Ensuring adequate backup power is crucial for safeguarding personnel safety and enhancing the resilience of facility operations during interruptions.

Learning objectives:

- Differentiate between emergency, legally required and optional standby systems.

- Recognize the available sources for backup power systems.

- Understand the basic installation requirements for each type of power system.

Backup power insights:

- Emergency power systems have the most stringent requirements compared to legally required or optional standby systems.

- Identifying which local and national codes apply to each system will allow engineers to design the best power source for each project.

Backup power ensures a supply of electricity is provided during a utility failure. While backup power comes in many forms and with various terms and definitions, there are particular types of backup power defined by NFPA 70: National Electrical Code (NEC). The key question is: what do I need the backup power for? Is it for life safety, is it legally required by code or the authority having jurisdiction (AHJ) or is it a standby to prevent loss of productivity in the absence of normal or utility power?

Backup power sources can be a reciprocal engine, or engine-driven generator, which can use diesel or gaseous vapor fuels. Other sources include stored-energy systems, which come in different types and technologies. This article will discuss different types of backup power systems and their applications, appropriate power sources and design considerations/best practices.

Codes and standards for backup power systems

Important codes and standards for backup power include:

- NFPA 70: National Electrical Code

- NFPA 70E: Standard for Electrical Safety in the Workplace

- NFPA 101: Life Safety Code

- NFPA 110: Standard for Emergency and Standby Power Systems

- International Building Code (IBC)

- International Mechanical Code

- International Fire Code (IFC)

- National Electrical Manufacturers Association

The NEC defines three types of backup power systems: emergency systems (Article 700), legally required standby systems (Article 701) and optional standby systems (Article 702). Additionally, NFPA 110 discusses emergency and standby power systems, but does not discuss optional standby systems.

Emergency/life safety systems

“Emergency” or “life safety” systems are the most critical type of system that can be installed within a facility. These systems are specifically designed to protect the life and safety of personnel.

The NEC defines emergency systems as “systems legally required and classed as emergency by municipal, state, federal or other codes, or by any governmental agency having jurisdiction. These systems are intended to automatically supply illumination, power, or both, to designated areas and equipment in the event of failure of the normal supply or in the event of accident to elements of a system intended to supply, distribute and control power and illumination essential for safety to human life.”

NFPA 110 classifies emergency systems according to the system’s level of criticality. Emergency/life safety systems generally correspond to Level 1 systems in NFPA 110. This is defined as systems where “failure of the equipment to perform could result in loss of human life or serious injuries.” In addition to level, NFPA 110 also defines the system’s type (the maximum time that the emergency system is permitted to transfer power from the normal to the emergency source when the normal source fails) and the system’s class (the minimum number of hours that the emergency system is designed to operate without requiring refueling or recharging).

For example, a Type 10/Class 48 system is required to begin supplying emergency power within 10 seconds of the failure of the normal power source and have a minimum of 48 hours of fuel storage.

Legally required standby systems

The second type of backup power system is a legally required standby system.

The NEC defines legally required standby systems as “systems required and so classed as legally required standby by municipal, state, federal or other codes or by any governmental agency having jurisdiction. These systems are intended to automatically supply power to selected loads (other than those classed as emergency systems) in the event of failure of the normal source.” These systems do not include loads that are considered emergency and essential to the safety of human life.

Legally required standby systems also often correspond to “Level 2” systems, defined by NFPA 110 as systems “where failure of the emergency power standby system (EPSS) to perform is less critical to human life and safety.” Not all legally required standby system will be covered by NFPA 110. If the system does not play a role in the safety of human life, then NFPA 110 does not apply.

Optional standby systems

The last type of backup power system is the optional standby system.

The NEC defines optional standby systems as “systems intended to supply power to public or private facilities or property where life safety does not depend on the performance of the system.” Because optional standby systems do not supply life-safety loads, NFPA 110 does not apply to optional standby systems.

Application of emergency, legally required and optional standby systems

Often, the requirement for a backup power system is defined by standards other than the NEC or NFPA 110. One of the most common drivers for an emergency system is emergency lighting. Both the IBC and NFPA 101 have requirements for emergency lighting. IBC requires “an emergency electrical system (to) be provided to illuminate” certain areas (IBC 1008.3), while NFPA 101 mandates emergency lighting for means of egress be provided in a variety of types of buildings and requires “new emergency power systems for emergency lighting shall be at least Type 10, Class 1.5, Level 1, in accordance with NFPA 110,” (NFPA 110 7.9.2.2),” and corresponding to a system that can supply emergency power within 10 seconds for a minimum of 90 minutes.

Other drivers for the installation of backup power systems include requirements based on the facility type. For example, Virginia Sewage Collection and Treatment regulations require that, if a certain sewage pump station cannot be fed from two redundant transmission lines, then an auxiliary power source must be provided. This is a good example of a legally required standby system that is not an emergency system.

