Within the latest versions of the energy codes and LEED rating system lie a framework for designing energy-efficient, decarbonized buildings. Understanding the emerging themes and key strategies included in them will help project teams.

Learning objectives

- Learn about the latest requirements and principles in the LEED rating system and ASHRAE Standard 90.1, including minimizing energy use, reducing reliance on fossil fuels and accelerating the use of refrigerants with low global warming potential

- Assess the benefits and challenges of replacing fossil fuel-based systems with electric alternatives, considering regional variations in electricity generation and the potential for reducing greenhouse gas emissions

- Explore the importance of commissioning, energy metering and monitoring-based commissioning (MBCx) to ensure that buildings perform as intended and maintain their energy efficiency over time.

Energy insights

- U.S. Green Building Council LEED v5 emphasizes decarbonization, quality of life and ecological restoration, with engineers having the most influence through energy-related strategies such as minimizing energy use, electrification and reducing refrigerant impact.

- Updated energy codes and standards like the 2022 edition of ASHRAE Standard 90.1: Energy Standard for Buildings Except Low-Rise Residential Buildings support this shift with stricter efficiency requirements, integration of renewables, grid-responsive design, performance monitoring and low-GWP refrigerants, enabling projects to close the gap between design intent and operational performance.

Version 5 of the U.S. Green Building Council (USGBC) LEED rating system (LEED v5) focuses on three impact areas: decarbonization, quality of life and ecological conservation and restoration. Credits that align with decarbonization are found in most of the LEED credit categories, but the highest concentration are found in the energy and atmosphere category. As consulting-specifying engineers, we have the most influence within this category, which rewards projects that do the following:

- Minimize energy use and reduce reliance on the on-site combustion of fossil fuels.

- Provide a positive contribution to electric grid decarbonization.

- Bridge the performance gap between design and operations.

- Accelerate the use of refrigerants with low global warming potential (GWP) and reduce refrigerant leakage.

Without delving too deeply into the details of individual LEED credits, this article will review a multipronged approach to decarbonizing building operations.

Minimize energy use and reduce reliance on the on-site combustion of fossil fuels

The phrase, “A building that just complies with the energy code is the least efficient building that you can legally build” encourages project teams to go beyond code compliance and seek deep energy savings in their building designs. It implies that it is easy to design a code-compliant building, but with recent updates to the energy codes — the International Energy Conservation Code and ASHRAE Standard 90.1: Energy Standard for Buildings Except Low-Rise Residential Buildings — this may not be as true as it once was.

