Fiorentino Plaza Housing Development, New York, NY

Engineering firm: H2M architects + engineers

2019 MEP Giants rank: 82

Project: Fiorentino Plaza Housing Development

Location: New York, NY, U.S.

Building type: Housing development

Project type: System overhaul

Engineering services: Electrical, power; HVAC, mechanical; architectural

Project timeline: March 2018 to December 2018

MEP/FP budget: $802,000

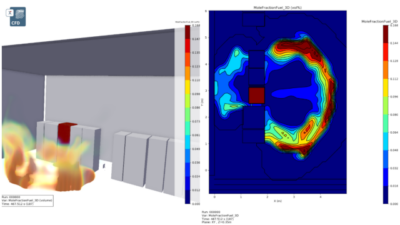

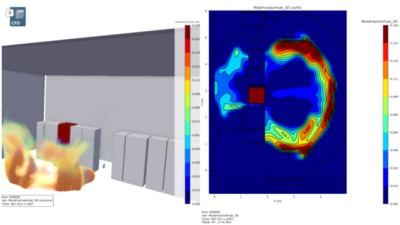

Challenges

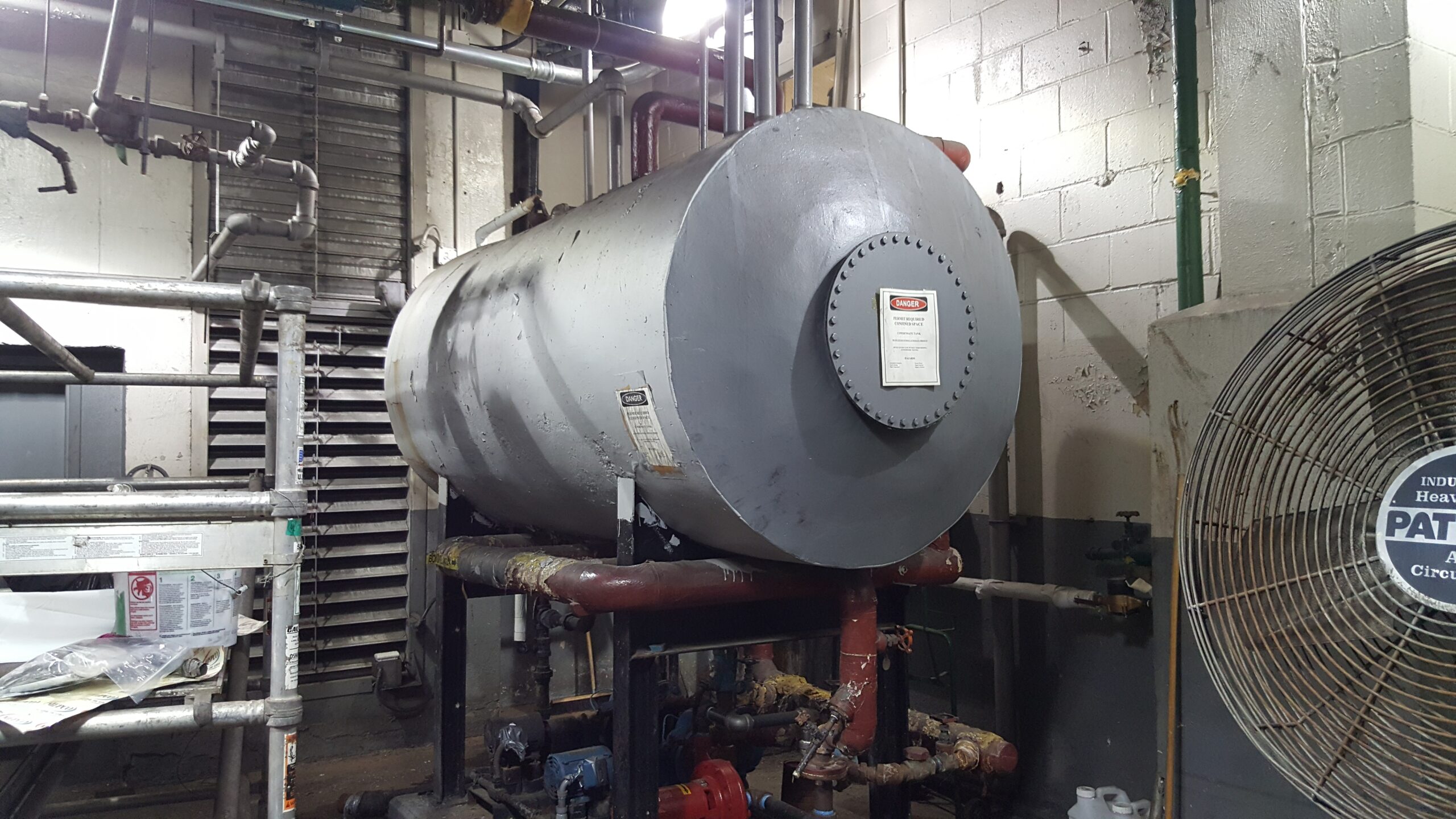

The Fiorentino Plaza Development consists of eight four-story buildings. The central boiler plant’s two 200 HP low pressure steam fire tube boilers and all associated ancillary steam equipment (condensate return unit, boiler feed unit, blow down separator, chemical feed unit, etc.) were to be replaced. The design included abandonment of the existing 12,000 gallon buried fuel oil tank in accordance with NYC Fire Code. A temporary rental boiler was also included in the design to ensure heating and domestic hot water service was maintained to the development for the duration of construction. The development’s three existing indirect domestic water heating systems and their associated steam heat exchangers were to be replaced with high efficiency, gas-fired condensing domestic water heaters with storage tanks. The intent was to decouple the domestic water heating systems from the central boiler plant.

Solutions

H2M provided engineering investigative and design services for the replacement of the central boiler plant and decoupling of three domestic water heating plants at the Fiorentino Plaza Housing Development.

The design of the new domestic water heating systems included new hot water recirculation pumps, storage tank circulator pumps and domestic hot water tempering valve stations. The installation of new natural gas services was coordinated with the local gas utility to serve the new domestic water heaters. Replacement of sump pumps and condensate return units located in each of the seven remote Mechanical Equipment Rooms was also included in the design.

The electrical design included new power and control wiring for all new equipment, replacement of main distribution panels and the installation of new high efficiency LED lighting.