Other requirements for backup power systems may be driven by conditions such as the storage of hazardous materials. The IFC requires that where mechanical ventilation is required for hazardous materials, storage mechanical ventilation must be fed via an emergency or standby power system.

Additional requirements for backup power systems may be located in facility specific codes, such as NFPA 99: Health Care Facilities Code or other locally adopted codes.

Power Supply Sources

Backup power systems can use a variety of sources.

The NEC lists the following power sources for emergency systems:

- Generator sets: Engine-driven generator sets (i.e., diesel or natural gas generators).

- Stored-energy systems: Systems that store the required backup energy. Types of stored-energy systems are uninterruptible power systems, fuel cell systems, energy storage systems and storage batteries.

The most common type of power source for emergency and standby power systems is an engine-driven generator. Most generators are fueled by either diesel or gaseous vapor (natural gas, propane or liquified petroleum gas). The NEC requires that emergency and legally required standby systems have an on-site fuel supply of at least two hours and generally prohibits the use of municipal gas systems as the sole fuel source unless specifically approved by the AHJ.

The basic design requirements for emergency and standby systems are outlined in the NEC and NFPA 110. The engineer must do a complete code analysis to determine all applicable codes and standards for the design and select the appropriate backup power system type and requirements. This may include coordination with the owner, architect, mechanical engineer and process engineer.

Requirements for emergency systems

Emergency systems typically have the most stringent requirements. For instance, because of the critical nature of the loads, the wiring for the emergency system must be entirely separate from the wiring for the normal power system.

One of the major requirements for emergency systems is the separation of the emergency power supply (EPS) and EPSS equipment from other equipment and the rest of the building. For Level 1 systems, NFPA 110 requires that the EPS (i.e., the generator) must be located either in a dedicated room protected by a two-hour, fire-rated wall or located outside. Furthermore, in Level 1 systems, the EPSS (which includes the electrical system from the EPS up to and including the transfer equipment) cannot be installed in the same room as the normal electric service equipment when the normal service equipment is rated over 150 volts to ground and is greater than or equal to 1,000 amperes. These requirements apply to a large number of commercial buildings and are often met in one of two ways. Either the design includes a separate emergency power room or the generator and transfer equipment (i.e., the automatic transfer switch) are located outside the building.