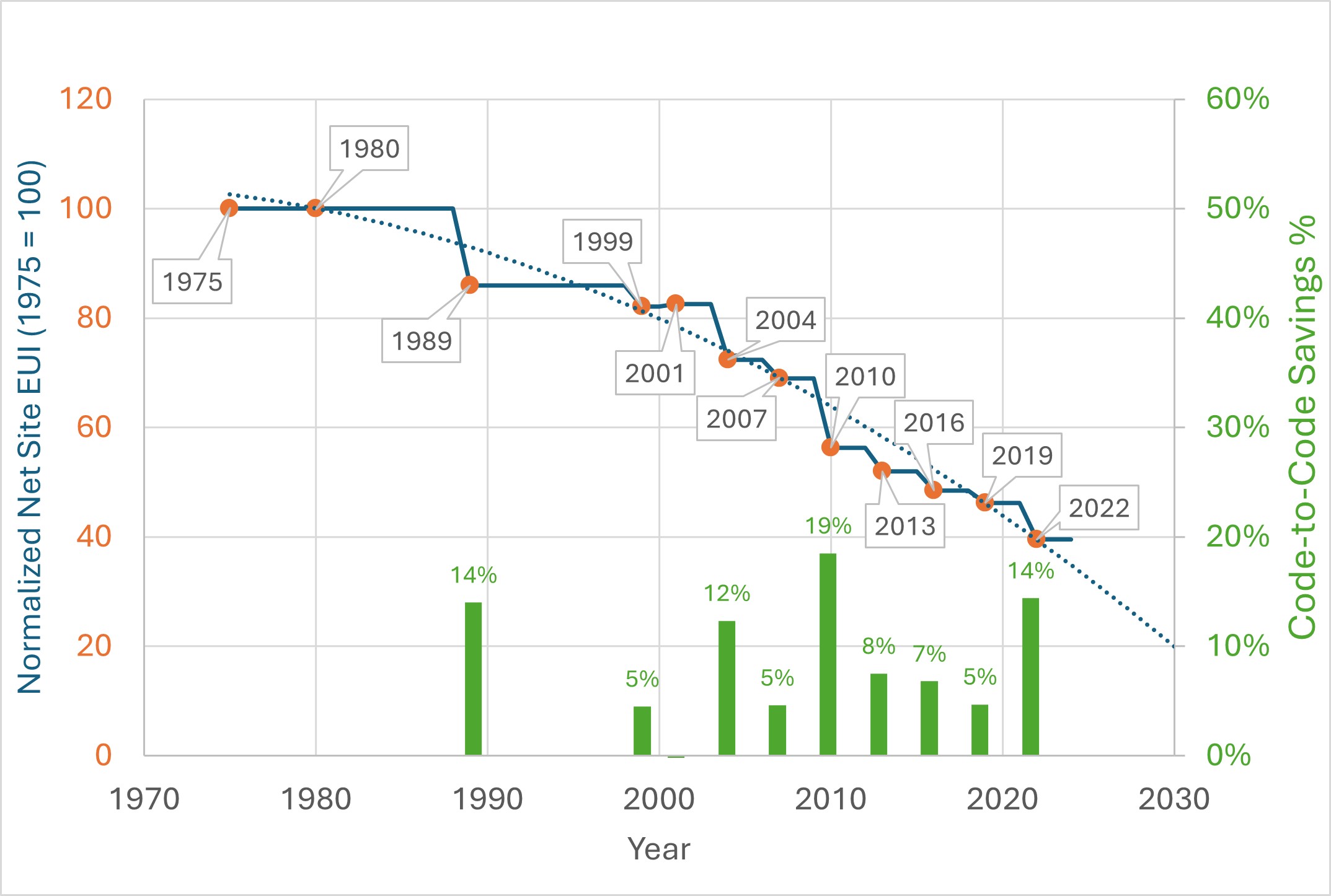

According to Figure 1, a building designed to comply with ASHRAE Standard 90.1-2022 uses 40% of the net site energy that the same building would have used had it been designed to comply with the original version of the standard in 1975.

ASHRAE, with the support of other industry partners such as American Institute of Architects, USGBC and the U.S. Department of Energy, have an ambitious target to revise Standard 90.1 over the next three code cycles such that a new building designed to comply with ASHRAE Standard 90.1-2031 will be ultra-low energy and potentially net zero energy (i.e., the building produces more energy than it consumes annually).

This relentless push toward zero has introduced new requirements into the 2022 version of the ASHRAE 90.1 including, but not limited to:

- Envelope backstop: Previously, projects using an energy model to show code compliance had unlimited trade-offs between the building envelope and heating, ventilation and air conditioning (HVAC), lighting and service-water heating systems with much shorter equipment life. This created a loophole that allowed buildings with envelope performance much worse than the prescribed minimum to still comply. This requirement limits trade-offs between envelope components that aren’t designed to meet minimum code requirements and HVAC, lighting and service-water heating systems that are designed better than minimum code requirements. It emphasizes the importance of a well-insulated building envelope as it can be difficult to impossible to perform comprehensive retrofits to existing building envelopes. This requirement applies to performance-based compliance paths that use a whole-building energy model, but will now require projects to use additional software, such as COMCheck, that calculates envelope performance factors in accordance with the ASHRAE 90.1 building envelope performance compliance option.

