The use of AI and other new technologies are changing the way industrial facilities operate. Understanding the trends will help engineers design efficient facilities.

Learning objectives

- Identify how automation is changing the manufacturing process and how this impacts design decisions.

- Understand sustainability goals and standards owners desire in their facilities.

Automation insights

- Increased automation is driving the efficiency of manufacturing processes, changing the focus of the building’s design.

- Standards like LEED, WELL and the Living Building Challenge require uniqe solutions that will work well throughout design and construction.

Respondents:

- Jason R. Gerke, PE, LEED AP BD+C, BCxP, Senior Design Phase Manage, JP Cullen, Milwaukee

- Jarron Gass, PE, CFPS, Fire Protection Discipline Leader, CDM Smith, Pittsburgh

- Matt Merli, PE, Principal / Client Services Director, Fitzemeyer & Tocci Associates, Inc., Woburn, Mass.

From your experience, what systems within industrial and manufacturing facilities are benefiting from automation that previously might not have?

Jason R. Gerke: There are many industrial facilities constructed that are not highly sophisticated buildings. These buildings may be big spaces to perform a set of tasks that have limited impact on air quality and minimal dehumidification needs. Designing buildings that may be a more straightforward configuration still allows for a level of HVAC controls to monitor spaces and equipment performance. Adding an HVAC control system that is a fairly packaged solution to a set of heating and cooling equipment in a building can greatly expand the capabilities of the facilities operators and allow for remote monitoring when staffing may be low, such as overnight shifts.

Have smart technologies (defined as a system with controls that self-monitor, analyze and report using technology) come up in discussion or been implemented on such projects? Has this integration impacted the project? If so, please give an example.

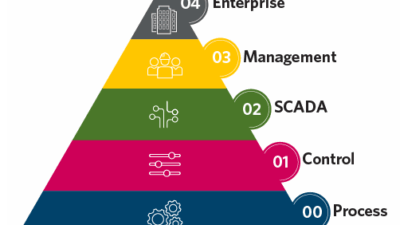

Jarron Gass: Yes, the topic of new or smart technology seems to come up in most industrial projects now. I believe this is because it helps drive innovation with an eye toward the future, as well as toward effectiveness, sustainability and efficiency. Taking advantage of technology will continue to help bring manufacturing back to the U.S. Technology has shifted workforce demands from unskilled to increasingly skilled labor, so enhanced worker and workplace safety continues to drive innovation through ongoing advancements. The availability of real-time analytics across manufacturing processes supports greater efficiency, reduced downtime and improved safety.

Jason R. Gerke: Smart controls, including systems that monitor, report and identify potential issues, are becoming more mainstream. These systems are either an add-on or a separate control system with the HVAC building automation system. While not popular yet due to cost and capability, the more data these systems receive, the more accurate their alerts and recommendations will be for operators.

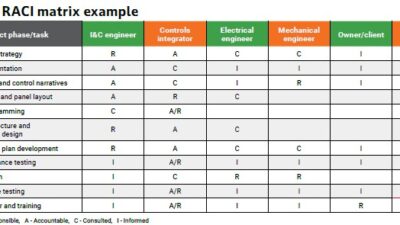

Cybersecurity and hacking are increasing concerns — are you seeing such concerns impacting your work on industrial and manufacturing facilities?

Jarron Gass: Fire alarm systems face the ongoing challenge of maintaining communication integrity across multiple components. Whether it’s wireless devices or the connection between the fire alarm control panel and the monitoring service, these systems are vulnerable. Safeguards must be in place to ensure that facility safety is never compromised.

What level of performance are you being asked to achieve, such as WELL Building Standards, U.S. Green Building Council LEED certification, net zero energy, Passive House or other guidelines? Describe a project and its goals, identifying the geographic location of the building.

Jarron Gass: Architects and engineers are increasingly expected to meet high-performance standards that promote sustainability, energy efficiency, and occupant health. Common benchmarks include LEED, which focuses on green building strategies; the WELL Building Standard, which emphasizes wellness through air, light and comfort; Net Zero Energy, where buildings produce as much energy as they use; and Passive House, which requires ultra-low energy consumption through airtight, insulated design. The Living Building Challenge is one of the most rigorous, demanding net positive energy, water and materials. These guidelines reflect a growing push for buildings that are not only efficient but also healthy and environmentally regenerative.

What types of sustainable features or concerns might you encounter for these buildings that you wouldn’t on other projects?

Jason R. Gerke: An important quality review task on highly sustainable projects is to review the HVAC system of operations. In addition to the HVAC sequences, other control systems in the building, whether connected or standalone, must be evaluated for the level of complexity. This complexity includes both operational and initial setup. It is easy to design and specify a perfect building with really sophisticated controls, but it is another situation to actually construct, commission and operate the building. The design team often wants to add several complexities to a project that are well-intended but may make the construction process and facility operations very complicated.

Matt Merli: Energy recovery for these facilities is a common design discussion for the architecture/engineering team. These buildings may have large outdoor air requirements and are physically quite large as well. This leads to an enormous amount of air, where energy recovery is not only a code requirement, but also has payback opportunities.

Describe energy storage systems at an industrial or manufacturing facility. What have you designed recently?

Jason R. Gerke: Ice storage continues to be a very useful solution when designing chilled water systems for an industrial building that requires chilled water for the process systems. Ice tanks can be used to reduce chiller runtime during peak hours and installed chiller capacity to meet instantaneous process loads. These types of buildings provide a great opportunity for synergies between comfort cooling and process systems to achieve a lower first cost, energy efficient operation and long-term flexibility in system capacity and plant expansion.