Codes and standards dictate the design of HVAC systems; however, there are ways to improve the design of nonresidential buildings to achieve maximum energy efficiency.

Learning Objectives

- Examine owner and local codes for cooling system designs.

- Define HVAC codes and standards.

- Understand cooling systems to maximum energy efficiency.

Data from the 2012 Commercial Buildings Energy Consumption Survey (CBECS) shows that the United States consumes 6,963 trillion Btu of energy generated for commercial buildings. Figure 1 shows that 44% of commercial building energy use is for HVAC and refrigeration. National survey data shows approximately 50% of the HVAC energy is used for cooling, ventilation, and refrigeration purposes.

Efforts to reduce energy use led to the development of energy codes and standards to establish minimum efficiency requirements for new-building construction, building additions, and renovations. Providing comfort cooling and energy efficiency in nonresidential buildings is an ongoing task for engineers and designers as they increasingly have to focus on energy-efficient building codes and high-performance buildings. A building’s energy impact is determined by initial design decisions, operations, and the owner’s project budget. Energy codes and standards present designers with guidelines to enforce minimal energy savings through efficient design and implementing various equipment technologies.

Adopting codes and standards for energy efficiency

Designers in the HVAC industry must be familiar with codes and standards. Standards define the industry’s agreed-upon minimum technical requirements, procedures, guidelines, and instructions for engineers, designers, or manufacturers. They also establish the industry’s minimum standard of care. Standards in the United States are mostly voluntary consensus standards, which means they are regularly maintained and are developed through a consensus process. Examples of industry organizations that develop voluntary consensus standards are ASHRAE, Sheet Metal and Air Conditioning Contractors’ National Association (SMACNA), NFPA, and IEEE. These standards may or may not be written in enforceable language.

In contrast, a code is a standard that has been enacted into law by an authority having jurisdiction (AHJ) such that a designer is legally required to comply with that standard. The code may also include references to additional standards that can also be enforced. This procedure is called, “incorporation by reference.” An AHJ may amend the standard to incorporate or remove requirements, such as adding figures, charts, or tables, or amend the standard’s language, such as replacing the word “should” with “shall.”

In the U.S., the Department of Energy (DOE) is required by the Energy Conservation and Production Act to support, evaluate, and participate in energy code development as managed by ASHRAE and the International Code Council (ICC). DOE activities include evaluating energy and cost benefits associated with changes to ASHRAE Standard 90.1: Energy Standard for Buildings Except Low-Rise Residential Buildings and International Energy Conservation Code (IECC). DOE evaluates ASHRAE Standard 90.1 as the reference standard for commercial-building energy efficiency, and IECC as the reference standard for residential-building energy efficiency.

IECC and ASHRAE Standard 90.1 address building systems such as building envelope, lighting (exterior and interior), minimum HVAC equipment efficiency, HVAC systems, service water heating, and system controls. The standards also set the minimum energy efficiency and system design requirements. Both references have adopted code language to increase state adoption and improve enforceability.

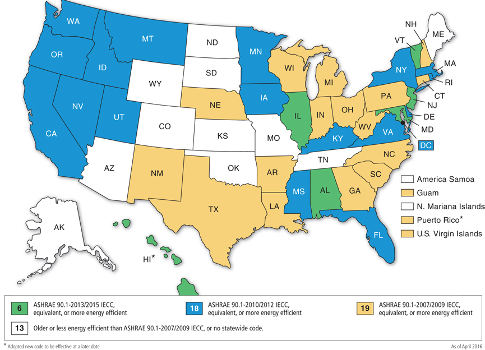

The U.S. does not have a national energy code or standard, even though the federal government supports the development of energy codes and standards. Because there is no national energy code, energy codes and standards are adopted at the state and local jurisdiction levels. The path that energy codes and standards take for adoption varies by locality. In general, energy code adoption is initiated when the DOE issues a positive determination based on the most recent version of ASHRAE Standard 90.1. The publication of a positive review sets in motion statuary requirements directing states and local authorities to certify they reviewed their building codes. All necessary updates are completed to meet or exceed the current edition of ASHRAE Standard 90.1. Many states also have their own code-update cycles that occur independently of ASHRAE, DOE, and IECC updates.