- Thermal bridging: For many years, the energy codes have addressed common thermal bridges in the building envelope, such as steel-framed walls. However, there are many other instances of linear and point thermal bridges that can compromise the envelope. Except for warmer climate zones, ASHRAE 90.1-2022 now requires accounting and mitigation of several of these thermal bridges such as those that occur at the following portions of the building envelope:

- Roof to wall intersections

- Intermediate floor intersections

- Exterior cladding supports

- Opaque wall and vertical fenestration intersections

- Other elements and building assembly intersections

- Renewable energy: For the first time, the 2022 version requires installation of equipment for on-site renewable energy. Unless one of the listed exceptions apply, the renewable energy system must have a rated capacity of 0.50 watts/square foot multiplied by the sum of the gross conditioned floor area for all floors up to the three largest floors.

- Energy credits: ASHRAE 90.1-2022 has a prescriptive requirement to earn a minimum number of energy credits. With the assistance of Pacific Northwest National Laboratory, ASHRAE has developed a collection of 33 energy efficiency, renewable energy and load management measures for project teams to choose from. Energy credits provide additional required prescriptive savings that are more flexible than base prescriptive requirements, having a goal of demonstrating 5% total building energy cost savings in each climate zone.

As energy codes have gotten more stringent, it has become more difficult for design teams to meet all applicable prescriptive requirements for a given project. Fortunately, whole-building energy models may be used when projects can’t meet (or choose not to meet) all the prescriptive requirements. Energy models are one of the best tools that design teams have to design high-performance, cost-effective buildings.

In addition to being used for code compliance, energy models can also be used for several other design aspects like electrification, reducing thermal loads and electric and/or thermal storage. ASHRAE Standard 209-2024: Building Performance Simulation Process establishes minimum requirements for the process of using simulation to evaluate building performance and inform decision making. Even when compliance with Standard 209 is not required for a project, there is value in reviewing and following its principles, as it outlines many effective use cases for energy models, especially early and often in the design process.

Electrification

While decarbonizing through energy efficiency is something that has been encouraged since the inception of the energy codes, it doesn’t specifically address the amount of fossil fuel combustion (known as Scope 1 emissions) from space heating, service water heating and miscellaneous loads such as cooking, laundry and other process equipment. The concept of reducing or eliminating the greenhouse gas (GHG) emissions from on-site combustion of fossil fuels by replacing gas-fired furnaces, boilers and water heaters with equipment that uses electricity is referred to as electrification.

