This article explores key technical, operational and design considerations in comparing boilers and heat pumps for hydronic heating systems, with a focus on climate adaptability, efficiency and cost.

Learning objectives

- Understand the fundamental differences between boilers and heat pumps: Readers will be able to explain how boilers and heat pumps operate, including their energy sources, heat transfer mechanisms and typical hydronic system applications.

- Evaluate the suitability of each system based on climate, building type and load profile: Readers will learn how to assess which system is more appropriate for a given project by considering factors such as outdoor temperature, heating demand, system efficiency and retrofit constraints.

- Identify the environmental and economic impacts of transitioning from boilers to heat pumps: Readers will gain insight into the carbon emissions, operating costs and potential incentives or regulatory drivers influencing the shift toward electrification and heat pump adoption.

Heat pump insights

- Hydronic heating systems have traditionally relied on boilers for reliable, high-temperature performance, but growing decarbonization efforts and electrification policies are shifting focus toward electric heat pump alternatives.

- As the electric grid becomes cleaner and heat pump technologies advance, engineers must carefully compare the performance, design complexity and retrofit compatibility of boilers and heat pumps to meet modern building efficiency and carbon reduction goals.

Hydronic heating has long been a dependable solution for commercial buildings, delivering centralized comfort and precise control. Traditionally, boilers have served as the cornerstone of these systems, providing the primary source of thermal energy.

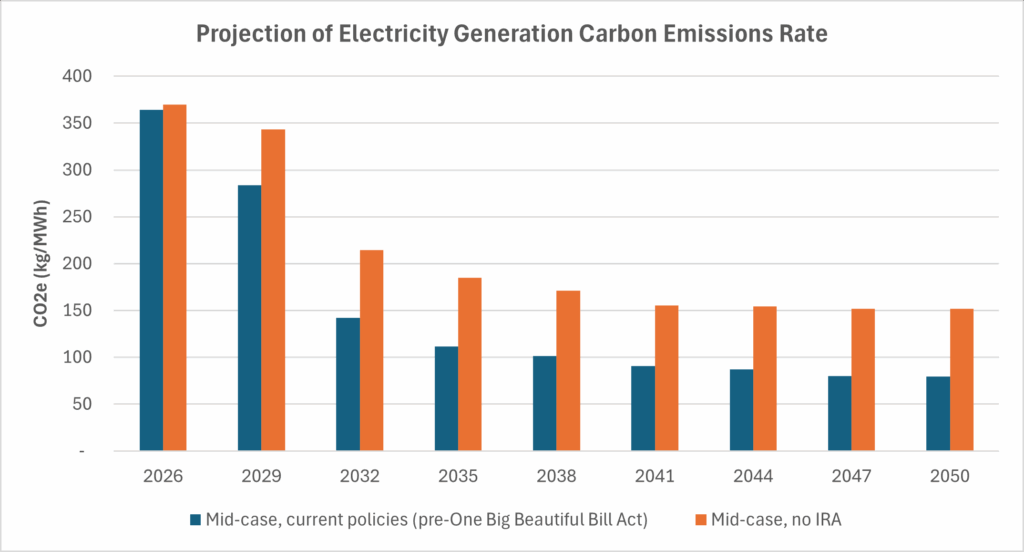

But as performance standards tighten, electrification policies expand and fossil fuel markets fluctuate, electric heat pumps have gained traction, reinforced by the rapidly decarbonizing U.S. electric grid. Per the National Renewable Energy Laboratory (NREL) Standard Scenarios datasets that contain modeled hourly data for a range of possible futures in the U.S. electricity sector through 2050, the carbon intensity of electricity generation is projected to decline by 50% over the next decade (see Figure 1) as coal-fired power plants are replaced by renewable sources like solar and wind.

A cleaner grid enhances the environmental performance of electrified buildings, positioning heat pumps as a lower-emission substitute for fossil fuel systems. However, their performance depends on climate, system design and retrofit compatibility. As buildings strive to cut carbon, boost efficiency and modernize infrastructure, engineers must be aware of the differences between traditional boilers and modern heat pump technologies in hydronic applications.

