Plumbing and mechanical engineers are frequently being tasked with doing everything they can to conserve water in commercial buildings.

Learning Objectives

- Outline the codes and standards that govern water use in nonresidential buildings, and understand how water use potentially differs between building typologies.

- Appraise the current water-management options, such as using greywater and rainwater, and look at less traditional management options, such as wastewater and condensate reuse.

A large portion of the U.S. West Coast has been experiencing a drought for a number of years now. California, in particular, is experiencing a “D4 Exceptional Drought” (the highest drought-intensity rating on the United States Drought Monitor) and the worst in the state’s history, which has led to mandatory water restrictions. Other parts of the country also are experiencing moderate drought or abnormally dry conditions.

These conditions place enormous pressure on potable-water storage and water supply networks. This not only creates water-supply uncertainties, but also brings about a realization in the broader community that water is an extremely valuable and finite resource that should not be taken for granted.

According to the U.S. Geological Survey Circular 1405, Estimated Use of Water in the United States in 2010, the total water withdrawals for public supply was 42,000 million gpd (nearly 14% of the total freshwater withdrawals). The majority of the remaining water withdrawals are primarily for thermoelectric power (45%) and irrigation (33%).

This article relates to tracking and conserving water in a range of commercial buildings including office buildings, retail developments, public and government buildings, educational and research institutions, health facilities and hospitals, and hotels and resorts. The breakdown of water use across these building types varies considerably (refer to U.S. Environmental Protection Agency’s WaterSense—Types of Facilities page); however, the three major uses of water are generally restrooms, HVAC (heating and cooling), and landscape irrigation. Kitchen, laundry, or washdown activities also can consume significant amounts of water for certain facilities. The commercial and institutional sector accounts for approximately 17% of withdrawals from public water supplies in the U.S., so significant savings can be made in this sector.

Low-flow fixtures

To achieve resilience in the face of water shortages, builders, engineers, and designers of new commercial buildings are looking to implement water-efficiency measures. These measures include using water-efficient fixtures and fittings—i.e., low-flow faucets and showerheads, low-flush toilets and urinals, dual-flush toilets, low-flow lavatory faucets—and adhering to maximum flow levels that have been mandated under the Energy Policy Act (EPAct) of 1992.

In the past, the difficulty with many low-flow fixtures was that without good fixture design, the performance was often compromised. For instance, low-flow toilets that fail to fully clear waste can result in double flushing, which potentially wastes more water than the higher-flow fixtures. To help protect against this, the U.S. Environmental Protection Agency (EPA) created the WaterSense Program in 2006, which is a national voluntary program that certifies products that use 20% less water than the national standards without sacrificing performance. Many states have individually established their own fixture-efficiency standards that, in most cases, match or exceed WaterSense standards.

In April 2015, the California Energy Commission approved standards that exceeded those of the WaterSense program in an effort to save more water and ease the effects of drought. California and a number of forward-thinking states are now leading the nation in water-efficiency standards. A comparison of the flow standards is listed in Error: Reference source not found.

Water-efficient fixtures are now common, relatively inexpensive, and one of the most cost-effective ways to reduce water use within new commercial buildings. However, caution should be applied when retrofitting older buildings with low-flow fixtures, as the older drainage pipe systems often have horizontal pipe gradients that are not designed to move solids with such low water flows, resulting in serious blockages.

No-flow or flushless urinals also can save considerable amounts of water. However, correct and continual maintenance is necessary to prevent odor and formation of solid precipitates, such as struvite or uric acid scale within the drainage pipe. The risk of formation of the latter can be alleviated through installation of higher-flow systems, such as lavatory sinks or showers upstream that drain into the same pipe. The flows from these other fixtures dilute the urine and help keep the pipe flushed. While the claims are “no-flow” or “waterless,” there is an amount of water required for cleaning and maintenance; although, admittedly, the volume required is greatly reduced as compared with its low-flush equivalents.

Vacuum toilets, such as those used in shipping and aircraft applications, also are being considered in some specific building developments as a water-saving measure. These systems use, on average, 0.26 gallons per flush (gpf) and approximately 2 watts per flush; they can be particularly useful in developments where gravity drainage is problematic (for example, developments over water, marinas, etc.). Continued operation can be challenging with these systems; there are noise issues and ongoing maintenance by specialty contractors is required to maintain efficient vacuum operation. The system results in a much more concentrated flow for disposal to the sewer drainage network, which may be a consideration for the controlling authority or service provider.

