reduces heat transfer efficiency. Propylene glycol is preferred due to its low toxicity, but it still introduces a performance penalty compared to water.

Water-to-water heat pumps

Water-to-water heat pumps utilize stable ground or water source temperatures for efficient operation. These systems can perform seasonal heat exchange, sending excess heat to the ground in summer and extracting it in winter.

Advantages of water-to-water heat pumps include:

- High year-round efficiency: Because of its stable source temperatures, water-to-water heat pumps generally perform more consistently than air-to-water pumps.

- Scalability: Water-to-water heat pumps can be scaled effectively for large facilities or district energy systems.

- Design flexibility: Similar to air-to-water systems, these can be used with minor modifications, reducing project complexity.

If utilizing modular style heat pump systems, challenges involving water treatment and thermal fluid management are possible. In some modular systems, the building water (chilled and heating) can mix with the heat sink water as modules stage between heating and cooling modes. When this occurs, most equipment manufacturers call for equal water treatment and pressures in all three systems. This complicates water treatment and can degrade system efficiency.

A Practical example: Health care facility in Kansas City, Mo.

To illustrate the decision-making process, consider a hypothetical 250,000 square foot healthcare facility in Kansas City, Mo., which has a climate with both hot summers and cold winters. Based on ASHRAE 99.6% data, temperatures can drop below 24 degrees Fahrenheit, triggering code requirements for N+1 heating redundancy and on-site fuel storage.

Health care facilities in this region of the country can be as high as 40 British thermal units per square foot (BTU/SF) without domestic hot water generation. At 40 BTU/SF, the facility would need 10,000,000 BTU of heating capacity for space conditioning. There will be some differences in the required pumping head due to differences in equipment pressure drops and glycol content, but, for these examples, we will call that negligible. The physical space required for the pumps would also be equivalent and not used for comparison. To keep things equal, example systems are based on 145 F supply temperature and a 30-degree delta T.

Boiler configuration

For this example, three 6,000 MBH input condensing boilers would provide the N+1 redundancy required for the location. With an output of 5,700 MBH, the building load is covered with two boilers at full fire.

Boilers in the 6,000 MBH range have at least four manufacturers that can provide dual fuel options. Boiler efficiencies vary per manufacturer, but with 115 F return water, the best approximate efficiency would be 91.5%. Typical control strategies employ a supply water reset sequence that would lower the water temperatures, which would increase the efficiency in the full condensing range during off-peak seasons.

The electrical demands on dual-fuel boiler systems are minimal when compared to electric boilers or heat pump configurations. In the condensing boilers example, the burner load is roughly 8 KW per boiler, which, when applied to an emergency generator, will not greatly affect the final equipment sizing.

The electric boiler would directly affect generator sizing, with each equivalent boiler being 1680 KW. There are far more options for output capacity with electric boilers. The exact demand of the building could be met. However, for this comparison, an equivalent output capacity to the condensing boilers is being used.

At the rated output capacity, one boiler would use approximately 58 gallons per hour of fuel oil. Providing 24 hours of onsite fuel storage would require 2,800 gallons. In comparison, if pure electric boilers (1,680 KW each) were to be provided, the additional generator load would require 6,145 gallons of fuel storage for the same 24 hours of operation.

For reference, if 1476 KW (5036 MBH) electric boilers are used, then the fuel storage would be 5,400 gallons. In all cases, fuel storage is being provided in consumption usage, not tank sizing criteria per NFPA.

All generator fuel consumption calculations use a 32% efficient generator with an average heating value for fuel oil number 2. The three 6,000 MBH boilers require approximately 1,000 square feet of space within the building.

Air-to-water heat pump configuration

For this example, a modular heat pump arrangement was used. Each module has a max heating capacity of roughly 540 MBH. Four modules can be combined into a common unit from the factory (the exact capacity of module arrangements will vary depending on the manufacturer). The four-module unit has just over 2,000 MBH of heating capacity, meaning that it would require six total 2,000 MBH units to meet the 10,000 MBH load with N+1 redundancy. Note that this assumes the N+1 redundancy is not a single module but an entire unit. Discussions with the project owner would be needed to determine if a single additional module would meet their redundancy requirements.

Depending on the operating mode and exact ambient conditions of the systems, the Coefficient of Performance (COP), which is rated capacity MBH divided by input power in KW, can be as high as 5.42.

Each unit requires 138.4 KW of power, which would total to 692 KW with five units in operation for the load. The fuel storage requirements to cover the same 24 hours as the boiler example would be approximately 1,300 gallons. Each heat pump unit is 192 inches by 88 inches. Six units spaced per the manufacturer’s recommendations would require 1,500 square feet of exterior space with clear sky.