Boilers: conventional and capable

In combustion-based systems, heat is produced by burning fuel, most commonly natural gas, within a combustion chamber and transferring that heat through a heat exchanger to generate hot water or steam. In contrast, electric boilers operate without combustion, converting electrical energy directly into heat using resistive heating elements or electrodes to generate hot water.

Boiler systems offer several advantages. They are highly reliable in cold climates, maintaining full heating capacity regardless of outdoor temperatures. Their ability to deliver high supply water temperatures up to 180°F makes them compatible with legacy systems such as radiators and older hydronic coils. Integration is straightforward due to well-established piping standards, control logic and loop configurations, making boilers a mature and familiar technology for both retrofit and new construction projects.

Additionally, gas-fired boilers generally have lower upfront capital costs than heat pumps and can deliver high thermal outputs from a compact mechanical room footprint.

However, these systems also present challenges. Boilers are less energy efficient than heat pumps and gas-fired boilers emit carbon dioxide (CO₂), nitrogen oxides (NOₓ) and other pollutants, contributing to greenhouse gas emissions and local air quality concerns.

Hydronic boiler design considerations

Hydronic boiler systems are widely understood and familiar to designers, contractors and facility operators. As a mature and well-established technology, boilers are generally straightforward to design and integrate, especially when compared to the more complex requirements of heat pump systems. However, to maximize efficiency and future-proof the system for potential integration with heat pumps, thoughtful design considerations are essential. Condensing boilers achieve peak efficiency when return water temperatures stay below the dew point of the flue gases — typically around 130°F — allowing for latent heat recovery and improved thermal performance.

Designing the hydronic distribution system around this 130°F supply temperature not only supports condensing operation but also aligns with the operating range of conventional subcritical heat pumps. This compatibility provides flexibility for future decarbonization retrofits and enables smoother integration between boiler and heat pump systems. When operating at lower supply water temperatures, careful selection of heating coils becomes critical.

Because boiler manufacturers often optimize their systems for a 20°F temperature differential (delta T), achieving this delta T with lower-temperature hot water may require larger or multirow terminal unit coils to maintain performance. Controls also play a vital role in system efficiency and reliability.

ASHRAE Guideline 36: High Performance Sequences of Operation for HVAC Systems includes detailed control diagrams and sequences for various boiler plant configurations, covering boiler staging, setpoint adjustments, pump staging and speed control, bypass valve operation, alarms and automated fault detection and diagnostics. These sequences were introduced in the 2021 edition of the guideline. While some boiler manufacturers and operators may prefer to use a master staging controller provided by the manufacturer, both approaches — centralized or manufacturer-supplied — can be effective, with only minor differences in control logic.

Heat pumps: electrified and efficient

Heat pumps transfer heat rather than generate it, using the vapor-compression cycle to move heat from a cooler source to a warmer sink. In general, heat pumps fall into two primary categories based on their heat exchange medium. Air-source heat pumps (ASHPs) transfer heat from building’s hydronic heating or cooling loop to the ambient air.

In contrast, water-source heat pumps (WSHPs) transfer heat from the building’s hydronic heating or cooling loop to a source water loop whose temperature is regulated by auxiliary equipment such as boilers, cooling towers, geothermal fields or wastewater heat exchangers. Generally, in both cases the heat pumps are engineered as modular equipment, allowing multiple smaller units to be installed in parallel rather than relying on a single large unit, providing flexibility, scalability and redundancy.

These systems offer several advantages. They are highly energy efficient, typically 2.5 to 4 times more efficient than boilers and most are reversible, providing both heating and cooling from a single system. Heat recovery chillers (a type of WSHP) can simultaneously heat and cool the buildings respective hydronic loops, achieving coefficients of performance (COPs) between 5.0 and 7.0 when loads are balanced, which reduces reliance on auxiliary heating and enhances year-round energy performance.

Additionally, heat pumps eliminate onsite combustion, which reduces emissions, improves indoor air quality and removes the need for flue systems.

Despite these strengths, heat pumps also present challenges. Installation costs can be high, due to complex design and infrastructure requirements, particularly for geothermal systems (however financial incentives such as the Inflation Reduction Act Investment Tax Credit can offset the additional cost).

