Marc McManus, St. Louis office engineering leader, Alex Oliver, senior mechanical engineer, and Colin Hale, mechanical engineer/energy services, were recently featured on the podcast Engineering Tomorrow to discuss the state-of-the-art Johns Hopkins Applied Physics Laboratory.

The team began the interview reminiscing about how they each became interested in engineering and how they eventually decided on mechanical engineering for their careers. They also discussed what makes a good engineer in this particular field. McManus noted that, besides the engineering skills needed, they look for good problem solving, teamwork and communication abilities.

They then went into the details of the 260,000 gsf Johns Hopkins University Applied Physics Laboratory (APL) Building 201 and the highly complex engineering and architectural opportunities the project provided. The client, as the team discussed, is the Research and Exploratory Development Department (REDD) – a highly advanced group of the nation’s top scientists, engineers and technical specialists that conduct programs to ensure national security and advance the frontiers of science and engineering.

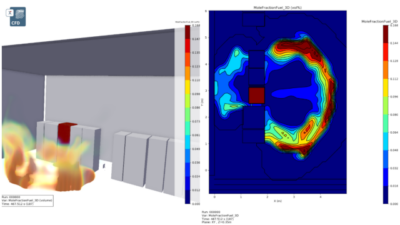

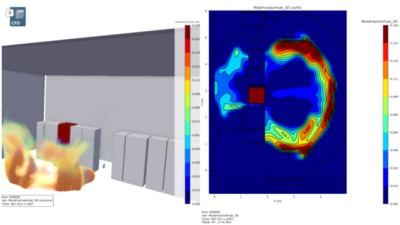

The team explained the many space types inside the building including THZ and quantum mechanics optics labs, MBE and MTS Labs, dry labs, an imaging suite, NMR’s, and a metal shop. Also included are open labs for biological and health sciences programs with flanking support labs for microbiology, molecular biology, biochemistry, analytical instrumentation, and sequencing labs, as well as virology, tissue culture, environmental chambers, mass specs, and radioisotopes. In addition to the laboratory spaces, the building boasts a four-story atrium that brings a massive amount of natural daylight into the space.

Sustainable energy features are also vast. As Hale explained, the building boasts a 180,000 CFM energy recovery runaround loop and nine air handling units all with energy recovery capabilities. They also used an energy model to optimize building performance. All of these factors contribute to a current target of a LEED Silver rating.

The team discussed many other topics during the interview including collaborating with different disciplines, teaming structures of projects, designing for proprietary spaces, the timing of construction schedules and much more.

A few excerpts from the interview:

“There are easy jobs and there are challenging projects. The technically challenging projects are the fun ones. Sometimes you know you have a big hill to climb, but you work really hard, you leverage the collective strength of the firm, and then you come up with the best solution to present to the client and they are happy with it — that is what I get up in the morning to do.” –Marc McManus

“Those types of spaces — particularly on this project — where we had a wide variety of unique equipment and systems that we haven’t integrated in the same manner ever before, those are the most fun projects to work on.” –Alex Oliver

“The fun part of these challenging projects is the iterative approach you have to take. It’s working through the solution multiple times and the first time, maybe you’re not right and have to work through it with your team and the owner a few times. That’s the fun part – figuring out the best solution through the course of those iterations.” –Colin Hale

Project Highlights:

- 260,000 gross square feet

- IECC 2015, LEED Silver (Pending)

- 167,000 CFM total 100% OA lab supply; lab AHU’s have fan arrays for partial redundancy

- 200,000 CFM total building supply air; every AHU with energy recovery

- 180,000 CFM total (150,000 CFM + 30,000 CFM) N+1 high plume laboratory exhaust fan array

- 225,000 CFM engineered smoke control system for the atrium.

- 18,000 MBH high efficiency condensing HHW plant with N+1 boiler not included in total

- 1,280 ton CHW plant with N+1 chiller not included in total

- Laboratory equipment process cooling system.

This article originally appeared on CannonDesign’s website. CannonDesign is a CFE Media content partner.