Changes in and additions to the 2017 edition of NFPA 70: National Electrical Code (NEC) have an impact on commercial and industrial facilities.

Learning objectives:

- Understand the basics of NFPA 70: National Electrical Code (NEC).

- Know that NEC is updated every 3 years, and understand the changes to the 2017 edition.

- New articles were introduced recently; learn about them here.

Do engineers need to know NFPA 70: National Electrical Code (NEC)? Certainly! NFPA 70 is adopted into law in every state in the country, as well as in many foreign countries.

In Article 90.1, the first paragraph of the NEC, it is clearly stated that it is not a design document. However, it is the basis of every electrical design and is the minimum standard that will provide a safe and legally acceptable design. While the NEC may allow an engineered system that goes beyond the requirements of the code to provide more efficiency and convenience, it does not require efficiency or convenience.

The NEC assumes the user has some training in and at least a basic understanding of electrical principles. This typically is not a concern for electrical engineers, but it may present a challenge for those expanding into areas of design and construction in which they are not familiar.

The NEC is a consensus document with changes proposed, evaluated, and reviewed by numerous members along with additional public input for each change that appears in the document. Every 3 years, the NEC introduces new safety concepts. Sometimes, it even forces the industry to bring new products to market that are in development but proceeding more slowly than the NFPA consensus feels is reasonable. These new products will cause development of new procedures for installation and new requirements for design.

New NEC articles

The 2017 edition of the NEC has introduced five new articles. These include some interesting and sometimes confusing requirements that affect electrical design. The new articles are briefly discussed below:

Article 425—Fixed Resistance and Electrode Industrial Process Heating Equipment: Previous versions of the NEC included requirements for space heating, pipeline heating, and deicing/snow melting, but did not address electric boilers or other process heating. This new article fills this void. Now there are requirements that provide the minimum for a safe installation.

Article 691—Large-Scale Photovoltaic (PV) Electric Power Production Facility: Large PV systems have unique safety and operational features because the power source (the sun) is not controllable. This new article addresses these complications in large PV arrays not controlled by a utility.

Article 706—Energy Storage Systems: With the proliferation of nonutility energy-production facilities, there also has been an increase in energy storage to supplement the production, so the time of energy use can be coordinated with the cost of power. This new article addresses the safety concerns for having a large number of storage batteries in close proximity.

Article 710—Stand Alone Systems: Most places in the U.S. now have access to utility-provided electricity, but not everywhere. Where utility power is not available, or where someone chooses not to connect to the utility, the electric installation now has criteria directed specifically to it.

Article 712—Direct Current Microgrids: Dc microgrids connect dc power supplies and loads. The sources may be solar systems, wind power systems, fuel cells, or batteries. Many types of loads now have dc versions, including lighting and motors. Because of the limited effective transmission distance of dc power, these microgrids are limited to small areas.

Changes to existing articles

Along with the new articles, there were more than 4,000 public inputs (requests for changes) and more than 500 changes to existing requirements. Some of these changes include:

A change to the definition of “readily accessible” clarifies that it is permissible to lock electrical equipment or electrical rooms to limit access by unauthorized personnel (Article 100).

Article 110.16(B): Service equipment rated 1,200 amp and larger must be marked with arc flash data. The data required will require arc flash calculations, and it should be clear in the contract who must provide this data. Some owners want to see the data prior to the end of design so changes to the design can be made to lessen the arc flash. Calculations not based on the actual equipment installed and actual conductor types and lengths are always an approximation. But waiting for the contractor to install equipment and conductors that do not meet arc flash requirements can result in large change orders. Arc flash labels can be factory- or field-applied. The label contents are defined along with the new Article (110.16(B)). Because arc flash is a huge safety concern, the 2017 edition continues the effort to minimize arc flashes with requirements and methods for reducing the energy that flows through fuses and circuit breakers rated at 1,200 amp or higher.

Continued expansion of ground-fault circuit interrupter (GFCI) protection includes single-phase receptacles up to 50 amp and 3-phase receptacles up to 100 amp. This expanded protection is required for nonresidential installations nits where voltage doesn’t exceed 150 V to ground and in locations listed in 210.8(B). GFCI is also required for lighting outlets in crawl spaces, the reason being there is little possibility of falling away from an electrical fault while in a crawl space. Also, any person in a crawl space is most likely well-grounded.