In colder climates, ASHPs experience reduced capacity and efficiency and defrost cycles can further diminish effective output. Moreover, the lower output temperatures of conventional subcritical heat pumps, typically 130°F, may not align with the needs of legacy hydronic systems that were designed for higher temperatures in retrofit applications. This mismatch may necessitate building upgrades, such as envelope upgrades, replacing legacy hydronic space heating equipment, integrating more sophisticated transcritical heat pumps capable of reaching 180°F supply water temperatures or supplementing with a boiler for backup heating.

Heat pump design considerations

Effective heat pump system design begins with a clear understanding of the key parameters that will influence decision-making. These include the owner’s carbon reduction goals, sustainability targets, project budget and local utility rate structures. It’s also important to evaluate the projected carbon intensity of the regional electric grid, as this will shape the long-term emissions profile of electrified systems. Compliance with applicable energy and green building codes — such as the International Energy Conservation Code and its Zero Code Appendix — must be factored in, along with any targeted sustainability certifications or rating systems.

Site-specific conditions, such as access to wastewater mains or the thermal conductivity of the soil (which affects the feasibility of ground heat exchanger installation) also play a critical role. Finally, assess whether the system must provide heating during a utility power outage, as this will influence equipment selection, backup strategies and overall system resilience.

Designing an effective heat pump system requires a thorough understanding of the building’s thermal energy flows to enable strategic redistribution of heat where and when it’s needed. This level of precision is especially important when integrating components like ground heat exchangers and thermal energy storage.

To support accurate system sizing and performance modeling, it is essential to develop detailed hourly heating and cooling load profiles based on robust annual simulations. Relying on default profiles in load calculation software can be misleading, as these often significantly overestimate internal gains from occupancy and plug or process loads. Accurate modeling early in the design process is critical to optimizing heat pump performance and ensuring long-term operational success.

Reversible heat pumps should be sized to meet the greater of a building’s heating or cooling demand. When there is a significant disparity between peak heating and cooling demands, designers should consider employing multistage configurations using multiple circuits or modular units to optimize system performance and mitigate short cycling to avoid premature equipment failures.

Incorporating ASHPs equipped with variable-speed inverter compressors can enhance part-load efficiency due to their superior turndown capabilities. Additionally, integrating thermal energy storage can further improve operational flexibility and energy efficiency.