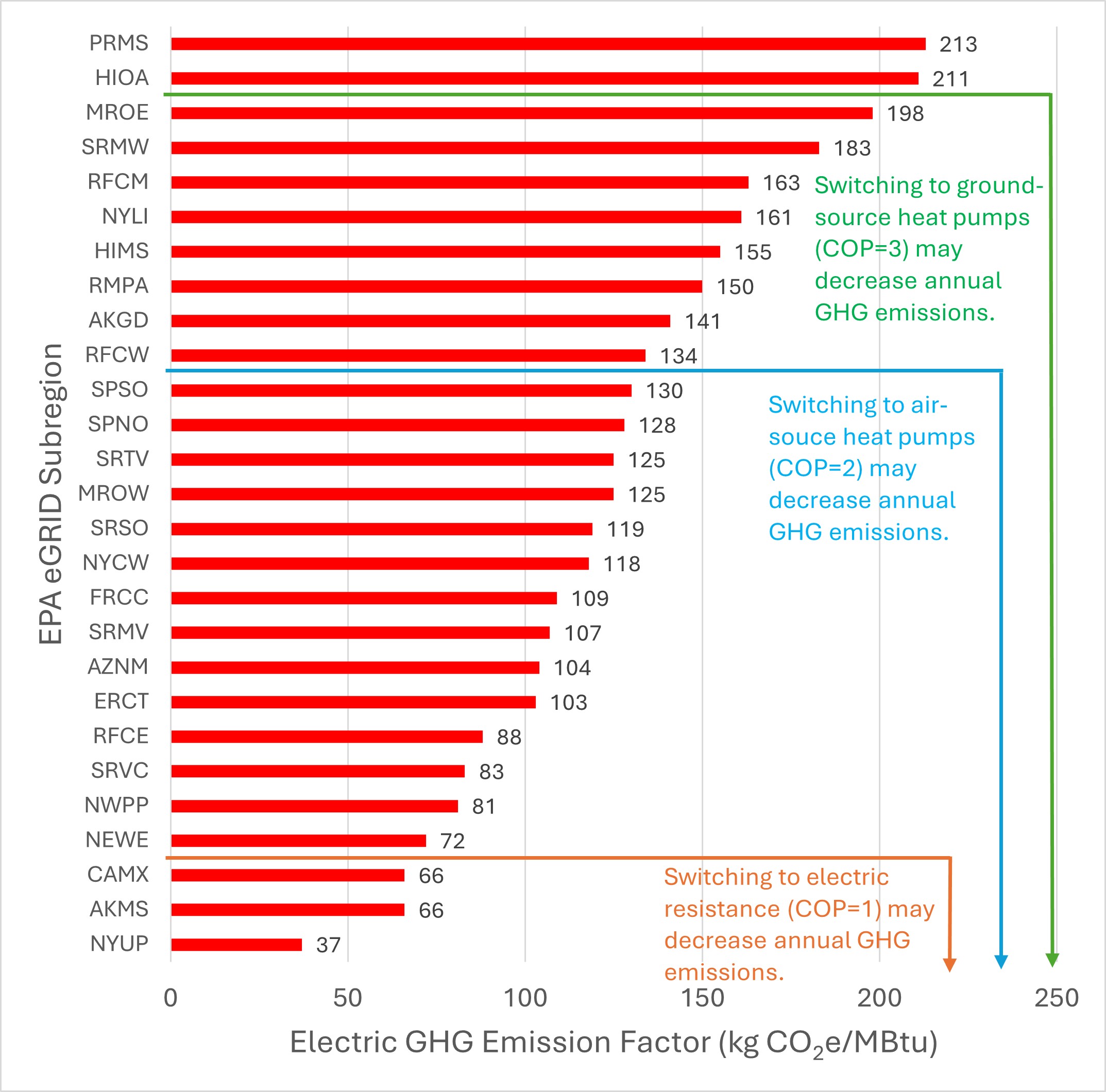

However, before specifying electric reheat coils or electric hot water boilers on all future projects, consider that not all electricity is created equal. For instance, electricity is produced by many diverse sources of energy, including, but not limited to: wind, solar, nuclear and fossil fuels. This combination of energy sources results in electricity from different regions have varying GHG emission factors (given in terms of kilograms of carbon dioxide per million British thermal units, or kgCO2e/MBtu).

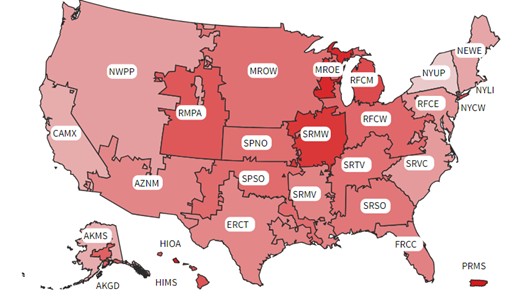

Figures 2 and 3 show the average annual emission rates of electricity generated in various U.S. Environmental Protection Agency Emissions & Generation Resource Integrated Database (eGRID) regions, ranging from 37 to 213 kgCO2e/MBtu. In contrast, the GHG emission factor of natural gas is 53 kgCO2e/MBtu and assuming a boiler or water heating operating at 80% efficiency, that gas-fired piece of equipment would emit 66 kg of CO2e per MBtu of heating load.

