Case study: Duct-mounted UV system

A duct-mounted UV system experiment showed bacteria was killed

To test the feasibility and effectiveness of a duct-mounted ultraviolet system, Smith Seckman Reid commissioned a test where an aerosolized water solution of biosafety level 1 Staphylococcus epidermis bacterium was introduced into the ductwork airstream and evaporated into the airstream before passing each device, then samples were collected and incubated for seven to 10 days.

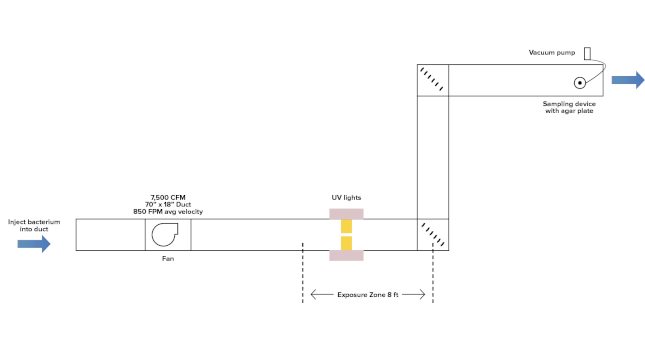

The experiment protocol involves capturing five separate samples and determining the existence and amount of the control bacteria (Staph. epidermis). To create a single pass system scenario for the experiment, approximately 50 feet of 70×18-inch ductwork was assembled in a “Z” shaped orientation (two 90-degree elbows) within a warehouse. Installing a 5-horsepower fan to provide 7,500 cubic feet per minute of airflow at 850 feet per minute through the duct system was used (see Figure 4).

This velocity exceeds the desired feet per minute as standardized by ASHRAE Standard 185.1: Method of Testing UV-C Lights for Use in Air-Handling Units or Air Ducts to Inactivate Airborne Microorganisms; this was intentional. If the engineering team could show that installing a UVC system in low-pressure ductwork that exceeded ASHRAE 185.1’s desired velocity of 500 feet per minute, then the results would support this type of installation in other low-pressure ductwork if space within the air handling unit was not sufficient.

For the UV light to be effective at this velocity or greater, the intensity of the UV light was calculated for a k value (inactivation rate constant) of 67 joules per square meter and an exposure time of 0.5 seconds. After seven to 10 days, the results culture plate showed no presence of the bacteria, indicating a high level of effectiveness. Because the dosage to “kill” the bacteria is many times greater than what is required for the COVID-19 or influenza virus, this duct-mounted system could be expected to be effective on those pathogens, as well.

However, as noted above, the intensity or exposure time would need to be increased to obtain the dosage required to mitigate spread of mold.

Figure 4: Installing a 5-horsepower fan to provide 7,500 cubic feet per minute of airflow at 850 feet per minute through the duct system was used. Courtesy: Smith Seckman Reid

Do you have experience and expertise with the topics mentioned in this content? You should consider contributing to our CFE Media editorial team and getting the recognition you and your company deserve. Click here to start this process.