The locations requiring arc fault and tamper-resistant receptacles also have expanded. Arc fault receptacles have the ability to reduce fires that result from arcing at conductor connections. The locations where they are required have been slowly increasing since their inclusion in the code. Tamper-resistant receptacles protect people, particularly children, from electric shock and arcing flash burns by reducing the possibility of inserting metal objects into a receptacle. Locations where they are required, usually where children might not be closely supervised, have been increasing each code cycle.

The number of receptacles in meeting rooms must meet minimum requirements based on the size of the room. The receptacles can be located to suit the designer. Also, rooms between 225 and 760 sq ft must have floor receptacles located at least 6 ft from any wall.

When conduits are run across a rooftop, previous editions of the NEC had a table listing derating factors based on their height above the roof. The reason for this was a study showing that the conductors in the conduits were exposed to higher temperatures because of the heat radiating from the roof. More recent studies have shown the initial study was flawed and the conductors are not subjected to an appreciable temperature gradient. The 2017 edition has removed the table and the requirement for derating, except if the conduit is less than 7/8 in. above the roof.

Many types of power distribution and control equipment must now be marked with the short-circuit rating, and documentation must be available to inspecting authorities showing the available short-circuit current at the installation location. Making sure all equipment is capable of withstanding available short-circuit current provides a measure of personnel protection and prevents extreme damage to equipment. Having the documentation, calculations, and equipment submittals on hand may require much more extensive calculations than previously. This may require more expensive versions of the calculation programs.

NEC chapters

The NEC is divided into nine chapters; chapter nine is tables. Each has different functions and addresses different aspects of electrical installation.

Chapter 1—General is the basis for the application of the code. Terms that are used by more than one article are defined in Article 100; terms that are in common use and not given special meanings within the electrical trade are not defined. Also included in Chapter 1—in Article 110, Requirements for Electrical Installations—are requirements for listing and marking, working space, and guarding of live parts. A strong working knowledge of this chapter is fundamental to understanding the code.

Chapter 2—Wiring and Protection contains the requirements for branch circuits including identification, protection of conductors, GFCI protection, arc fault protection, and bonding and grounding. Proper grounding and bonding is one of the most important items in the code for the protection of wiring, equipment, and most important, people. Nothing else does as much to channel voltage from faults away from people and equipment and provide stable power for the operation of equipment, particularly electronics. It is interesting that surge arrestors and surge protective devices are included in Chapter 1 and not Chapter 6—Special Equipment. The reliance on proper grounding for these devices to perform their function is a big consideration in this location.

Chapter 3—Wiring Methods and Materials contains requirements for physical protection of conductors inside buildings and structures, underground, and outside aboveground . It has the most used table in the code: 310.15(B)(16), Conductor Ampacity Up to 2,000 V. The values in this table have to be modified by application of derating and correction factors elsewhere in Article 310.15.

Chapter 3 also describes conduit and conductor types and gives requirements for their use. It contains requirements for raceways, support structures, and miscellaneous materials and equipment for carrying current or conductors.

Chapter 4—Equipment for General Use includes requirements for flexible cables, distribution and control panels, switches and receptacles, lighting, electric heating, motors, air conditioning, generators, transformers, and similar equipment. The article on motors is long and detailed, as it covers a large portion of the work in commercial and industrial establishments. Other articles in Chapter 4 may not be as long, but the chapter is only concerned with the special requirements for the equipment included. All the general requirements of Chapters 1 through 3 also apply.

Chapter 5—Special Occupancies includes Articles 500 through 506, which provide important details for determining if an area is a hazardous (classified) location and identifying the particular classification. These details are supplemented by information from other NFPA standards, which are referenced in these articles. Included are requirements for wiring, equipment, and safety features necessary to prevent fires and explosions in hazardous areas. Like the grounding requirement in Chapter 2, these articles contain requirements critical for the protection of facilities and people.

Articles 511 through 516 deal with types of facilities that frequently, but not always, are classified areas or contain classified areas. Application of the requirements depends on the proper use of the area-classification definitions. Researching the standards referenced in Articles 500 through 506 will help in the proper classification of the areas.

