Generator sizing software can help engineers optimize emergency system designs for various load types.

Mission critical facilities, such as hospitals, data centers, financial institutions, and other data processing facilities, are required to protect against possible failures of normal electric utility power sources and provide a reliable alternate supply of power. Engine-driven generators are the workhorses that fulfill this need for emergency and standby power. With critical operations—and many times, human life—relying on these systems, it is important for the engineer to design an emergency system that is sized correctly for the various types of loads. If a generator system is undersized, it will cause voltage fluctuations and damage to the generator or equipment it serves, or worse, lose the load entirely. If it is oversized, it may develop maintenance problems and other issues such as wet stacking.

The most common method for sizing a generator system is total connected load. However, there are various other factors, such as altitude, temperature, fuel type, and application, that influence generator sizing. In today’s mission critical facilities, there are also number of different types of loads, such as fire pumps, chillers, and UPS systems connected to an emergency/standby power system, that can impact the generator size. Each of these load types has a different characteristic during start-up and run time, and reacts differently under various electrical anomalies. Some load types, such as fire pumps, have specific voltage drop (less than 15%) or frequency dip requirements that must be met during start-up. These factors must be considered and analyzed when sizing a generator.

A detailed analysis of the load and sizing parameters to manually size a generator can be a daunting task. However, sophisticated software is available to assist the designer in sizing and selecting the correct engine. Generator sizing software programs in today’s marketplace are intricately developed to allow for a precise selection that is specifically catered to each application.

To take an in-depth look at their characteristics, this article presents a hypothetical project using four popular sizing software programs. The case study includes predefined load parameters and includes tips and techniques to optimize the generator size.

Example project

For this example, consider a facility that requires a standby diesel genset to support various loads (see Figure 1). For these loads, assume that the system can tolerate a maximum of 35% voltage dip and 10% frequency dip. The loads that the genset must support are listed in Table 1.

Cummins Power Suite 5.0 GenSize

Cummins Power Suite 5.0 GenSize is a software program developed by Cummins Power Generation, Inc. According to developers, the goal of the program was to have a tool that is easy to use, yet very flexible. The program allows users to input specific parameters, such as voltage drop of motor loads, which allows for maximum flexibility. The program also includes default parameters that help ensure the designer does not undersize a generator. In addition, on each page, it includes page-specific help tools that include tips and direct links for contacting the local distributor. The software is available as an online database that allows the developers to provide current performance data, which is updated regularly to ensure the user is not using obsolete data. Cummins Power Suite GenSize includes an online tool that allows collaborative work in which projects can be shared on the online dashboard among designers or application engineers. The data are not visible to any other user unless the project is specifically shared on the collaboration site. The program is not available in a downloadable version, but projects that have been initiated in earlier versions of the downloadable version can be uploaded to the site.

The example project load data was entered into the program based on a number of available presets (see Table 2). The loads were then assigned to the quantity of steps applicable to the project. After the data are entered and the steps are assigned, the software first selects the smallest genset that meets the performance requirements. For the example project, the software recommended a single 1,500 kW/1,875 kVA genset. In addition to this selection, the program provided alternate selections of generators that may meet the needs and highlights parameters that won’t meet the entered requirements. The program highlights the parameters in two different colors: red if it won’t meet the requirements, and yellow if there are some cautionary items the designer should consider. This feature helps the user understand exactly what is driving the size of the engine and provides guidance on some design changes that could be made to reduce the system size. On the results page, the specification sheets are directly linked to the system-selected engine as well as building information modeling (BIM) results. There are several print features available directly from the results page as well.

Caterpillar Electric Power SpecSizer

SpecSizer is a software program developed by Caterpillar, Inc. It is currently available as a downloadable program from the Caterpillar website, and the software resides on each individual computer. According to developers, the system will be available as an online program by the end of 2013. The program allows users to enter specific parameters, such as percentage of intermittent motor starts, which allows the designer to account for real-world operating conditions when working with systems that have a large quantity of motors. Other features expected in the online version include a specific chiller load parameter, which will help system designers model chiller loads more accurately than the currently available ac load feature.