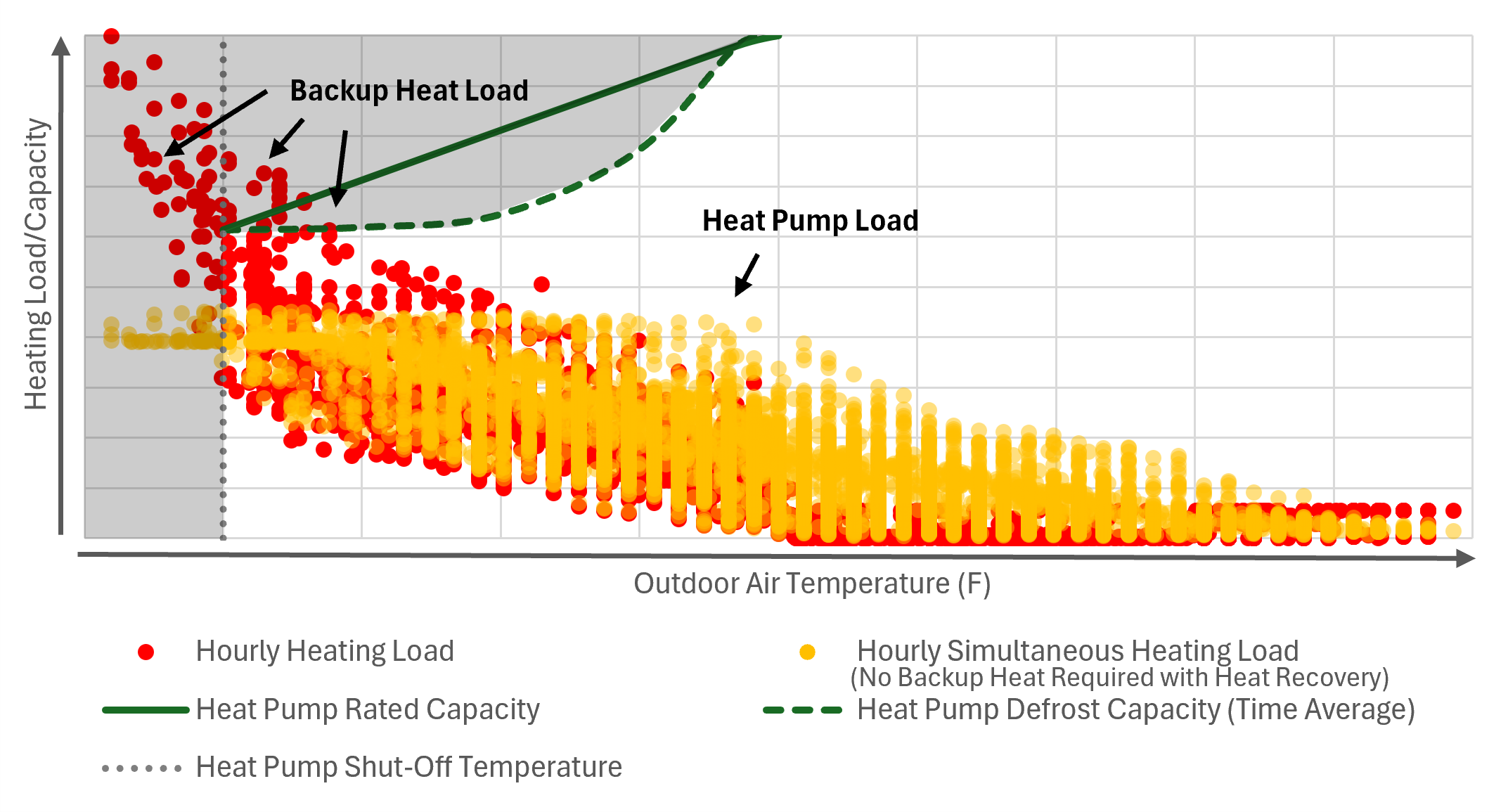

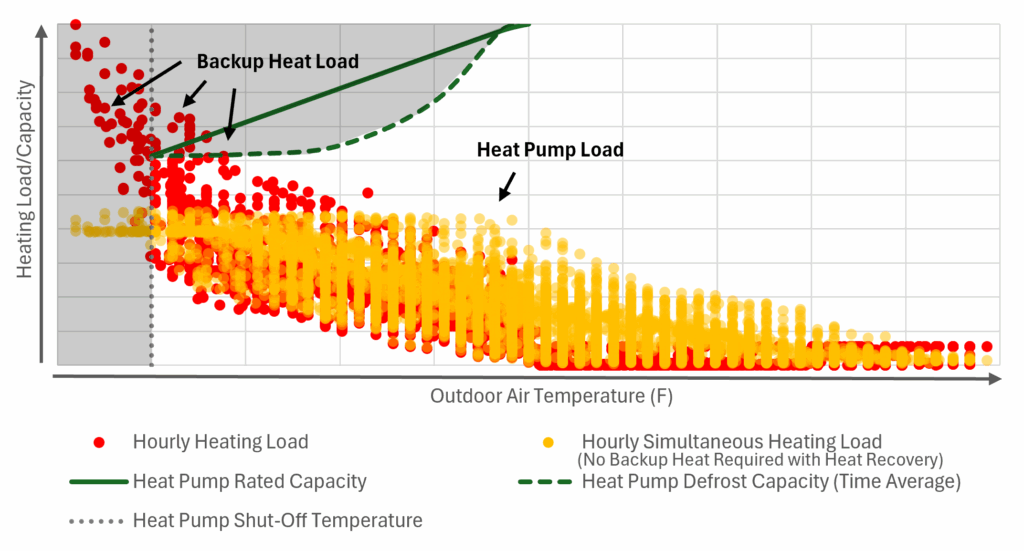

For ASHPs, it’s critical to consider local ambient temperatures, especially in colder climates (ASHRAE Climate Zones 5 to 8), where capacity and efficiency can drop significantly. This often requires upsizing equipment, using staged compressors or adding supplemental heat to meet peak loads.

