Electrical safety is paramount at this Virginia water treatment plant

A project that was designed with safety in mind is Loudoun Water’s Trap Rock Water Treatment Facility in Virginia. This design incorporated several significant safety features:

- All distribution equipment within the facility, including switchgear and motor control centers, were designed with main-tie-main bus configurations to provide redundancy and ease of maintenance. This allows maintenance to be performed on the distribution equipment without interrupting process operations.

- The medium-voltage switchgear was provided with a mimic panel located elsewhere in the electrical room (Figure 3). The mimic panel contains the switchgear’s breaker controls and indications, the programmable logic controller, which controls the automatic transfer control system, the annunciator and controls for the facility’s generator and a human machine interface, which allows operators to view and set parameters within the system. By moving the physical controls from the switchgear to a remote 120-V-only mimic panel, the design allows for safe operation of the switchgear. This also allows for easy maintenance of the low-voltage controls systems without exposing personnel to the medium-voltage components. The medium-voltage switchgear was also provided with a remote racking device to allow for the circuit breakers to be removed remotely with minimal hazard to electricians.

- The low-voltage switchgears were provided with ARMS switches. This increases the safety of the low-voltage switchgear by allowing for decreased arc flash hazards when working on the equipment. Regardless of the position of the ARMS switch, employees should still wear the appropriate PPE when working on the switchgear.

- All electrical rooms are designed with extra space to allow for easy and safe maintenance of electrical equipment (Figure 2).

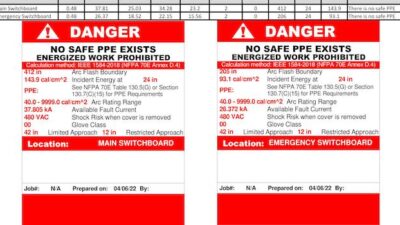

- Arc flash studies were performed during the initial construction of the facility using the incident energy analysis method and all equipment was labelled on-site. Loudoun Water is performing follow-up arc flash reanalysis and updating the arc flash labels to make sure employees are informed of the hazards present at each distribution equipment.