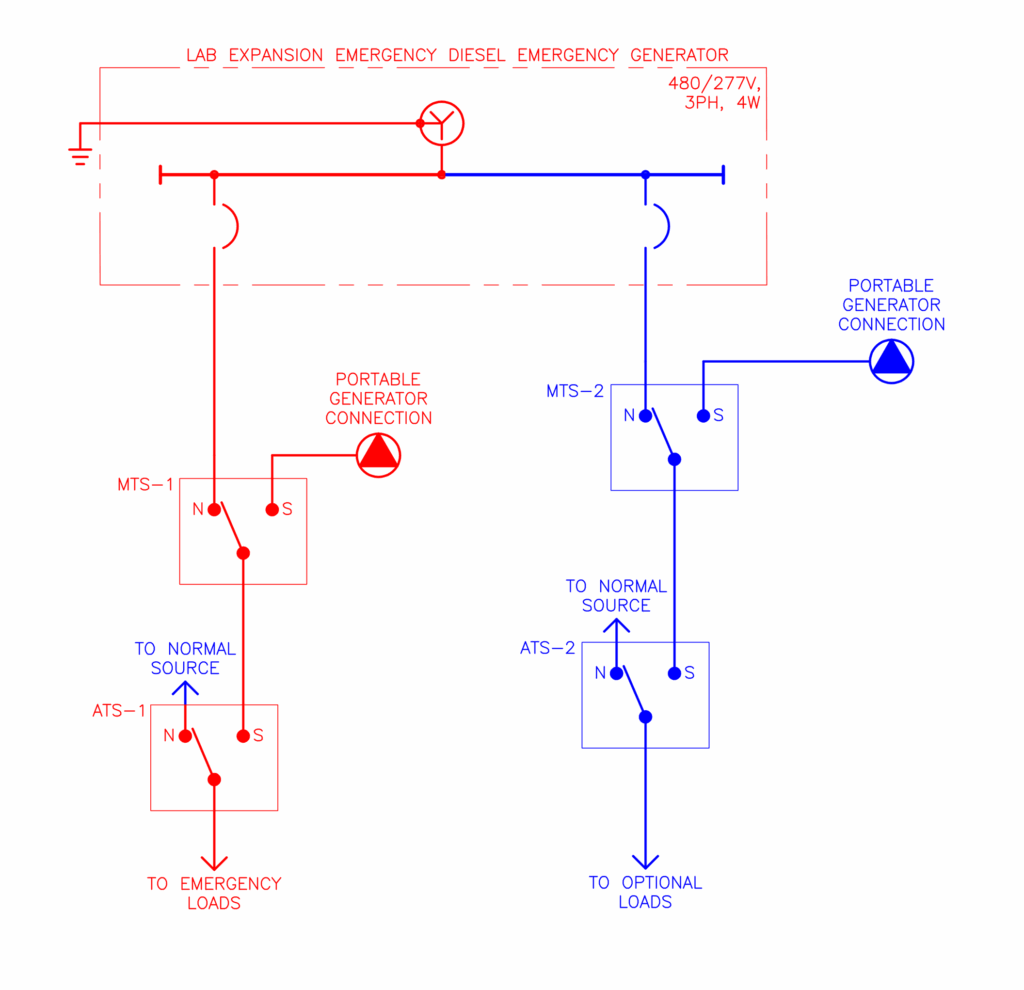

Power sources and generators for emergency systems can also feed legally required and optional standby systems, but the system must be designed with dedicated and separate circuit breakers from the EPS to feed the emergency and the legally required/optional. This is often implemented by installing multiple circuit breakers directly inside the generator enclosure. However, it is also permissible to have a switchboard or switchgear (including a main circuit breaker, if selectively coordinated) to distribute the power to the separate system circuit breakers (provided that each circuit breaker is in a separate vertical section). If the system supplies both emergency and legally required/optional systems, then the system must either be capable of carrying all loads or be provided with load management to ensure that optional legally required loads are shed and that power is available for the emergency loads.

As of 2024, an additional requirement in NFPA 110 for emergency/Level 1 systems is that generators used for Level 1 applications cannot be equipped with U.S. Environmental Protection Agency (EPA) mandated inducement engine shutdowns related to emissions systems. This essentially means that EPA stationary non-emergency/Tier 4 certified diesel generators can no longer be used for these systems. Additionally, based on this code change, the major diesel generator manufacturers have stopped producing Tier 4 certified diesel generators.

Requirements for legally required and optional systems

Generally, the requirements for legally required and optional systems are less stringent than those for emergency systems.

For example, the wiring for legally required and optional systems is permitted to be installed along with the normal wiring system. Because legally required and optional systems are not Level 1 systems, the requirement for a separate room or to locate the EPS/EPSS outdoors does not apply.

However, some requirements still apply. For example, legally required systems are still required to use listed and marked transfer equipment. Legally required systems must also still receive AHJ approval to use natural gas as the fuel source.

Other design considerations

In addition to conducting code analyses, determining the appropriate backup power size for the required loads and selecting the correct application, designers should consider the following:

- Maintenance and accessibility: Consider how staff will maintain the generator. If the generator does not sit directly on the ground (i.e., if a subbase fuel tank is provided), consider providing an access platform for ease of maintenance. The height of the generator from the ground/floor with a subbase fuel tank could pose a safety hazard for maintenance personnel. For emergency lighting using batteries, a centralized battery system with a testing mechanism is generally easier to maintain and periodically test compared to individual battery packs installed in high or hard-to-reach locations, such as on walls or ceilings.

- Environmental conditions: Ensure the generator is suitable for the environment in which it will be installed. This includes accounting for the mounting structure and protection from harsh weather conditions and storms. If heavy winds or storms are expected, consider installing the generator indoors with a plenum to protect the generator and the generator room.

- Fuel type and storage size: For non emergency generators, consult the owner about the preferred fuel type and storage quantity (generator run time). Determine how fuel will be delivered.

- Generator capacity: In general, it is recommended to design generators to not exceed 80% of their rated capacity. However, generators should also not be significantly oversized, particularly to prevent diesel generators from wet stacking. Additionally, consider whether any future expansion or new loads are expected.

- Noise mitigation: Consider the generator location and what the impact of the generator noise will be. Zoning requirements for noise may apply, but some zoning ordinances exclude emergency operations from the noise requirement. If noise is a concern, consider installing a sound-attenuated generator enclosure and/or implementing sound-mitigation techniques if the generator is located inside a building.

- Ventilation: If the backup power is located indoors, consider how the room will be ventilated. It is critical to ensure that air flows over the entire generator set (genset) and does not short-circuit past the alternator. For interior generators, a carbon monoxide detector is recommended and may be required by code.

- Sequence of operation: Consider how the generator will integrate with the electrical system. Loads may need to be “staged” to not exceed the generator starting capacity when loads are reconnected. Multiple automatic transfer switches may be required, or load-shedding switchgear can be used.

- Remote monitoring and testing: For some applications, remote monitoring of the generator is required by code. Consult the owner about remote monitoring methods and permissible locations. Remote monitoring will also aid periodic maintenance.

- Emergency shutdown: Generators greater than 15 kilowatts are required to have an emergency shutdown. Coordinate with the owner and/or the AHJ/fire department regarding the best and most logical location for the emergency shutdown switch.

- Periodic maintenance: Periodic testing and maintenance are critical for all generator applications, but only some generator applications require it. Consult the owner about the recommended maintenance schedule and consider including an automatic exercise timer to routinely run the generator to ensure generator readiness. NFPA 110 Chapter 8 contains requirements and recommendations for routine maintenance and operational testing.