Additionally, at freezing temperatures, frost buildup on the outdoor coil can obstruct airflow and further reduce performance. To mitigate this, ASHPs periodically enter a defrost cycle — temporarily reversing operation to melt accumulated ice — which can interrupt heating, cause short cycling and increase energy use during peak demand periods.

To maintain comfort and reliability in subfreezing temperatures, engineers should:

- Use weather data and hourly load analysis to inform capacity planning.

- Use cold-climate rated ASHPs, often certified by the Northeast Energy Efficiency Partnerships.

- Add buffer tanks to store thermal energy during defrost cycles.

- Deploy ground- or water-source heat pumps, which rely on more stable temperature sources.

- Integrate hybrid systems, with boilers or electric resistance heaters as backup.

In WSHP systems, sizing should be based on the source loop’s expected maximum and minimum temperatures, as maintained by auxiliary equipment. In a conventional source water loop system, a boiler supplements heat during periods of heating demand, while the cooling tower rejects excess heat during cooling periods, maintaining a loop temperature commonly between 55°F and 90°F.

Ground-source (geothermal) systems use vertical boreholes or horizontal ground loops to use the earth as a thermal reservoir, absorbing and releasing heat seasonally. These systems typically operate over a broader temperature range (e.g., 40°F to 90°F). Auxiliary equipment such as boilers, cooling towers or even ASHPs may be incorporated to balance seasonal loads and maintain loop temperatures.

Wastewater heat recovery systems leverage the relatively stable temperature of wastewater, typically around 70°F, as a consistent and renewable heat source or sink. This approach is particularly effective in dense urban environments or mixed-use developments where wastewater flow is continuous and predictable, enabling high system efficiency and reliable thermal exchange.

Simultaneous heating and cooling loads offer a valuable opportunity for heat recovery via heat recovery chiller. Heat rejected from the cooling loop is used as a free heat source for the heating loop, improving overall system efficiency and, in ASHP applications, reducing reliance on ambient air temperature.

When sizing ASHPs to meet peak heating loads is prohibitive due to cost, footprint or other constraints, a hybrid system with backup heating is a practical alternative. In this configuration, heat pumps cover the base load during milder conditions, while boilers provide backup heat during extreme cold.

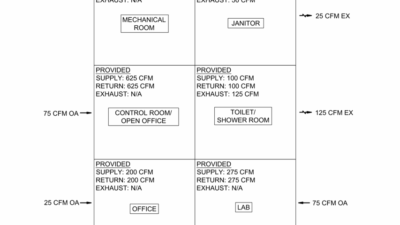

In some cases, heat pumps designed for just half the peak heating capacity can still satisfy most of the total annual heating demand due to the dearth of hours where the heating load exceeds the heat pump capacity. The use of electric boilers for backup heating is a balance between space constraints, equipment first cost and electrical infrastructure cost (see Case study: Evaluating heating plant configurations in a low-carbon grid region).

Engineers should consider the following when choosing the backup heat source:

- Simultaneous heating load can be excluded for sizing partial capacity backup heat.

- Compare the cost of a ground loop against the cost of the electrical upgrade required for electric boiler backup heat.

- For retrofits, existing equipment that is operational can be used as the backup heat source.

Additional considerations for plants using modular heat pumps:

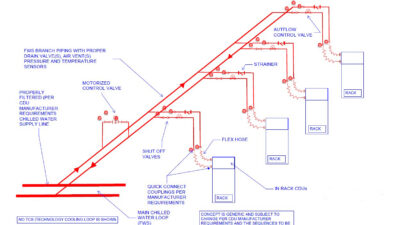

- The use of glycol solutions is often necessary for freeze protection in heat pump applications. This may necessitate the use of heat exchangers to decouple central plant loops from building distribution loops.

- Design a primary-secondary system configuration with the primary pumps controlled to maintain a constant differential pressure across the modular heat pump and secondary pumps controlled to maintain system differential pressure. Note: the use of flow-based control of primary pumps is not recommended due to the instability created during stage-up and stage-down events.