Each new edition of ASHRAE Standard 90.1 requires the DOE to issue a determination on whether the new edition will improve energy efficiency in commercial buildings over the existing edition. On Sept. 26, 2014, the DOE released a final determination that ASHRAE Standard 90.1-2013 would achieve 8.7% energy savings, 8.5% source-energy savings, and 7.6% site-energy savings above buildings designed under ASHRAE Standard 90.1-2010. Each state has 2 years to adopt ASHRAE Standard 90.1-2013 or update its existing commercial building codes and standards. With the 2014 determination, states will have until Sept. 26, 2016, to file compliance certifications with the DOE or request an extension.

Figure 2 shows the status of state energy code adoption as of April 2016. The codes, standards, and editions in force vary. Many states have adopted the IECC commercial code, which allows for an alternate compliance path through ASHRAE Standard 90.1. In jurisdictions that allow either compliance path, the designer must choose either IECC or ASHRAE Standard 90.1 as the design energy code and must complete the entire design using the chosen code. Designers are encouraged to consult with their local permitting agency and the AHJ to determine energy code requirements for states without an energy code.

Table 1 provides a summary of the HVAC cooling system energy and efficiency requirements according to the IECC and ASHRAE Standard 90.1. Corresponding equivalent code requirements between IECC and ASHRAE Standard 90.1 have been listed adjacent to each other where applicable. The IECC and ASHRAE have worked together over the years to make the two codes’ language and requirements documents similar, if not identical. However, some differences do exist between the two documents; most notably, regarding allowable exemptions to particular code provisions.

Compliance with codes and standards

In addition to the previously mentioned codes and standards, the following resources may provide additional guidance and recommendations for high-performance building system design. ASHRAE Standard 189.1 Standard for the Design of High-Performance Green Buildings “provides total building sustainability guidance for designing, building, and operating high-performance green buildings.” This standard may be applied to new construction, additions, and renovations to buildings. If ASHRAE Standard 189.1 is used for the design effort, the minimum system design requirements and equipment-efficiency requirements presented in that standard supersede the requirements presented in ASHRAE Standard 90.1. For example, ASHRAE Standard 90.1 requires demand-control ventilation (DCV) for high-occupancy areas served by systems with one or more of the following features: air-side economizer, automatic modulating outdoor air (OA) damper, or outdoor airflow greater than 3,000 cfm. ASHRAE Standard 189.1 revises the DCV requirement to include systems with an outdoor airflow greater than 1,000 cfm, thereby increasing the potential for energy-saving opportunities. Designers may find the ASHRAE Standard 189.1 User’s Manual helpful because it provides explanatory material that further elaborate on the requirements and intent of the ASHRAE Standard 189.1.

ASHRAE’s Advanced Energy Design Guides (AEDG) series also provides design and energy efficiency recommendations for various building types based on improvements to ASHRAE Standard 90.1 requirements. While the AEDG series was developed based on previous versions of ASHRAE Standard 90.1, the recommendations can still be applied to buildings designed to ASHRAE 90.1-2013 for possible energy savings. These guides provide recommendations on building envelope, fenestration, lighting systems, HVAC systems, service water heating, and plug/process loads arranged by climate zone. Even though the AEDGs are centered on new construction, the recommendations can be applied to renovations. While many of the AEDG recommendations are simply selecting between systems, the owner should be brought into the design process to ensure that the project goals are being met and the maintenance staff has the expertise to service the systems.

Establish project goals for energy efficiency

The design and use of high-performance HVAC equipment can result in significant energy and cost savings. Each design discipline has specific design requirements that must be met to comply with code. Each design discipline may also be presented with various opportunities for energy savings throughout the design phase. It should be noted and understood that energy savings in one discipline may enhance or detract savings and opportunities in another. This interaction applies not only to HVAC systems, but also to the envelope, lighting system, and, if under the control of the design team, the selection of office equipment. For the above reasons, design-team members must effectively communicate their design intent and required coordination items throughout the design process.

The first step in designing any efficient, effective HVAC system is to decide on energy goals early in the design process. Whether the project is new construction or a renovation, a thorough understanding of the owner’s project requirements and budgetary constraints is critical. This is often accomplished through a “basis of design” document that clearly communicates the design team’s understanding of the owner’s requirements, project goals for energy efficiency, and goals to achieve or exceed the minimum code requirements per the owner’s directives. These initial decisions will direct the selection of HVAC systems and equipment. A building that meets minimum energy code requirements will have a different HVAC system strategy and components than a building that achieves 30% energy savings beyond code minimum. In addition, highly efficient designs using high-performance HVAC systems most often require added effort and collaboration from all design-team members as compared with conventional designs.