As of 2022, Figure 3 shows that there were only three EPA eGRID regions with electricity clean enough to make switching from an 80% efficient gas-fired furnace or boiler to an electric resistance heater or boiler result in a net decrease in GHG emissions: AKMS (Alaska), CAMX (California) and NYUP (Upstate New York).

Fortunately, there are technologies such as air-source heat pumps and air-to-water heat pumps that have minimum efficiencies around 2.0 coefficient of performance (COP) down to an outside air temperature of 17°F (as required by ASHRAE Standard 90.1). Assuming an annual average COP of 2.0, electrifying with these technologies will produce a net decrease in 2022 GHG emissions in about half of the remaining EPA eGRID regions (see Figure 3).

Finally, ground-source heat pumps typically have minimum efficiencies greater than 3.0 COP down to an entering water temperature of 32°F (as required by ASHRAE Standard 90.1). Therefore, with an assumed annual average COP of 3.0, Figure 3 shows that ground-source heat pumps will produce a net decrease in 2022 GHG emission in all by two EPA eGRID regions: HIOA (Hawaii) and PRMS (Puerto Rico). Does that mean that there are regions of the U.S. where electrification isn’t beneficial? It may appear so, but only in the short term (see sidebar, “Models show electrification options in a manufacturing facility”).

Finally, full electrification may not be feasible or cost-effective for all owners or project teams, particularly when retrofitting existing buildings. When it comes to electrifying a hydronic heating system, heat pump technologies are more expensive than electric resistance or gas-fired heating equipment, so a hybrid approach (i.e., air-to-water heat pumps plus gas boilers, or air-to-water heat pumps plus electric boilers) may provide a reasonable compromise for cost and GHG emissions.

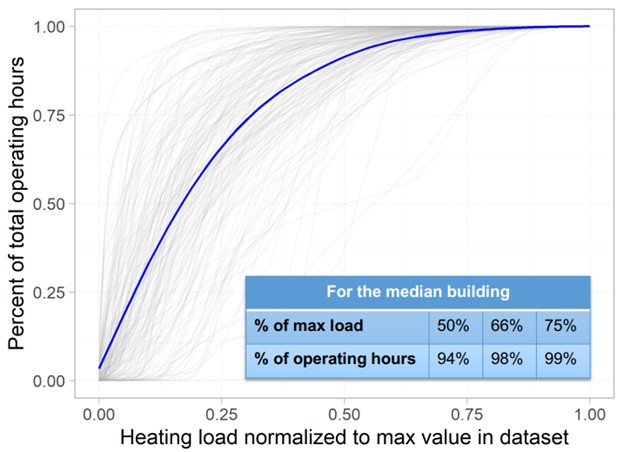

For example, Figure 4 is from a study of over 150 buildings, showing the hot water plant load distribution in terms of the cumulative fraction of operating hours for each plant, normalized to each plant’s maximum load, with the blue line representing the median distribution. The median building spends 94% of the time operating at loads at or below 50% of the maximum and 30% of the time at loads below 10% of the maximum. Therefore, by analyzing a building’s heating load profile, engineers can right-size a partially electrified heating system, such as installing a series of modular air-to-water heat pumps to handle 50% of the total load and at least two condensing gas-fired hot water boilers sized for 50% of the total load to handle the minority of annual operating hours where the hot water system is near its peak.

Provide a positive contribution to electric grid decarbonization

A frequent concern about electrification is the electric grid’s ability to keep up with the increase in demand. While this is something that electric utilities and power plants must plan for, building designers have an opportunity to lessen the impact that this increased electric demand will have on the grid. Here are three core concepts.

Reduce peak thermal loads: ASHRAE Standard 209-2024 includes a process for using simulation to evaluate building performance and inform decision making. While the standard provides several modeling cycles that can demonstrate compliance, at least one of them must be Modeling Cycle #3 — Load Reduction Analysis. This cycle evaluates strategies that will reduce not only annual energy use but also peak coincident heating and cooling loads. Many case studies have shown that implementing strategies that reduce the size of HVAC systems are often the most cost-effective, particularly if the cost savings of down-sizing or eliminating those systems is accounted for. In fact, some high-efficiency HVAC systems such as chilled beams are not feasible unless reducing the loads from interior gains and the building envelope are prioritized.