- Locate the temperature sensor used by the heat pump’s packaged controls in the secondary loop downstream of the decoupler pipe, but upstream of the secondary pumps to ensure the packaged controller recognizes when secondary flow exceeds primary flow.

- Provide buffer tanks on the supply line of the secondary loop (to stabilize heating hot water supply temperature ) and the return line of the primary loop (to stabilize the heat pump entering water temperature and avoid trips).

- Locate the minimum flow bypass valve at a distant point in the system to increase effective system volume.

- Specify the minimum flow bypass valve to be pressure dependent and include a 30-second actuator.

- Coordinate closely with the heat pump manufacturer on system configuration and controls design.

- Finally, expect a longer and more involved commissioning/tuning process. Modular heat pump products are sensitive.

Life cycle analysis

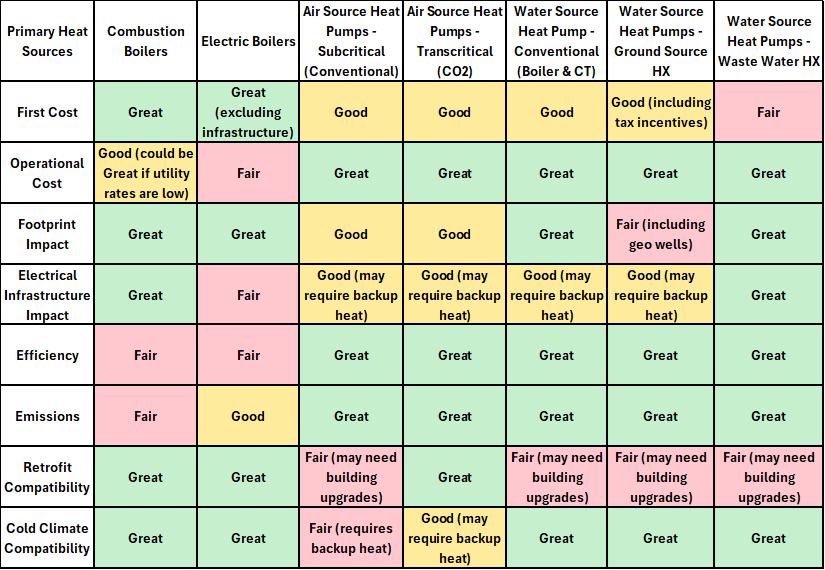

To ensure heating, ventilation and air conditioning (HVAC) systems are both cost-effective and aligned with long-term sustainability goals, it’s essential to conduct detailed analysis and life cycle cost and carbon assessments early in the design process. Key system decisions, such as whether to use ground or wastewater heat exchangers, water-source or air-source heat pumps, electric or gas boilers, thermal storage or hybrid configurations, can often be evaluated once the building program is defined, even before architectural design begins.

Early decisions are critical for accurately sizing electrical infrastructure, allocating space for equipment and integrating sustainability features. Delaying these choices into later design phases can disrupt coordination, increase construction costs and reduce profitability for project teams. Comprehensive modeling should include:

- Initial capital costs (with and without incentives)

- Operational savings from improved energy efficiency

- Maintenance and replacement cycles

- Carbon intensity reductions over time

- Whole-building emissions over a 20- to 30-year period

- Penalties or compliance costs associated with emissions or fossil fuel use in jurisdictions with building performance standards or carbon caps

This approach allows stakeholders to evaluate not just short-term affordability but also long-term resilience and environmental impact.

Federal and state policies are accelerating the shift to all-electric HVAC systems through financial incentives and regulatory support. The Investment Tax Credit, for example, offers substantial tax benefits for ground source heat pump installations, while state and utility rebate programs further improve the economics of electrification. These incentives can be explored through resources like the Database of State Incentives for Renewables & Efficiency (DSIRE).

As the building industry moves toward decarbonization and energy efficiency, the choice between heat pumps and boilers is a strategic decision with long-term implications. Ultimately, the choice depends on a building’s specific load profile, climate zone, infrastructure and long-term sustainability goals.