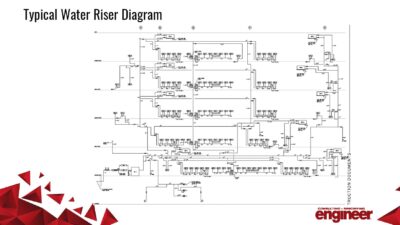

Error: Reference source not found shows an example of a typical office building. Potential water savings have been modeled in toilets and lavatories where low-flow units were installed. We have begun with an assumed population of 5,000 with a 50:50 mix of males to females. While the mandatory standards set by EPAct 1992/EPAct 2005 have reduced typical fixture flow rates from pre-1992 levels, the modeling shows that the savings that can be achieved through the tighter standards adopted in California are still quite considerable and, in this case, resulted in approximately 3 million gallons/year—or a water-usage reduction of 39%. Dual-flush toilets with an average water use of 1 gpf; (the average of one 1.6-gpf flush and three 0.8-gpf flushes) offer even greater savings.

Metering for water management, leak detection

Another simple and often underrated method to achieve water savings is through metering (see “Case study: Royal Society for Prevention of Cruelty to Animals” on page xx). A well-designed metering system can perform a number of highly valuable functions including assessment of water use across functional areas or zones and identification of high-water-use appliances or activities. It also can assist with the early detection of leaks.

Detailed knowledge of water used for various functions of the building allows water-management schemes to be developed that can identify areas of significant water usage and enable development of strategies targeted to achieve greater reductions in water use. The installation of meters alone does not save water and requires the appropriate infrastructure to provide monitoring, analysis, and reporting of water use and identification of unusual water use. Most building management systems (BMS) have become quite sophisticated in how they can process and report on acquired data. Once baselines are established, the BMS allows water-use setpoints and alarms that can be triggered to alert building managers of unusual events or abnormal operation.

One meter installed on the incoming water supply (usually for billing purposes) gives very limited information with regard to water use throughout the building. While leaks and inefficient water use may be detected, a large amount of investigation is then required to locate them. Currently, there are no requirements for submetering of water use within commercial buildings within the Uniform Plumbing Code (UPC) or the International Plumbing Code (IPC), which are the two major plumbing codes adopted across the U.S. Local and state codes and requirements may vary and should be consulted if in doubt.

The U.S. Green Building Council (USGBC) through LEED has implemented a building-level water-metering requirement as a prerequisite for achieving Water Efficiency (WE) credits. There is a separate water-metering credit that requires metering of at least two or more permanent water meters on water subsystems. The WE credits recognize the value of water metering in water management and the ability to identify opportunities for additional water savings through tracking of water consumption. The LEED reference guide lists the following water subsystems as applicable:

- Irrigation

- Indoor plumbing fixtures and fittings (>80% of water use)

- Domestic hot water (>80% domestic hot-water capacity)

- Boilers with projected water use of >100,000 gallons or more than 500,000 Btu/h

- Reclaimed water

- Other process water (including humidification systems, dishwashers, clothes washers, pools, etc.).

For health care projects to achieve LEED credits, additional requirements apply for water meters to be installed on a least five of the following subsystem water uses:

- Purified water systems

- Filter backwash water

- Water use in dietary departments

- Water use in laundry

- Water use in laboratories

- Water use in central sterile and processing departments

- Water use in physiotherapy and hydrotherapy and treatment areas

- Water use in surgical suites

- Closed-looped hydronic system make-up water

- Cold-water make-up for domestic hot-water systems.

While metering of cooling towers for HVAC is not included in the list, a separate credit with a more detailed analysis of cooling tower operation and performance is included to encourage water efficiency. This is based on minimizing water use while not exceeding maximum concentrations of salt and scale-forming contaminants. While the total water use in cooling towers depends largely on local weather conditions and can be highly variable, monitoring the make-up water use in these cooling systems through metering can still be of significant value. Cooling towers can consume a large proportion of the overall water usage, and metering can assist in the immediate detection of operational issues.