HVAC cooling loads and equipment selection

For any new-construction or renovation project, a comprehensive knowledge of the building environment is critical. Many components affect HVAC loads and energy consumption including building envelope, fenestration (glazing and doors), lighting, plug loads, occupancy, and sequence of operations, to name a few. IECC and ASHRAE Standard 90.1 require building heating and cooling loads to be determined per ASHRAE Standard 183 or an “approved equivalent computational procedure.” Standard 183 provides methods and guidelines for developing building HVAC load calculations. Remember, heating- and cooling-load calculations are not the same as building energy modeling. Energy models analyze the proposed design energy requirements as the system operates over the entire year. Load calculations measure the energy that the HVAC system must add or remove from the zone to maintain the design conditions.

Accurate HVAC load calculations lead to properly sized equipment. Modern computer-aided load analysis tools allow the designer to reduce excess oversizing by removing many uncertainties, such as diversity, equipment loads, shading, and weather. Designers should consider equipment safety factors carefully, or not apply them at all, to avoid unnecessarily oversized equipment. For example, it is unreasonable to apply a safety factor to the calculated building load when the load is assumed to occur on the hottest weather design day with all zones at peak conditions, all lights on, all equipment operating, and each room is occupied by the maximum number of occupants allowed by fire code (higher occupancy than is reasonable). Oversized equipment may operate less efficiently and at a higher capital cost. This affects the owner’s project budget and operating expense. In addition, oversized cooling equipment may cycle excessively or not effectively dehumidify.

Both IECC and ASHRAE Standard 90.1 mandate minimum equipment-efficiency standards for all HVAC equipment. These minimum efficiencies represent the “worst legal” equipment allowed in the design. Designers should develop and maintain working relationships with manufacturer representatives as a means to use them as a resource during the design process. Reviewing the AEDG may provide an idea for enhanced cooling-equipment efficiencies based on the climate-specific tables for consideration. Request two or three equipment or system selections from the vendor and perform a simple payback analysis to justify any added equipment cost to the owner.

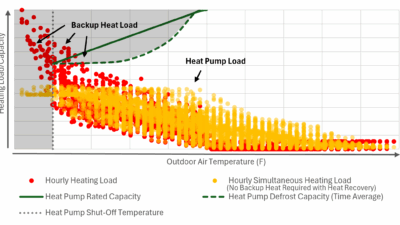

Designers should also consider the following when selecting cooling equipment. HVAC cooling systems are sized to meet design cooling conditions that meteorologically occur 1% to 2% (88 to 175 hours/year) of the year. This means that the systems are intentionally oversized at least 98% to 99% (8,585 to 8,672 hours/year) of the time. Consequently, cooling systems almost never operate at full design load. Typical systems operate at 50% or less of their rated maximum capacity. This makes part-load equipment performance a critical consideration for cooling equipment sizing. Consider selecting equipment and systems that can operate efficiently at part load, such as the following code-required systems:

- Variable air volume (VAV) fan systems with variable speed drive and static pressure reset controls

- Variable capacity pump systems with variable speed pump systems with pressure-reset controls

- Variable capacity chiller systems with variable speed compressors

- Variable capacity cooling tower systems with variable speed fans and reset controls

- Temperature-reset controls:

- Air-side supply-air-temperature reset

- Water-side systems for chilled-water-temperature reset and condenser-water-temperature reset.

An example of a supply-air-temperature reset schedule is shown in Figure 3. Air-side systems with cooling-only zones (electrical rooms, telecommunications closets, etc.) require consideration of these critical zones, as they may prevent the air handling unit (AHU) system from resetting the supply-air temperature (SAT). If critical zones are served by the AHU system, the system should be capable of meeting the zone loads at the reset SAT. Often, critical zones are served by dedicated systems separate from the central AHU systems. The above considerations would also apply to chilled-water-reset strategies.

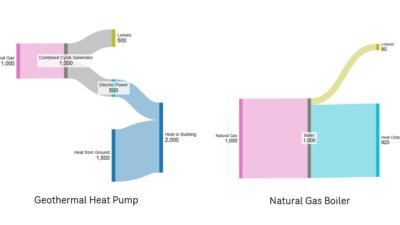

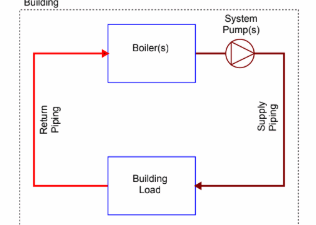

Cooling system design and controls

As previously mentioned, there are many ways to design a cooling system. For example, chilled-water systems can be designed for high-temperature differentials of 12 to 18° F delta T. Designing a chilled-water system to operate at higher temperature differentials has the potential to reduce the equipment cost and energy use as compared with the traditional 10° F delta T approach. This design strategy decreases the required water-flow rate and reduces pump energy. Higher differential temperatures have the added benefit of requiring small pipe sizes and reducing the pipe-installation cost.