The load data from the example project was entered into the program based on the available predetermined loads (see Table 1). As the loads are added, the software displays an up-to-date report of the connected load on the load scenario screen. The loads are assigned a step when the load is entered. After the data are entered and the loads are assigned, the program generates a selection based on the smallest generator that will meet the performance requirements.

For the example project, the software indicated that “no standard SINGLE genset is large enough under the specified site conditions. Sizing will continue by paralleling the minimum number of generator sets necessary.” The software recommended four 550 kW/687.5 kVA paralleled units. The initial results were unexpected because Caterpillar offers larger size engines. After further discussion with the software expert, it was discovered that SpecSizer offers three different input parameters for the genset duty. If emergency standby is selected—as opposed to standby or standby/ESP—the program limits the selection to a very narrow rating category that isn’t applicable here. The software expert indicated that this will not even be an option in the next revision of the software.

After the correct engine duty was selected, the software recommended one 2,000 kW/2,500 kVA genset. Under the technical section of the software, the program generates project sizing reports and provides a transient performance report showing the true characteristics to be expected per step. The software also provides links where the user can download the spec sheets or go directly to the website. BIM models are currently not available directly through links from the software. However, drawings and other application data are provided.

Generac Power Design Pro

Power Design Pro is a software program developed by Generac Power Systems, Inc. The software can be downloaded from the Generac website to an individual computer. After the registration process, program operation begins with the project setup. This software includes very thorough data preset options, such as NEC application, enclosure types, fuel tank options, and run time. A user settings tab offers overall parameter data input for future project use if desired. The software also offers downloadable material from the start-up page including specifications, spec sheets, installation instructions, and an engine emissions certificate for the recommended genset.

After the project setup is complete, the user adds loads from the predetermined load menu. This software offers the largest selection of load options compared to the other programs (see Table 2). After the load data are entered, the loads are assigned to either a group (non-concurrent load) or a step (concurrent load). The load summary page is continually updated with the recommended generators as loads and steps are added.

A unique feature of Power Design Pro is the ability to manually select the generator. Instead of using an autoselect function, the designer may input a specific kW rating and configuration. For the example project, after the loads were entered under the autoselect function, the program recommended six 500 kW/625 kVA paralleled generators. When switched to the manual function, and 600 kW units were selected (the maximum kW rating offered by Generac), the program recommended three 600 kW/750 kVA units. Although it wasn’t recommended by the autoselect function, alternate quantities and sizes of generators were allowed to be selected that still met the project parameters. If a system that will not meet the parameters is selected, the entries are highlighted in red indicating that the manual selection would not meet the project parameters. This is a very flexible option for the program, allowing the engineer to determine the quantity and size of the generators for each specific application. Although the program does not appear to automatically select the lowest quantity and kW rating that can be used, the flexibility is a benefit.

After the generator system has been selected, the mechanical design tab assists with gas and exhaust piping layout and paralleled generator configuration. The analysis tab provides direct access to several reports including a project summary and transient and harmonic analyses.

Kohler QuickSize

QuickSize is a software program developed by Kohler Power Systems. It is an easy-to-use, Web-based application that requires a login and password from a local distributor. The login information is the same for each member of a company for easy file sharing. All projects developed using this software are automatically available to the Kohler representative and can be viewed if additional help is desired. Specification sheets and other PDF drawings are available through the site. However, CAD drawings and BIM models must be requested through a representative. After running through the sizing software, a custom specification is available (as a Word document) for the project based on the parameters and genset selected. The specification can be used as a whole, or copied and pasted into another specification format to suit the user’s needs. Similar to the other programs, QuickSize uses preset pull-down buttons for entering parameters, which can be revised during any step of data entry. All of the information is shown on one screen, and all of the data can be changed at any time.

First, the load steps are entered, and then specific loads are added. The loads can be moved up or down between the steps at any time, and all information is easily editable throughout the process. After all data are entered and load steps are assigned, a click of the search result button yields a list of applicable gensets, listed by model number, alternator, and engine with the smallest recommended size at the top. Engines that will not meet the requirements are indicated in red at the bottom with an explanation for the program’s rejection. For the example project, the software recommended a single 1,500 kW/1,875 kVA generator. From here, a direct link to a summary report of all the inputs and other parameters used is available, and specifications may be created.