In a recent case in Perth, Australia, where a flow meter was retrofitted to cooling tower water supply, the building owner was alerted to high water use and then was able to identify a faulty float valve that was allowing a continuous overflow to the sewer. Repair of this valve saved approximately 2.5 gpm of water from draining to the sewer. Had the valve not been repaired for more than a year, it would have cost the building owner over 1.3 million gallons of water.

Consideration should also be given to air-cooled equipment such as dry cooling towers, which use the ambient air temperature to provide cooling and also hybrid cooling towers that use air when the temperatures are low and water when temperatures are higher, thus reducing overall water usage for the same amount of heat rejection. The compromise on these systems is in energy use and initial capital cost.

Leaks can also be a major source of “water use.” Even small leaks will cause major water use as they usually occur over a full 24-hour period, which adds up over time. While some leaks are obvious and are easily detected through drips, wet patches on floor coverings or ceiling materials, and occurrence of damp areas, some leaks occur hidden from site and are not detected until a large amount of damage has already occurred.

In addition, some leaks—such as in tank-style toilets in which the water leaks through the flush valve into the toilet bowl—can go undetected for years, as these do not cause any damage but simply drain to the sewer. Leaks in toilet flush valves can be detected through a “ripple test” in which the water surface in the toilet bowl is observed for a short period of time without flushing. If a ripple on the water surface is observed, there is likely to be a leak. Another method for detecting leaks in toilets with a cistern involves the application of a few drops of colored dye in the cistern—if there is a leak, the dye will start to color the water in the bowl.

Metering of water flows also can help in the detection of hidden leaks. For example, if the meter indicates there is still a base flow when the building is empty and all the water-using appliances and equipment are turned off (water flow should be zero) then it means there is a leak somewhere. As an example, a minor tap leak can be in the order of 0.01 gpm, which is equivalent to approximately 5,250 gallons/year. In a poorly maintained commercial building, you may have 20 or more taps leaking at any one time, which can add up to more than 105,000 gallons/year.

In the future, it is more likely that water use may be monitored by sophisticated pattern recognition technology that is able to recognize individual water-use events, such as the flush of a toilet, among a background of other water uses. This technology is based on the premise that the pattern of water flow for the flush of a toilet is individual and differs from that of a lavatory faucet turning on to wash hands or the flow of water when showering or filling a washing machine or dishwasher etc.

In a recent study, an intelligent pattern recognition model was used to automate categorization of residential water end-use events. This study relied on the use of high-resolution water meters (0.0037 gallons per pulse) and 5-second data logging; the model was validated through the study of 50 independent combined events. More recently, a product has been developed that uses the sound patterns of running water with similar pattern recognition technology to monitor water use. While these systems are not currently used in the commercial-building sector and further research work is required, it is highly likely that this type of approach will be developed and applied to the more complicated water-use patterns that occur in commercial buildings, allowing a much greater degree of monitoring and control.

Another inexpensive method to improve water efficiency is through end-user education. Simple techniques that alert staff and visitors to the efforts being applied in water efficiency can lead to significant behavioral change. Simple signage prompting users to check that taps are properly turned off and simple clear mechanisms to report leaks promptly to the maintenance department (with clear contact details) and other similar initiatives can result in substantial water savings.

In one example, an 8-story office building with a dishwasher located in a kitchen on each floor was alerted that dishwashers were being operated every day regardless of whether they were full of dirty dishes. Some simple user education and signage asking staff to only run the dishwasher when full reduced the usage to every second day, resulting in annual water savings of 100,000 gallons.

Water reuse

Another approach to further increase the resilience of a building design with regard to water use is to find other sources of water to supply the water demands. The aim is to provide water sources that are less reliant on weather and rainfall events and, therefore, more likely to be available during times of water shortage.

The most efficient way of approaching this is to match the quality, quantity, and timing of the water supply to water demands. Initially, an assessment of water demands should be performed to identify the quality and quantity of water required. The two main sets of quality parameters used to assess water quality are based on chemical properties such as pH, hardness, total dissolved salts, total suspended solids, and the presence of pathogens, such as bacteria and viruses. Each water source needs to be assessed in terms of risk for the required end use.

In some cases, the water needs to be potable-quality drinking water, such as water for human consumption and food preparation, water used for washing hands, showers, and where close and intimate contact with water is required. Other uses in commercial buildings are further removed from human contact and may be supplied nonpotable water such as irrigation, toilet flushing, cooling towers, boiler supply, and others. In each case, an assessment of the risks in terms of the chemical quality of the water and the likely presence of pathogens should be performed to ensure that appropriate treatment is performed prior to reuse.

