To ensure integration and avoid missed coordination, proactive communication was required on an instrumentation and controls project for a semiconductor fab.

In many cases, integration issues on a project can be traced back to gaps or oversights during the design phase. One notable example involved a semiconductor fabrication plant with multiple support buildings. The instrumentation and controls (I&C) designer on the project had joined the team just six months out of school, stepping in as the project entered construction. Although initially focused on responding to submittals and requests for information, it quickly became clear that the project faced more significant design-related challenges.

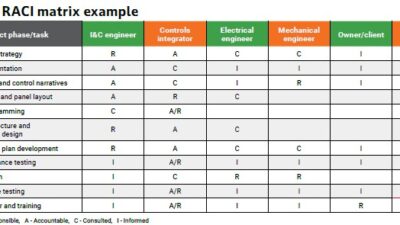

A critical part of successful I&C design involves close coordination with mechanical and process-chemical teams, especially when developing mechanical and instrumentation diagrams and process and instrumentation diagrams (P&ID). On this project, however, there had been little to no coordination between the I&C and mechanical teams. This disconnect led to conflicting design assumptions.

The client had clearly requested that all heating, ventilation and air conditioning (HVAC) equipment and field instruments be hardwired to the facility monitoring and control system (FMCS), with each signal routed individually to a control panel and then connected to the supervisory network. This method of individual hardwired signals allows for redundancy so that if a cable is damaged, the FMCS can still monitor the other signals coming from the equipment.

On the other hand, if a singular network cable is used and goes down, then the entire connection to the piece of equipment is lost. The I&C team designed accordingly, delivering a comprehensive FMCS layout. Meanwhile, the mechanical team independently developed a building automation system (BAS) network based on the more common approach of using a single network cable from each piece of equipment to a central panel. While standard for most projects, the BAS design didn’t meet the client’s redundancy requirements and omitted critical hardwired monitoring points.

This misalignment went unnoticed during design reviews. As construction began, the general contractor followed the mechanical drawings, implementing the BAS setup. As a result, several control points critical to the I&C system were never installed.

To resolve the issue, the team proposed a hybrid BAS-FMCS approach, which the client approved. While the fix wasn’t overly complex, it led to delays, change orders and extensive rework, including revised wiring, control logic updates and added coordination between trades.

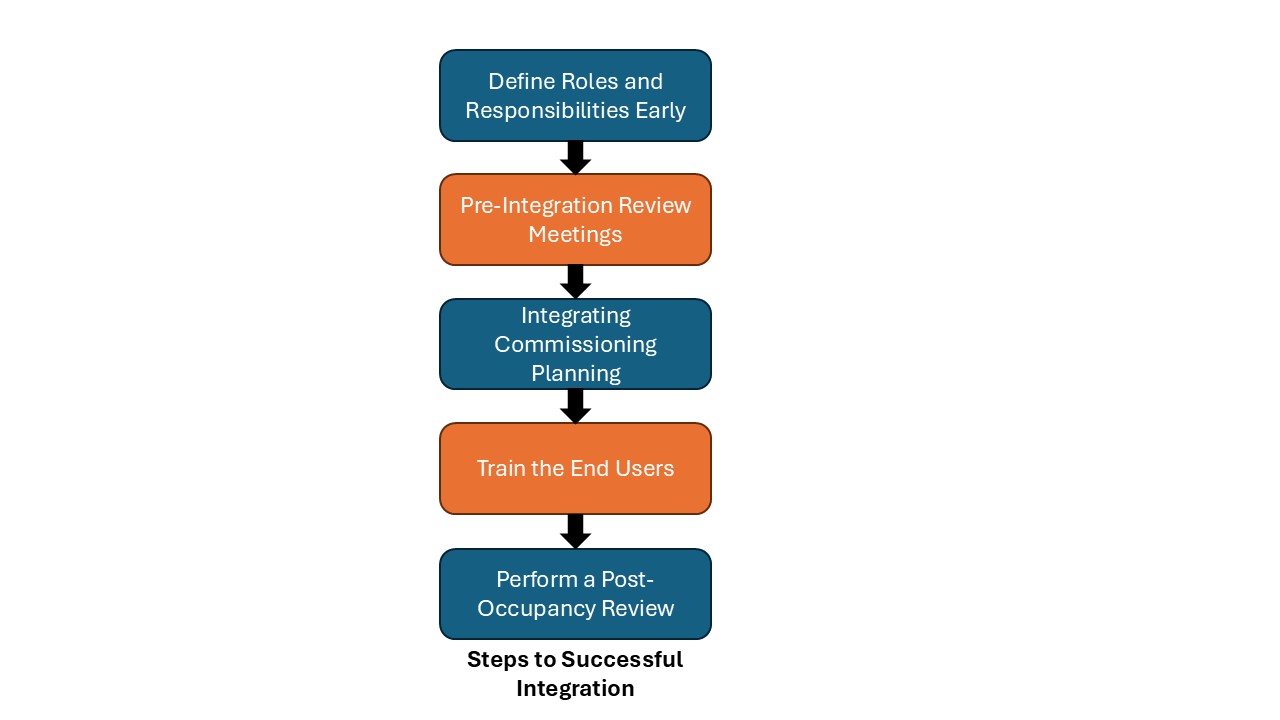

This experience highlighted how essential early and consistent cross-disciplinary coordination is to achieve successful integration. Even small disconnects can escalate into costly problems. The project reinforced the value of proactive communication, asking clarifying questions and ensuring all designs align, not only within a specific scope but across the entire project team.

Ultimately, good integration is a direct outcome of good design and making sure all components work together from the start is what leads to efficient execution and client satisfaction.