Kohler indicated it will continue to develop its software program to provide the necessary tools and options to enhance the user’s experience by making the program comprehensive and intuitive.

Strategies for optimizing system selection

After initial project data are entered into the system, there are several tips and tricks for reducing the required system size. A partial list of tips includes:

- Provide higher quality rectifiers on equipment to reduce harmonics.

- Include VFDs or reduced voltage starters on motor loads to allow soft starting and minimize the starting impact.

- Allow for additional load steps on the project by adding automatic transfer switches, programmable logic controllers, or time delays.

- Load the system with the largest motor loads first.

- Disable capacitors on emergency loads.

- Include a UPS upstream of medical imaging or other sensitive loads to reduce their voltage and frequency dip requirements.

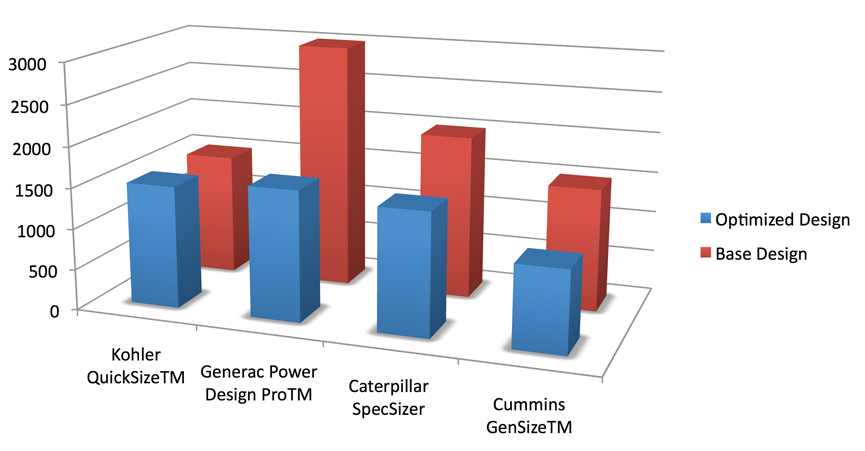

Applying some of these changes in the design can have a huge impact on the generator size. These items may also be higher in cost, but if the results reduce a generator size or even the quantity of generators required for the project, it may provide significant financial benefits to the project as a whole. In the example project, a few of these elements were applied to the loads as shown in Figure 2 with the results shown in Figure 3.

Results analysis

As illustrated in the analysis, each software program yields different results. Each manufacturer has a unique way of modeling the load parameters with built-in baseline defaults. The only defaults changed for the example project are those called for in the example project description.

In addition, each program models the operating functions of the gensets differently. For example, when calculating the sustained voltage dip for the project parameters, some programs use an average voltage dip over several cycles while others use an instantaneous voltage dip. Also, some manufacturers use their own alternators while others purchase outside alternators. Therefore, the internal modeling differs because of the inherent properties in the equipment.

The most important factor in using generator sizing software is to know as much as possible about the loads and remember that sometimes it can be more of an art than a science. The more exact the data input—as opposed to using the system default parameters—the more accurate the required generator size will be. Using a generator sizing program properly will provide the designer with a higher level of confidence for specifying a system that is large enough to meet the project needs, but not oversized. However, even with sophisticated software solutions, the designer must use his or her engineering judgment in selecting the proper genset size.

Danna Jensen is associate principal at ccrd in Dallas. With 13 years of electrical engineering experience, most of her work consists of designing electrical distribution systems for hospitals; however, she also designs electrical systems for office and retail facilities. Jensen was a 2009 Consulting-Specifying Engineer 40 Under 40 winner and is a member of the Consulting-Specifying Engineer Editorial Advisory Board.

Abby Lipperman has 8 years of electrical engineering experience with ccrd in Dallas. Her primary project experience is in the health care industry, but she is also involved in many different project types including data centers, technology labs, museums, schools, banks, and commercial and office spaces. Lipperman was also a Consulting-Specifying Engineer 40 Under 40 winner in 2009.