The timing and quantities of water also should be matched where possible to ensure an efficient system. This is not to suggest that the quantities need to be exactly matched. Timing refers to the availability of the water, as some sources of water may vary seasonally or for other reasons and some demands also vary on a seasonal basis.

For example, consider the mismatch between high winter rainfall and summer irrigation demands. Irrigation demands are most-often highest during the hotter months. Yet, in many climates, there is significantly more rainfall in winter and spring than in summer. Attempting to provide rainwater (rainfall collected from roofs) in winter for irrigation in summer is highly inefficient, as the collection tank would need to be extremely large to maximize the winter-rainfall collection before it is supplied as irrigation in summer.

On the other hand, in climates with a higher summer rainfall, collecting rainwater to provide irrigation over summer is far more efficient; the tank is likely to be drawn down through irrigation between rainfall events, thereby maximizing capture, resulting in a much smaller tank size. This also applies to rainwater collection for cooling tower water supply demands, which are also much higher during the hotter months.

Other alternate sources of water may include site-collected stormwater, groundwater, and other relatively clean sources of wastewater that would require relatively little in the way of treatment, such as reverse osmosis reject and HVAC condensate, moving through to more contaminated water that would require significant treatment, such as recycling wastewater (greywater and blackwater) or harvesting municipal stormwater. Another source of nonpotable water in some areas is reclaimed water from the local water-treatment provider.

The amount of treatment required will depend on the contamination level of the water source, the quality requirements of the water demand, and the likelihood of direct human contact. For instance, site-collected stormwater delivered to a garden by subsurface drip irrigation may only require simple filtration to remove particles that may block the irrigation drippers. On the other hand, harvested municipal stormwater for use in cooling towers may require a much higher level of treatment including microfiltration and disinfection to remove pathogens.

Reuse also requires the installation of dual pipework either to separate wastewater streams, such as where greywater alone is being treated and recycled, or to provide separate supply lines so reuse water can be used for other purposes, such as toilet flushing. This duplication of infrastructure and provision of treatment systems can be costly, so the benefits of water-reuse schemes need to be carefully considered. They are generally more likely to be implemented where cost is not the only factor, keeping in mind that the true cost of water is only realized when it is not available.

Also, smart building design where restrooms on each floor are located above each other, thus reducing the level of duplication of pipework, can also reduce costs. A double use of space and resources, as used in the approach at the Peter Doherty Institute, is yet another approach to reduce costs. In this example, a landscaped area on the rooftop was used as a treatment zone. The cost of the greywater treatment system was offset by an amount allocated to provide a lush landscaped area outside the boardroom.

The two major plumbing codes in use in the U.S. are UPC and IPC. These codes cover aspects of alternate water sources and nonpotable applications including greywater reuse and rainwater catchment systems. Many states and local jurisdictions have adopted these codes directly or adjusted them to create their own codes, which in many cases are stricter than the originals. As such, for each project or building design where reuse is being considered, the authority having jurisdiction (AHJ) must be consulted with regard to the relevant codes and standards.

NSF International has also developed a standard/certification (NSF/ANSI Standard 350 and 350-1) for onsite water-reuse systems, and it is now a requirement of both the UPC and the IPC along with the International Residential Code and the International Green Construction Code that water-reuse systems supplying reuse water for toilet and urinal flushing (and in some codes irrigation) comply with this standard. This standard establishes the requirements for onsite reuse systems in terms of material, design, construction, and performance including the water-quality requirements. It requires a 26-week testing period with regular sampling and analysis in which to assess the reliability of water quality produced from the treatment system. The EPA also has guidelines (EPA/600/R-12/618) that cover many aspects of water treatment and reuse including water-quality requirements for various end uses.

As previously noted, commercial buildings come in various shapes and sizes and are used for a wide variety of purposes. While a number of approaches, including water-efficient fixtures and fittings and metering, can successfully be applied to all building types, to obtain further water savings requires assessment of each building on its merits.

Peter Harbour is a senior scientist at CJ Arms and Associates.

Robyn Overall is water sustainability scientist at CJ Arms and Associates.