Thermal load reduction strategies include the following:

- Design a highly insulated building envelope components that performs better than ASHRAE Standard 90.1-2022.

- Design a balanced ventilation system where the outside and exhaust airflows are within 10% of each other.

- Design and construct a building envelope that minimizes infiltration as verified by an air leakage test.

- Provide exhaust air energy recovery to precondition ventilation air.

- Comply with ASHRAE 90.1-2022 requirements for thermal bridges.

- Apply high-efficiency interior lighting.

Renewable energy: While ASHRAE 90.1-2022 requires a minimum amount of renewable energy, going beyond this threshold can reduce the demand on the electric grid. Additionally, a prerequisite net zero energy status is for the building to produce as much energy as it consumes annually.

While it’s preferrable for the renewable energy system to be located on the project site or the campus on which the project is located, contracting with a new, off-site renewable energy system is the second-best option. Otherwise, engaging in a long-term contract to purchase green power or renewable energy certificates is usually acceptable. At the very least, designing a building to be solar-ready can facilitate the addition of on-site renewable energy in the future. Such solar-ready provisions include designating a dedicated and appropriately sized solar zone, considering panel-mounting options, reserve space, capacity and pathways for the electrical interconnection infrastructure.

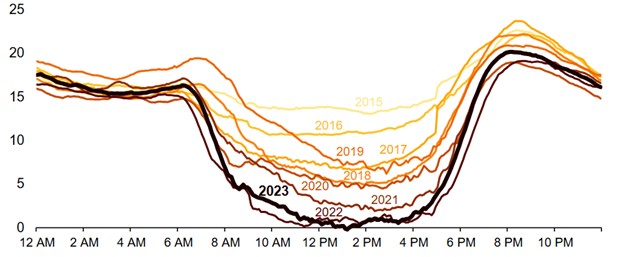

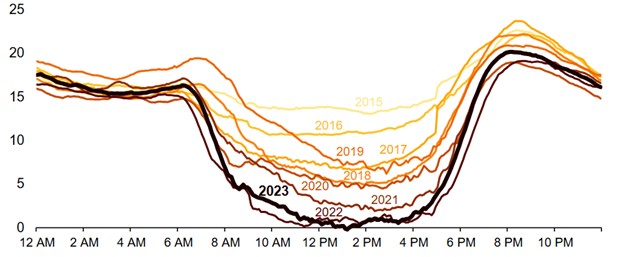

Grid-interactive measures: While electrification and renewable energy are important steps to decarbonization, they can create unintended consequences within the electric grid. For example, as more solar capacity has come online in California, grid operators at the California Independent System Operator have observed a drop in the net load in the middle of the day when solar generation tends to be highest.

However, there is an increased need for electricity generators to quickly ramp up energy production when the sun sets and contribution from solar photovoltaic panels falls. As illustrated in Figure 5, this pattern is often called a “duck curve,” and it creates a challenge for grid operators to balance supply and demand with conventional power plants (e.g., nuclear, coal-fired and natural gas-fired plants).

By employing the grid-interactive measures below, buildings can help to flatten or avoid the duck curve in their region:

- Provide on-site electric storage and/or thermal storage as well as automatic load management controls programmed to store energy during off-peak/low grid carbon intensity periods and use the stored energy during on-peak/high grid carbon intensity periods.

- Enroll in a demand-response program and use system- or building-level controls that automatically reduce electricity demand for the HVAC, lighting, receptacles, service water heating and/or electric vehicle supply equipment systems in response to triggers that represent periods of high electric grid demand or high grid carbon intensity.

