Although he currently resides in Manhattan, former President Bill Clinton hasn’t forgotten his Arkansas roots. When it came time to be part of a larger effort to revitalize Little Rock’s downtown and riverfront, the city became an easy choice for the location of the library and museum that would preserve and reflect the eight-year history of Clinton’s service as 42nd president of the United States.

Nestled along the south bank of the Arkansas River inside a new 27-acre city park, the William Jefferson Clinton Presidential Center opened its doors this past fall and houses not only a replica of the Oval Office, but more than 77 million documents, 75,000 artifacts, 1.8 million photographs and 40 million e-mail messages.

All presidential libraries have to meet environmental, operational and redundancy standards of the U.S. National Archives and Records Administration (NARA). These guidelines are specific and demanding with respect to the control of temperature, humidity and gaseous contaminants within the various spaces in a facility of this type. However, in keeping with his championing of many green goals while serving as president, Clinton also desired that the library be built to LEED standards. At first, this seemed problematic, as high-tech, interactive facilities of this sort generate significant lighting and equipment power loads, as well as large cooling loads, to accommodate the large number of visitors.

Furthermore, the space needed to be easily modifiable to accommodate new exhibits, and from an aesthetic perspective, it needed to provide visual interaction with downtown Little Rock. And of course, the architecture needed to seamlessly incorporate M/E/P systems. To create the visual connection with the city, Polshek Partnership, the architect on the library, proposed that the library’s western exposure be constructed entirely of low-iron clear glass. While certainly a beautiful architectural expression, the glass wall would create an extremely large cooling load—contrary to the project’s LEED goals. Flack + Kurtz’s team, in conjunction with Polshek Partnership, analyzed many wall configurations to find one that would maintain the desired architectural effect but decrease the associated cooling load.

The glazing system ultimately consisted of a primary glass wall, which defines the building envelope, and a secondary exterior glass wall across an adjacent exterior walkway, which in essence, creates a variation of the double-envelope systems more commonly employed in Europe.

The glass that defines the building envelope is an insulated assembly of low-iron clear glass. The secondary surface also includes a high-performance coating to reduce the sun’s energy by 55%. Further cooling improvements were realized by applying an opaque frit to various portions of the outermost surface of the primary glass to even better block solar heat.

The elevated exterior walkway is also part of the solution. It contains a piece of clear laminated glass on the outboard side of the path, and this additional assembly absorbs portions of the sun’s energy in the invisible wavelengths while still maintaining the desired visual connection to downtown Littlerock.

The heat absorbed by the glass is vented through louvered elements in the top of the walkway. The complete system decreases heat gain by 65% and successfully maintains a clear visual impression of the building.

So much for the facility’s exterior; let’s take a look inside. As noted, today’s interactive libraries and museums can consume a great deal of power. In plotting the facility’s initial lighting and display-equipment loads, the numbers were very high and more consistent with facilities not seeking LEED accreditation.

Keeping power and heat in check

As a result, the M/E team worked closely with the museum’s design firm, Applebaum Assocs., to establish power loads at 30 watts per sq. ft. This wattage is significantly less than comparable high-tech museum spaces, but still met programmatic goals for the spaces. That being said, the team was even able to cut those numbers in half through considerable evaluation of lighting and display options.

And in line with green goals, a portion of the library’s power (5%) is also generated through the use of roof-mounted photovoltaic cells. The 60-kW supplemental power is introduced into the overall building electrical distribution. But the system goes beyond reducing utility electric consumption; it also provides shade for the roof, further reducing the cooling load.

Simply radiant

Despite all the anti-heat measures, cooling loads were still significant, and the M/E team had to dig deep for creative solutions. A traditional air-conditioning system was ruled out. Cooling supplied with overhead ducts and air diffusers would have required extremely large airflows, meaning large ducts, multiple air diffusers and large-capacity air-handling systems. This equipment also would have required large equipment rooms and a large ceiling cavity to contain the ducts—antithetical to the building’s slim architectural profile. And from an interior design perspective, the ceiling would have needed to house more diffusers than the architectural design could accommodate. Finally, energy costs associated with an all-air system would have been significant and in conflict with LEED goals.

Instead, the M/E team proposed a radiant-floor system. Not only did this solve equipment housing issues, it proved extremely effective in removing both the absorbed heat of the sun and the heat generated by high-power display lighting.

