Integrated design practices allow a middle school to achieve net-zero energy.

Learning Objectives

- Know which metrics to use to establish baseline energy numbers for a building.

- Understand the four things needed to design a net-zero energy building (NZEB).

- Gain insight into the interdependency on multiple building systems in an integrated design.

The Hood River Middle School Music and Science Building (HRMS) building was designed by Opsis Architecture, Portland, Ore., with mechanical, electrical, plumbing (MEP), and energy consulting provided by Interface Engineering.

With the emergence of nationally established building performance targets and rising concerns over climate change, the push to design and construct net-zero energy buildings (NZEB) is stronger than ever. To achieve this ambitious goal, teams must eschew traditional design practices and use an integrated design process that seamlessly combines architectural elements, site features, and engineered systems as a cohesively operating whole.

This article aims to summarize some of the key components of the integrated design process and highlight the Hood River Middle School (HRMS) Music and Science Building that was designed using this concept. The building opened in the fall of 2010 and was constructed by Hood River (Ore.) County School District using funding from the May 2008 construction bond. The building houses a music classroom, music practice rooms, a new science lab with an attached greenhouse, and associated offices and support space. The building has been operational now for 3 years and has achieved net-zero energy.

At the start of any project and particularly a net-zero energy project, it is critical to determine baseline energy numbers to establish a benchmark for simulation and design purposes. The most widely referenced database of energy metrics is the Commercial Buildings Energy Consumption Survey (CBECS), which is maintained by the Dept. of Energy. It is a national sample survey that collects energy usage and building characteristics on the stock of commercial buildings in the United States.

Energy consumption is available normalized as an energy use index (EUI) in units of kBtu/sq ft/year, which can be broken down into different end uses (heating, cooling, lighting, etc.). The Target Finder tool provided through the Energy Star website is a great tool for determining a building’s baseline energy rating. For the HRMS building, a baseline EUI of 52 kBtu/sq ft/year was determined with the major energy end uses being heating and lighting.

NZEB needs four things

There are four steps in the integrated design concept that are essential in yielding a NZEB: harnessing natural resources at the site, conservation through building elements, use of renewable energy resources, and measurement and verification (M&V) of intent.

Using site-available natural resources is essential and one of the most cost-effective strategies for achieving net-zero energy. Thus, it should be considered first in the design process. The HRMS project integrates multiple natural resources into the building and systems by using the earth, water, wind, and the sun in various forms to achieve its performance.

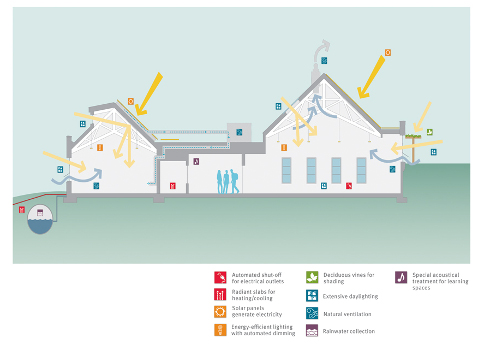

Wind drives a natural ventilation system that combines low and high clearstory windows and rooftop ventilators to allow cross and stack ventilation. A red light/green light indicator informs building occupants when outside temperatures are favorable for natural ventilation, which engages students in the management of the building’s energy use.

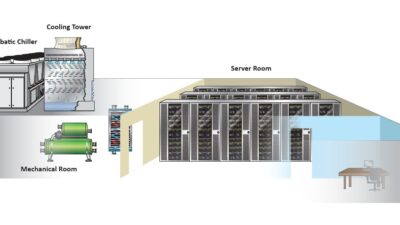

The earth provides one of the most efficient heat sources for the building’s main HVAC system, a geo-exchange system of tubing that is horizontally looped 10 ft under the school’s adjacent soccer field. The tubing is connected to two internal water-to-water heat pumps that feed radiantly heated and cooled slabs in the building.

An additional energy source for summer cooling comes from a portion of an adjacent stream. The district uses the stream’s snow melt runoff for irrigation during the region’s dry summers, which happens to coincide with the need for cooling during the summer months. Thus, the irrigation water is simply diverted through a heat exchanger when there is cooling demand. This cool water can be circulated through the building’s radiant floor slabs to provide cooling without using a refrigeration process.