Articles 517 through 555 deal with occupancies and building types that have special requirements because of their use. The requirements vary depending on the different types of structures, the number of occupants, and in the case of agricultural buildings, the type of occupant. There also are differences based on whether the potential danger is to people or to the structures and equipment.

Article 590 is for temporary installations. The safety requirements for these installations are often overlooked because “they’ll only be here for a short time.” Actually, these installations result in a disproportionate number of electrical incidents. The requirements are similar to permanent installations, but some requirements are relaxed and others are stricter.

Chapter 6—Special Equipment covers a variety of equipment: signs, office furnishings, cranes, elevators and lifts, vehicle, truck-charging stations, welders, audio equipment, information technology equipment, pipe organs, x-ray equipment, swimming pools, PV, wind, and fuel cell power production, plus other similar equipment. There are different requirements for the installation of specific varieties of equipment, but all are based on the general requirements of Chapters 1 through 4.

Article 695 addresses fire pumps; the requirements for these pumps are much different than for other types of pumps. The main concern is to keep the pump running whenever it is needed, regardless of the potential or actual damage to the pump or the pump’s electrical system. If the pump is needed to provide protection during a fire, then the damage to the pump or its electrical system is a minor problem as long as the pump continues running.

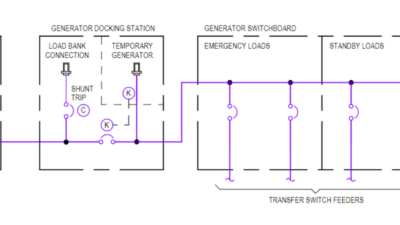

Chapter 7—Special Conditions also covers a variety of items, but these are systems and cables: emergency systems, standby systems, interconnected power production, energy storage, small power-production systems, various specialized cable systems, and fire alarm systems. Emergency systems and fire alarm systems have obvious importance for personnel safety and building protection, but other systems also have a considerable impact on safety .

Critical-operations power systems (COPS) are vital for infrastructure that could be necessary to prevent disruption of national security, public health, the economy, or other governmental requirements. Failure of a COPS could result in drastic consequences; therefore, proper installation is vital. Energy-storage and small power-production systems contain a large amount of power in a small facility. Failure of these systems could result in large energy releases that could be destructive to buildings or people.

Chapter 8—Communications Systems stands alone. None of the requirements in Chapters 1 through 7 apply to Chapter 8 installations unless they are referenced in Chapter 8. Chapter 8 covers requirements for communications systems, TV and radio systems, and broadband communications systems. Many of the requirements of Chapters 1 through 7 that are not referenced are actually copied into Chapter 8 with modifications to fit communications circuits. For instance, grounding of raceways and cable sheaths is more detailed than similar requirements in the grounding article in Chapter 2. Some are stricter and others are more relaxed; i.e., raceway-fill requirements do not apply to Chapter 8 installations.

Annexes and tables

Chapter 9 tables include tables for raceway dimensions, dimensions of raceway bends, dimensions of conductors, conductor properties, and power-source limitations. The information in these tables is necessary for some of the calculations needed to comply with requirements in other chapters.

Annexes A through J contain information that makes it easier to comply with some of the requirements that otherwise would require tedious calculations. The annexes do not have code-enforceable requirements, but complying with the annexes will generally ensure compliance with the requirements of Chapters 1 through 8. Some of the information is excerpted from other standards, so it is available without purchasing another document. This enables the installer to comply with NEC requirements that reference other standards.

So, does an engineer need to know the NEC? Absolutely! The NEC provides the foundation for a design that meets the latest standards and that can be used to build a safe and effective system. For a system that is more efficient and more convenient for the operators than the NEC demands, the engineer needs to know where to modify the design to obtain that efficiency or ease of operation and still remain within the parameters set by the NEC. The NEC is the code—and the law—adopted by statute in every state. Study it not only for your own protection, but for everyone else’s as well.

Victor Ammons is a senior electrical engineer and electrical discipline leader at Jacobs. Ammons started work at an early age in a family-owned contracting business and now has more than 50 years of contracting and engineering experience.