Bridge the performance gap between design and operations

Many building owners express disappointment when their buildings are not constructed or do not perform the way they expected. As energy codes get more stringent and building controls get more complex, these performance gaps have gotten bigger. In response, the energy codes and LEED rating system have added more quality assurance processes and feedback mechanisms in the form of commissioning and energy metering.

Energy metering: As the saying goes, “You can’t manage what you don’t measure.” This is why ASHRAE 90.1 first added requirements for whole-building energy monitoring and electrical sub-meter monitoring in 2013. By providing enough metering, recording and reporting capabilities to a building, its operators can more effectively manage energy performance. In addition to requiring whole-building energy monitoring of electricity, fossil fuels and district thermal energy, the 2022 version of ASHRAE 90.1 requires electrical sub-metering of HVAC, interior lighting, exterior lighting, receptacle circuits and commercial refrigeration systems. Going beyond what is required by ASHRAE 90.1, it may also be advantageous to meter elevators, commercial kitchen equipment, large process equipment and on-site renewable energy systems.

All this metered data may be difficult for an operator to understand, so having a remotely accessible energy information system can help them visualize and analyze the data, especially if it can automatically identify energy use anomalies, assist with building energy benchmarking and report GHG emissions.

Commissioning: For many code cycles, ASHRAE 90.1 has required some level of commissioning, functional testing and verification — first for HVAC systems controls, then for lighting controls and then for the building’s continuous air barrier. Starting in ASHRAE 90.1-2019 and continuing with 90.1-2022, commissioning, verification and testing requirements also extend to the following:

- Dynamic glazing

- Service water heating systems and controls

- Automatic receptacle controls

- Energy monitoring

- High-end lighting trim and lumen maintenance controls

- Service water pressure-booster system controls

- Elevator standby mode controls

- Air curtains

- Pumps

Using the commissioning process prescribed by LEED increases the chance that the owner gets a building designed to meet their requirements as well as constructed and started up in accordance with the design documents.

However, if commissioning stops there, the building is more likely to experience performance degradation as equipment fails or as control setpoints and sequences are changed or overridden. That’s why the LEED rating system encourages monitoring-based commissioning (MBCx) for at least the first three years of operation, in the hope that building owners will continue the practice indefinitely to keep the building meeting or exceeding its design intent.

MBCx is a process that typically uses fault detection and diagnostics (FDD) software to continuously monitor building system trends, automatically identifying instances of energy waste, occupant discomfort and faulty equipment operations. As a best practice, FDD software should be able to prioritize recommendations for repair of identified faults and be capable of transmitting the prioritized fault repair recommendations to remotely located authorized personnel.

Accelerate the use of refrigerants with low GWP and reduce refrigerant leakage

Refrigerants found in HVAC, refrigeration and heat pump water heating equipment are another source of GHG emissions, specifically when they leak during normal operations or when refrigerant is lost at the end of the equipment’s life. It’s difficult for most buildings to avoid using refrigerant-based HVAC equipment, so the best we as engineers can usually do is specify equipment that use refrigerants having low GWP.

