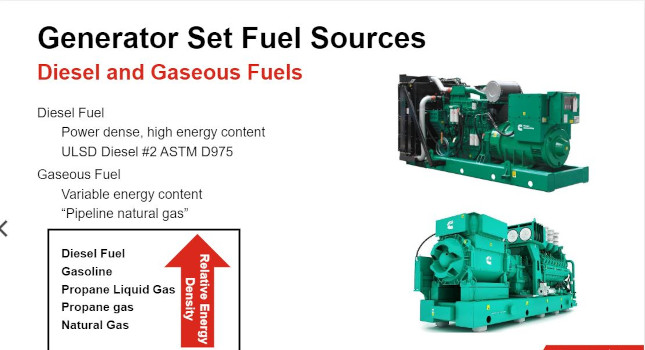

Learn about the applications of and building code considerations for specifying generator fuel sources

The installation of gaseous generator sets in a wide variety of building types continues to rise in North America while facility performance requirements, codes and standards are often most closely linked to their traditional diesel counterpart.

As natural gas- and propane-fueled generator sets reach the market with “diesel-like” performance, it’s critical to understand how best to and specify these products to maximize the value they provide.

Below are answers to questions not addressed in the webcast on Thursday, May 20, 2021.

Learn more from Mark Taylor, Technical Marketing Advisor, Cummins Inc.:

What are the best applications for gaseous gensets?

Anywhere gas is available! As the presentation covered, there may be a bit more work with the utility and authority having jurisdiction for life-safety loads for utility-only fueling. Gaseous-fueled generators are great for customers who express a strong disinterest with diesel fuel maintenance.

Some manufactures account for parasitic loads in their name plate. Does Cummins?

Cummins does account for all typical parasitics when listing its ratings, not least of which being engine-driven set-mounted cooling systems, battery charging alternators, etc. This is in practice with the expectations of ISO 8528-1. Further, Cummins ratings are guaranteed, where we understand product to product variation and we ensure each product produces its nameplate rating with full load testing at the factory.

The Center for Medicare & Medicaid Services still follows NFPA 99-2012, which references 2011 edition of NFPA 70: National Electrical Code and 2010 NFPA 110. Have you had any experience with a hospital being allowed to use natural gas as a primary fuel source?

Cummins does have experience with natural gas fueled generators in hospital settings. One great example: In hurricane-prone Louisiana, a hospital utilized the strength of diversity by using both diesel and gas.

What is the typical amount of time it takes for a diesel or natural gas generator to start and signal theautomatic transfer switch it is ready to accept load?

Cummins generator sets that cite compliance to NFPA 110 Type 10 will typically reach “ready-to-load” (90% of rated frequency and voltage) within 6 to 8.5 seconds of receiving the start signal. That should allow for the other components in an emergency power supply system to do their jobs for meeting 10 seconds for the entire EPSS.

What generator sizing programs does Cummins offer? I’ve used Power Suite, but I thought you just mentioned a different software program toward the end of the presentation.

Cummins Power Suite is the name of the website where our sizing software exists (as well as our sample specs, and library of data sheets and application manuals!). GenSize is the sizing tool within Power Suite; apologies if I caused any confusion!

How do I size a liquid propane tank?

For vapor withdrawal, the foremost consideration I would mention is to ensure the tank is sized so that the generator’s full load fuel consumption can be matched by the vaporization rate of the fuel in the tank at worst case (coldest) ambient temperatures. If a tank is undersized, there is a risk of starving the engine of fuel. So don’t simply size a vapor withdrawal tank to simply meet NFPA 110 Class, but rather, meet the class AND be able to withdrawal enough fuel. For much more info, I recommend section 6.6.9 in the T-030 Manual, free on Power Suite.

Is it true that gaseous gen set are typically up to 250 kilowatts?

Gaseous generator sets cover a very wide range of power nodes. For example: Cummins offers products up to 1.3 MWe that are suitable for NFPA 110 Type 10 applications; and products up to 2 MWe that are > Type 10 starting times. Check out Powersuite.cummins.com to see the product pages or talk with your local Cummins representative to learn more.

Is there a reasonable process to get utility-provided natural gas recognized as “on-site fuel”?

Generally speaking, the process is one that involves a conversation between the design engineer, the utility and the AHJ. This can be accomplished at time with an uptime report or letter from the utility for the AHJ to reference. “Reasonable” may be subject to the particular individuals involved and their interpretation of the codes, but if there is any need for support in these conversations, please give your local generator set manufacturer representative a call.