Due to the proximity to the Columbia River Gorge, renowned for its windsurfing, it was assumed early on that wind-powered turbines could be an effective renewable energy source. However, an analysis of the micro climate of the site proved wind energy was not as cost-effective as solar. The sun provides renewable energy to the building in several different forms, which will be discussed below.

Energy efficiency

After analyzing the available site natural resources, the next step is to focus on conservation energy measures within and around the building. This step is where an integrated design process can provide the means to achieve net-zero energy and stay within budget. Combining architectural and engineered elements is the most cost-effective way to produce deep energy savings. Energy conservation measures can be broken into two separate categories: passive and active systems.

Arguably the most important passive system for any NZEB is the envelope. Careful attention was paid to this on HRMS, with R-38 rigid insulation (with lapped layers to avoid gaps) on the roof and R-15 insulation under the radiant slab on grade. The insulated concrete formwork (ICF) walls achieve an overall R-value of 25 and provide excellent thermal mass buffering against Hood River’s seasonal temperature swings. This type of wall uses polystyrene foam interlocking blocks to construct the form work for the walls. Concrete is then poured in stages into the formwork with rebar used for added structural stability. The forms are then left in place and provide the building’s thermal protection layer. Due to their monolithic nature, ICFs can drastically reduce air infiltration and thermal bridging with proper detailing. Last, triple glazing helps reduce heat gain and loss at the windows. The triple-glazed windows are set in wooden frames, which provide a higher level of thermal resistance than more common aluminum frames.

Daylighting is highly recommended for any net-zero energy project to reduce one of the highest energy end uses and is an example of a pseudo-passive strategy. While it takes an integrated control system to dim the electric lights in a space, the sun provides lighting passively through the windows or skylights. To achieve the optimum level of daylight in the HRMS classrooms, the project team performed multiple detailed daylighting studies, balancing the results with those of the energy model. The resulting design combines translucent skylights, clerestory windows, and traditional windows with deciduous vines for seasonal shading allowing views in multiple directions from most building locations. Light-colored acoustic panels help reflect natural light from the clearstory windows deep into the classroom space.

Active systems

After a building’s heating and cooling loads have been minimized through passive strategies, it is then time to look at active strategies to further minimize energy consumption. One of the best examples of an active integrated strategy is a radiantly conditioned slab. The radiant slab combines the architectural and structural elements of a building’s floor with the mechanically engineered HVAC system. At HRMS, heated or chilled water from the geothermal water-to-water heat pumps is circulated through tubing embedded in the concrete slab. The thermal mass of concrete in the slab helps to level out the peaks and valleys typically seen in a building’s loads while the water circulating through the tubing efficiently delivers or absorbs heat as needed. Care must be taken in controlling a radiant slab as more time is required to bring it up to temperature or cool it down depending on the outside air temperature and internal load conditions.

When possible, it is advantageous to design an integrated ventilation system. On the HRMS project, ventilation air can be either passively brought in through the architectural elements or mechanically delivered to the space via rooftop heat recovery ventilators. The rooftop HVAC units are provided with a heat recovery wheel that transfers heat from warmer exhaust air into the colder outside air being delivered to the rooms. CO2 sensors located in the space regulate the amount of fresh air needed to be brought into the building, while a displacement air distribution strategy is used to further reduce the amount of energy used by fans to distribute air and increase ventilation effectiveness.

A building can provide ventilation either passively or actively, and lighting can be delivered in the same manner. To achieve net-zero energy, a building needs to have an optimized daylighting design to minimize the need for artificial lighting. At HRMS, energy-efficient indirect and direct/indirect lighting is used in classrooms, with daylight and occupancy sensors used to help ensure that artificial lighting is used only when needed.

After the energy end uses of HVAC and lighting are addressed, a building is then left with its process and plug loads, which encompass the energy used by computers, office equipment, cooking equipment, and elevators. To help reduce parasitic plug loads, HRMS has dual operation outlets with each receptacle containing one unswitched outlet and one switched outlet that shuts off when the building is not in use, as determined by an occupancy sensor. Other energy conservation measures for this end use are regenerative elevators, Energy Star-rated cooking equipment, and Energy Star-rated laptop computers, which use a third of the energy of a typical desktop computer.