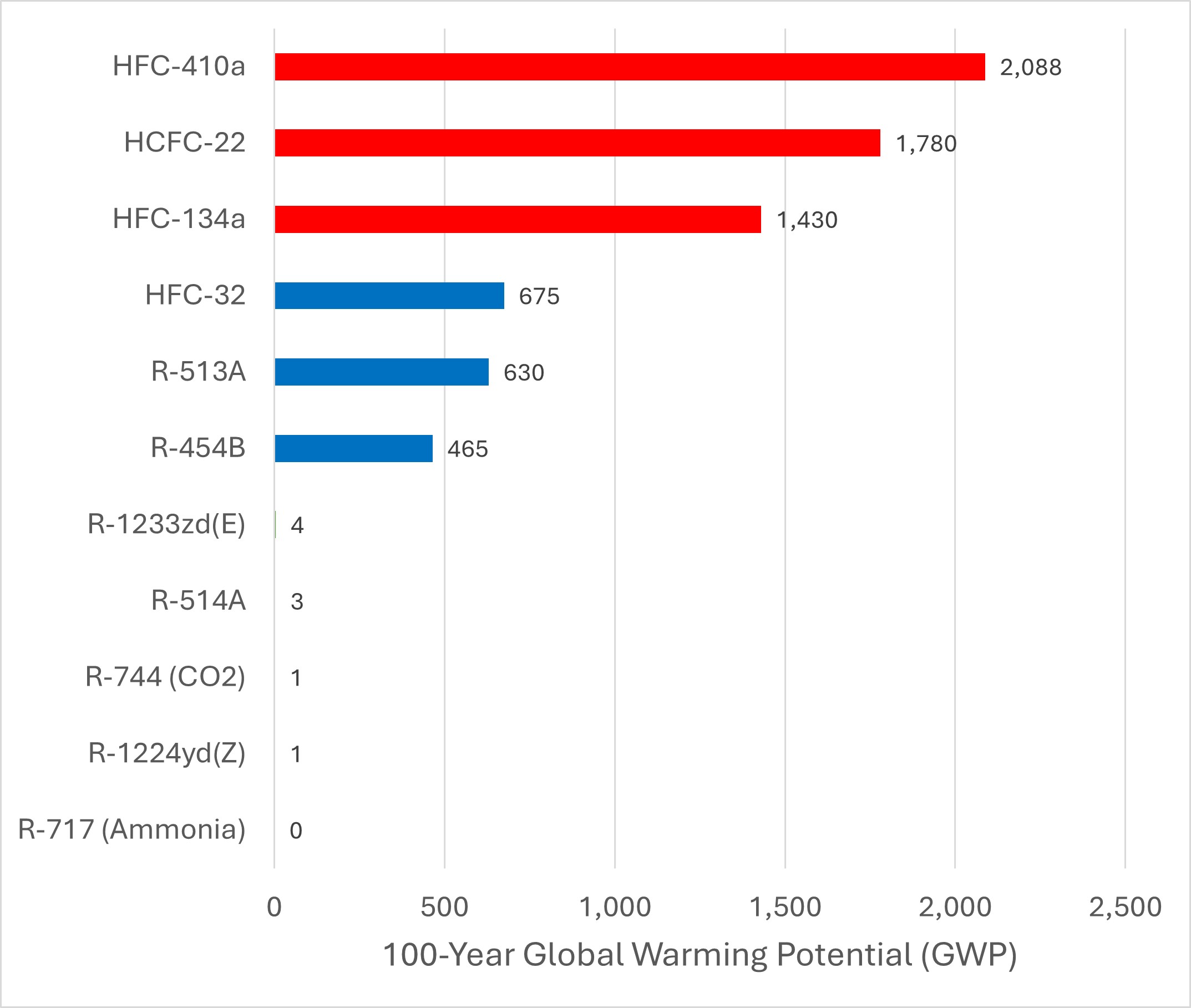

The American Innovation and Manufacturing Act of 2020 (AIM Act) allowed the U.S. EPA to phase out hydrofluorocarbon (HFC) and HFC-blend refrigerants having a GWP of less than 700. This went into effect for new chillers, air conditioners and heat pumps installed after Jan. 1, 2025, and will go into effect for new variable refrigerant flow systems installed after Jan. 1, 2026. Figure 6 provides a comparison of common refrigerants.

The LEED rating system rewards projects that use refrigerant-containing equipment having GWPs sufficiently lower than specified benchmarks. Additionally, refrigerant leakage can be reduced by using self-contained equipment with no field-installed piping and by using automatic leak detection systems. Where field-installed refrigerant piping is installed, using brazed or press-type fittings may also reduce leakage.

The latest versions of LEED and ASHRAE Standard 90.1 have provided the structure and foundation for designing energy efficient, decarbonized buildings. It’s now up to design teams to apply these requirements and principles into their standard design practices.