High-rise buildings aren’t just big—for engineers, they present big challenges. HVAC systems and indoor air quality must meet exacting standards

Participants:

Jason Heffelmire, PE Gulf Coast operations director, TLC Engineering for Architecture, Tampa, Fla.

Mehdi Jalayerian, Executive vice president, Environmental Systems Design, Chicago, Ill.

Jim Quiter, PE, FSFPE, LEED AP, Principal, Arup, San Francisco, Calif.

CSE: What unique HVAC requirements do tall/super-high-rise structures have that you wouldn’t encounter on other structures?

Jalayerian: Super-tall developments offer energy reduction opportunities for HVAC systems associated with air conditioning zones located in higher elevations because higher altitudes offer cooler and less humid outdoor environments. Take Kingdom Tower, for example: The fresh air cooling energy requirement is 40% lower for the topmost air conditioning zone than the zone at grade level. Similarly, the heat gain from outdoor temperatures is 30% lower for the topmost spaces compared to those at the lowest portion of the tower.

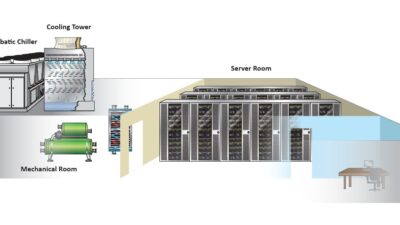

Heffelmire: Locating and rigging large equipment can be the biggest problem in high-rise buildings. For example, rigging a chiller in place on the 30th floor is extremely difficult but not impossible.

CSE: What changes in fans, variable frequency drives (VFDs), and other related equipment have you experienced?

Heffelmire: It seems that most pieces of equipment today are equipped with VFDs as the standard as the cost of these devices has come down substantially and more and more manufacturers are producing them. Years ago a VFD was the size of a dog house and was very expensive. Not so today. Fans (and their cousins, the pumps) have become more efficient but mostly by closer machining of certain parts. For example, you can hear a pump impeller scratch its casing upon start-up until it wears a little and fits tighter. Pump casings are pretty much still cast using the same molds used 50 years ago. The cost of bronze has risen, so some manufacturers are experimenting with stainless steel impellers instead of the heavier cast bronze.

CSE: What indoor air quality (IAQ) challenges have you recently overcome? Describe the project, and how you solved the problem.

Heffelmire: We design our projects very carefully to avoid IAQ problems. In a certain case on one of our projects, radon gas was discovered on the upper floors, a near impossibility. We traced it to a batch of bad gravel that came from a rock quarry in Virginia found loaded with radon. The radon found its way into the building’s block walls via the gravel. We added permanent outdoor ventilation air systems to the affected areas.

Jalayerian: The height of the building and the building design are two factors that influence the quantity of uncontrolled ventilation in a building. Vertical zoning of the air systems and building risers, introduction of air locks at the main lobbies and sky lobbies, and maintaining two air separation barriers between the building shafts and the exterior on typical floors provide a design approach with the highest degree of air infiltration control.

CSE: In your experience, have alternative HVAC systems become more relevant? This may include displacement ventilation, chilled beams, etc.

Heffelmire: Alternate HVAC systems like displacement ventilation and chilled beams are relevant for certain projects. Alternate HVAC systems always creep up, and many are just a re-packaging of an existing design. We used a variation of chilled beams in the 1960s where chilled water piping was imbedded in ceiling tiles and was a part of the ceiling system. Displacement ventilation systems are pretty innovative, but I personally prefer the simpler tried-and-true systems and make them as efficient as the hybrids we see today. In Florida, building owners receive generous incentive payments from the utility companies to make ice during off-peak hours and melt the ice during on-peak hours. This competes against a lot of the alternate HVAC systems on the market.

CSE: What unique dedicated outdoor air system (DOAS) projects have you encountered in these buildings?

Heffelmire: In Florida, because of our semi-tropical climate, almost all of our HVAC system designs use dedicated outside air pre-conditioning systems. Unlike northern states, cooling is always required year-round in Florida and humidity is always one of our biggest concerns. DOAS are more the norm than the exception. Because our building sizes lend themselves to the use of more direct expansion (DX) equipment than chilled water equipment, we have had to push existing DX technology to its limits.