Renewable options

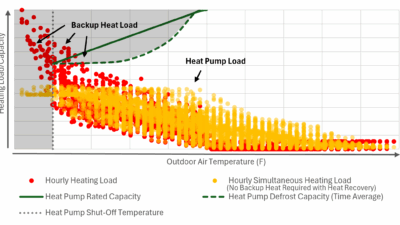

Renewable energy strategies are the next step in the integrated design process to net-zero energy after reducing the building’s energy consumption as much as possible through energy conservation measures. Energy simulation is invaluable at this point to give an estimate of how much annual energy needs to be offset by renewable energy strategies. HRMS had an EUI of 28 kBtu/sq ft/year after all of the energy conservation measures had been applied, which was 57% below a comparable ASHRAE Standard 90.1-2004 baseline building.

The first renewable strategy applied at HRMS was a transpired solar collector, which is a first stage to preheat ventilation air in the winter. The collector is constructed of an angled plenum on the roof with a black perforated panel facing south. This panel serves to heat up the plenum and thus preheat the incoming air. The largest renewable energy strategy at HRMS was a photovoltaic (PV) array. A 35 kW PV array was located on all of the south-facing roof area available. With the building’s area constraints, panel efficiency per square feet proved more important than cost per kWh. When applied, these renewable energy strategies resulted in a net simulated energy production of 0.3 kBtu/sq ft/year for the project.

Measurement and verification

The final step in the integrated design process to achieve net-zero energy is to verify the design intent has been met through commissioning and to measure the production and consumption of energy for comparison to the energy model simulation. The commissioning team acts as the owner’s representative, reviewing and observing the building’s system design and operation, verifying that they meet the owner’s operational requirements and the design team’s expectations.

It is crucial to properly meter and submeter a NZEB to potentially troubleshoot any discrepancies from the simulated building. The HRMS building was designed with two separate submeters on the building usage side:

- Mechanical and plumbing loads (ground source heat pumps, circulation pumps, heat recovery ventilators)

- Lighting and receptacle loads.

Along with the building submeters, there were also four separate submeters installed on the PV arrays to measure the energy production side. A year after the HRMS building was completed and occupied, a post-occupancy evaluation (POE) was performed by the architecture and engineering team to complete the M&V plan as submitted with LEED documentation. This POE was conducted using an occupant survey conducted by Opsis Architecture, analysis of metered energy and water use and recalibration of the design energy model by Interface Engineering, and faculty and facilities staff interviews conducted by both firms.

The HRMS building achieved net-zero energy through the year analyzed, although it accomplished it in a manner that didn’t align with the modeled results. In general, the model over-predicted the plug load/receptacle energy usage of the building while under-predicting the amount of heating energy needed in the building. On the energy production side, the photovoltaic array generated 16% more energy than predicted, which indicated a higher actual solar income than the weather file predicted in the original renewable energy calculation.

Overall, the integrated design process is essential to the success of any project that is targeting net-zero energy. The architecture and engineering team must work closely together through the design phase to incorporate both site and building strategies, which help push down the base energy consumption. Incremental first cost for energy conservation measures can be minimized by using integrated designs such as radiantly conditioned slabs, hybrid ventilation, and a daylighting system. Once the base building consumption has been pushed down as much as possible, renewable systems can be designed using wind, solar, water, or other naturally driven energy sources to offset the remaining energy.

It is highly recommended that the building be fully commissioned during the design and construction process to ensure that the systems are installed and operating to meet expectations. Last, it is critical to measure the performance of the energy consuming and producing elements of the building to verify that simulated targets are being met. The HRMS project used this integrated design process and it resulted in a successful NZEB.

Andrew Craig is an associate/senior mechanical engineer at Interface Engineering. As a specialist in energy and computational fluid dynamics simulation as well as mechanical systems design, Craig’s integrated approach to building system design has helped more than 30 projects become U.S. Green Building Council LEED certified, with several projects designed to achieve net-zero energy or Living Building targets.