Do you do inductive load testing other than resistive load test?

Inductive load bank testing is done for our generator sets at our factory during prototype testing and factory acceptance testing. We generally test to 0.8 lagging and 1.0 unity power factors. Generally speaking, for site commissioning we recommend resistive load bank testing due to the costs of inductive load banks.

What do you do to the diesel fuel if it’s not been used after 12 to 16 months?

Inspect it with a proper fuel analysis. NFPA 110 stipulates yearly testing to ensure fuel is in acceptable condition. A customer’s fuel supplier very likely has inspection services, but so does Cummins! If you’re interested in our services, you can reach out to your local rep. Here is a brochure as well.

Does the utility gas company supply the natural gas via electric pumps? What if power is loss and the backup generator rely on a constant supply of natural gas? Will the supply from utility stop if there is a brownout?

It is common for gas pipelines to be pressurized by equipment fueled by the gas in the pipeline itself. I’d refer you to this informative article by American Gas Association for more info.

Is liquefied natural gas a viable fuel choice?

Liquefied natural gas is primarily used for “prime” or “base load” operations where there is no natural gas network, such as remote mine sites and islands. In the liquid form, natural gas has the benefit of being the most compact for transportation to such locations. However, liquid NG must be very cold, and only stored at low pressure with insulated tanks for short to medium term time durations, so it’s generally not ideal for standby applications as it’ll eventually boil away. Propane, however, can be stored indefinitely at pressure.

Does a filtered fuel recirculation system for a stored diesel fuel supply system for a diesel engine driven generator set help maintain fuel quality? A system that removes condensation and the possibility of microbial growth.

Such a system will help extend the life of fuel, and a built-on polishing system on the fuel tank is something we’ve seen when end-users do not want to deal with the hassle of bringing in polishing services. That being said, still inspect the fuel with a fuel sample and analysis in keeping of NFPA 110’s requirements.

Are there any special considerations of fuel for paralleled gensets?

The fuel (e.g., diesel fueled or gaseous fueled) should have no impact on paralleling generators. The key factors in paralleling generators are more alternator-centric: such as phase angle, waveform based on the alternator windings, frequency and voltage. If you’d like to learn more about genset-based paralleling, I encourage you to check out our webinar on the topic.

Do you maintain that gaseous generator sets can accept large block loads as efficiently as diesel gensets?

There are many gaseous-fueled generators that are just as good at picking up large block loads as their diesel-fueled peers. Gaseous fueled generators have seen consistent investment by manufacturers and new products are pushing beyond old notions of what these products can do. I encourage anyone to check out the product’s performance on generator set sizing tools for your project’s needs. (There do exist gaseous-fueled generators that are designed primarily for highly efficient, continuous-duty usage (e.g., combined heat and power, greenhouse applications, etc.) where it makes it very hard to make a blanket statement on standby performance for ALL gaseous products.)

Is annual fuel polishing only required for legally required diesel back up power systems per NFPA 110?

To clarify, fuel polishing should be done as needed based on the results of (at least) yearly inspection and testing of the fuel. To my understanding looking at Chapter 8 of NFPA 110, this is a generic expectation for maintaining system reliability. Also note manufacturers may have specific recommendations as well.

Please explain the difference between liquid propane and gaseous propane for gensets.

Ultimately, the engine will be running on propane in the gaseous form. How liquid propane gets to the gas form is usually what is being described by “liquid withdrawal” or “vapor withdrawal.” Withdrawal, in this case, is from the perspective of the propane tank itself. With vapor withdrawal, the fuel is vaporizing within the tank and the fuel is pulled from the top of the tank. With liquid withdrawal, fuel is drawn from the bottom of the fuel tank, but it needs to be vaporized somewhere before being ingested by the engine. That is where devices called vaporizers come into play. These can be a part of the gas system between the tank and the generator set. Vapor withdrawal is generally a simpler approach but may take up more space. Work with Cummins and/or your tank provider for help in choosing the best fit for you needs.

Is there a Tier 4 diesel standby generator with Cummins?

Yes, there is! We offer factory-certified stationary nonemergency products (i.e., Tier 4) for both standby and prime duty cycles. I recommend reaching out to your local sales person to learn more!