Traditionally, conventional cooling systems allow energy from external sources to heat the floor, which is then re-radiated, convected to the space, and finally, removed by blowing cold air into the room. By contrast, radiant floors more efficiently transfer this heat. Energy impingement on the floor is directly absorbed into the radiant cooling-water loop, and the heat never enters the occupied space. Consequently, the energy efficiency of a radiant cooling system is a great improvement over an air system. Water has a greater heat capacity than air, and less water mass is required to be circulated than in an air system. In fact, in an air system, both air and water are circulated. Furthermore, the radiant floor can double as a heat source in colder months.

At the same time, due to the NARA ventilation and humidity control requirements, the M/E team could not completely do away with air delivery. Still, with equipment housing and energy consumption concerns at the forefront, the team tried to use displacement ventilation wherever possible. Displacement air systems, which deliver low-velocity air at the floor level, allow temperatures to stratify and essentially provide cooling to the occupied zone. Additionally, the air in the occupied zone is cleaner as it is provided only to the occupied zone, opposed to overhead air systems, where dirty return air can be mixed with clean supply air.

The final component of the radiant system was condensing-type boilers. This equipment selection allowed a further reduction of energy because radiant-heated floors operate at lower temperatures—80°F to 85°F—as compared to traditional heating systems, which operate at 180°F. Condensing boilers also burn natural gas at efficiencies greater than 90% without discharging pollutants associated with other fuels. Traditional non-condensing boilers operate in the 80% efficiency range.

Presidential leadership

Energy consumption in this project was reduced by 35% below that of a typical code-compliant building. The most significant reduction is attributed to the use of radiant floors, condensing boilers and displacement cooling, and was achieved by integrating the features into the building in a logical way. Ultimately, the energy-responsible design was incorporated into the core goals of the project. Additionally, because the project proceeded based on an integrated approach, it was more successful with respect to capital cost, operating cost and overall design.

At the end of the day, the William Jefferson Clinton Presidential Center serves as an example that the visions and requirements of energy-responsible design can indeed be met. And its leadership in terms of design also carries over to leadership in community development. This year, with an anticipated 300,000 visitors, the library has inspired $800 million in downtown development in Little Rock.

Finally, the subject of leadership can’t be noted without invoking the memory of Norman Kurtz, who recently passed away. Mr. Kurtz founded Flack + Kurtz with principles that included energy-efficient and responsible design long before the advent of LEED and similar organizations. Prior to his recent passing, Mr. Kurtz maintained an integral role in the design of this project due to the similarity between its goals and his personal principles.

Early Detection a Presidential Priority

Visitors to the new Clinton Presidential Library and Museum will see a number of interesting things, but one thing they will not see is the library’s advanced smoke-detection system.

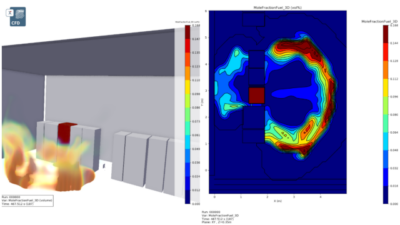

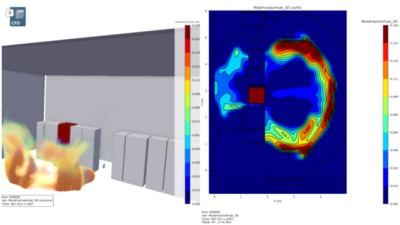

Beyond its vault-like walls that can withstand fire for four hours, fire-protection engineer Scott Lacey of Cromwell Architects Engineers, Little Rock, wanted measures that would prevent fires at a much earlier stage. For the library’s three records rooms, he specified a highly sensitive air-sampling system with two independent smoke-detection systems covering the rooms. The systems, which are divided into eight zones, employ high-efficiency aspirators that draw air from 68 sampling points.

According to Vesda, the detection system’s manufacturer, the Laserscanner unit contains a dual-stage filter. The first stage removes dust and dirt; the second provides a barrier of clean air that keeps the optical surfaces uncontaminated. When the air sample passes through the detection chamber, it is exposed to a laser-light source. If combustion particles are present, light is scattered within the chamber and a scanning valve mechanism identifies which sampling pipe is carrying the smoke.

Lacey has used the technology on previous jobs, including a data center in which the system actually engaged. “A capacitor on a generator was going bad and the system alerted the staff, and they were able to find it before fire broke out or any of the fire-suppression systems activated, even though it was on the other side of the building,” he says.