The ambient temperature operating range at the desired supply water temperatures is from 22 F to 98 F. The system can operate at lower ambient temperatures, but the relative supply water temperature must decrease.

While the electrical demands are not as substantial as an electric boiler, and the fuel storage requirements are less than a condensing boiler, the limited operational range at the desired temperatures would decrease the applications for which air-to-water heat pumps can be supplied. For this example, the inability of the air-to-water heat pump to provide the desired supply water temperature at the design ambient conditions would require supplemental heating when the ambient conditions are lower than 22 F.

Water-to-water heat pump configuration:

For water-to-water heat pumps, the most common arrangement is a modular string configuration, consisting of multiple modules that form a single unit. One manufacturer offers modules ranging from 180 MBH to approximately 2,000 MBH. A total of five modules would be required to meet the 10,000 MBH load, with a sixth needed for N+1 redundancy. Modules can be strung together into larger units. For this example, two units of three modules each will be used.

The simultaneous heating and cooling operation of the heat pump for this example can have a COP as high as 5.7. The input power required for the five modules for the load is 910 KW. The fuel storage requirements to cover the same 24 hours as the boiler example would be approximately 1,700 gallons. Each three-module unit is 100 inches by 160 inches. Maintaining the manufacturer’s required clearances of a total of 525 square feet of interior space would be required for both units. Note this does not account for the area required for the heat sink.

Without the limitations of the ambient conditions of the air-to-water heat pump, the water-to-water system has a higher COP (greater efficiency) and can operate across the entire range of ambient conditions. Water-to-water heat pumps are typically smaller in footprint when compared to dual-fuel condensing boilers.

Selecting the right system

When considering which heating system is right for a facility, owners and engineers should ask themselves the following questions:

- What is the facility’s occupancy type and criticality? Mission-critical (e.g., hospitals) often favor boilers with backup systems due to their reliable nature. Offices or retail may tolerate greater temperature fluctuations, making heat pumps viable.

- What are the local climate conditions? Sub-zero climates may limit airside heat pump effectiveness.

- Does the criticality of the facility necessitate the design to accommodate a backup heating source from a fuel source (e.g., gas, fuel oil, propane, solid fuel)? Water-to-water systems can be cost-prohibitive in areas with deep permafrost or sites with limited borehole access.

- What energy sources are available and stable? Natural gas availability and pricing may favor boilers. Utility incentives or stable electrical rates may support electrification. If a commodity-based fuel source, like propane, is the only option, then electrification may be beneficial to avoid seasonal price fluctuations associated with the commodity.

- Is the electrical infrastructure sufficient? Electrified heating requires substantial grid capacity and may require a facility to enhance its power grid. If code or project requirements necessitate that heating systems operate even in utility failure, then the emergency systems, generators, and fuel source must be sized to accommodate the heating demands.

- What is the owner’s philosophy on sustainability and payback? Long-term owners (e.g., public institutions) may accept longer life-cycle cost analysis paybacks for electrification. Developers may prioritize first cost and code compliance.

- What is an ideal operating water temperature? Lower water temperatures will increase condensing boiler efficiency. They may require larger heating coils to compensate for the thermal heat transfer coefficient. Supply water temperatures below 130 F can lead to three- and four-row heating coils increasing air pressure drop and fan energy usage. Supply water temperatures below 145 F will not allow for domestic hot water generation at 140 F. Alternate source(s) for domestic hot water generation would be required under 145 F. Lower water temperatures will increase efficiency of air-to-water heat pumps, but can cause operational issues at very low ambient temperatures.

If we apply the questions presented to our example project above, we can see that while air-to-water heat pumps are still a valid option, the need for the supplemental heating could turn into a cost prohibitive option. Traditionally, most healthcare applications default to boiler plants, but if the owner has electrification initiatives and/or the onsite land to accommodate a heat sink, the water-to-water heat pumps could be applicable option. However, there would still be questions on domestic hot water generation.

No universal option

Heat pumps are not a universal replacement for boilers, nor are boilers obsolete in the face of electrification. The right system reflects the specific needs of the facility, the local climate and infrastructure constraints. While there is no one-size-fits-all solution, asking the right questions can help reveal the best solution for a particular facility.

Whether designing for net-zero goals or simply seeking a reliable system, the decision between boilers and heat pumps deserves careful evaluation. At the end of the day, it is not a decision that can be made from an HVAC perspective alone, but rather from the perspective of a facility’s entire infrastructure and expected life/usage.