Another approach would be to produce low-temperature water (38 to 40° F). Producing a lower leaving water temperature does use more chiller energy that may not be offset by gains in pumping and fan energy savings. However, low-temperature chilled-water systems are often used with thermal-storage systems. Chillers may be operated during off-peak electrical periods or when the equipment operates more efficiently to store energy (such as ice or water) for cooling the building during the day when electric rates are higher. Utilities may offer a better electric rate to “shift” the chiller load to off-peak hours, which may present the owner with savings even though the selected chiller is less efficient.

An additional energy-saving opportunity is to implement a chilled-water temperature reset schedule. The temperature can be reset based on OA temperature, zone-cooling demand, or both.

Comfort-cooling systems may require a water-side or air-side economizer to provide free cooling when outdoor conditions are able to fully meet or partially meet the cooling load. ASHRAE Standard 90.1 does not require air-side economizers in climate zones 1A or 1B because of limited operation hours in these hot and humid climates. All other climate zones require economizers on systems with a cooling capacity greater than or equal to 54,000 Btu/h. A fixed, dry-bulb temperature-type air-side economizer, schematically shown in Figure 4, enable point in a warm and humid climate would be 65° F. In cooler, dryer climates, the high-limit setpoint is higher. Economizer requirements for comfort cooling can be waived, provided the cooling system efficiency meets or exceeds the percent improvement listed in ASHRAE Standard 90.1, Table 6.5.1-3, for a particular climate zone.

Besides minimum system design requirements, IECC and ASHRAE Standard 90.1 establish minimum HVAC control required for systems. The following items are required to meet this minimum standard:

- Group zones into similar thermostatic control zones controlled by a single thermostat. For example, exterior zones and interior zones cannot be zoned together.

- Building automation systems (BAS) must employ time-of-day schedules and have night-setback/setup temperature setpoints. This is preferred over programmable thermostats because the occupants cannot override the zone setpoint.

- Optimal start controls for individual air systems must have a supply-air capacity greater than 10,000 cfm. A system with optimal start controls saves energy by reducing the HVAC system run time hours.

- Multiple-zone VAV systems must employ a supply-air-temperature reset schedule based on OA temperature, zone-cooling demand, or a combination.

- Systems with direct digital control of individual zone boxes must report to the central control panel and have a static pressure reset schedule based on the zone requiring the most pressure.

Throughout the years, many different HVAC systems and control strategies have been created to standardize control sequences and aid in the design process. ASHRAE developed a set of control sequences for commonly used HVAC systems. These sequences provide a good starting point for the designer who can expand the sequences to suit the particular HVAC system requirements, state codes and standards, and owner’s requirements.

Because control sequences are key in achieving energy management and savings, ASHRAE has recently created a committee tasked to develop and maintain the “best-of-class control sequences that will meet or exceed the requirements of ASHRAE Standards 55, 62.1, and 90.1.” The efforts of this committee resulted in the creation of Guideline 36. These high-performance, efficient sequences are meant to control air-side systems that use fully programmable, modern direct digital control (DDC) BAS, such as variable speed and capacity equipment. As of today, these sequences are under a public review (draft) period and have yet to be finalized. When formally published, these standardized sequences will provide the industry with premium building controls that will yield high-performance systems.

Cooling ventilation and energy-recovery systems

Dedicated outdoor air systems (DOAS) can reduce energy consumption by removing the ventilation OA conditioning and dehumidification load from the zone-cooling loads. A separate DOAS unit will heat, cool, and dehumidify the OA to deliver dry, neutral air to the space. This has the added effect of offsetting the space-latent load provided that the ventilation-air dewpoint temperature is sufficiently below the zone dewpoint temperature. DOAS configurations may include direct-exchange (DX) coils, chilled-water coils, indirect gas-fired heating, hot-water coils, steam coils, and an energy-recovery device. Dedicated OA systems can be used in conjunction with single-zone or multiple-zone systems. More than one strategy may be used to further reduce DOAS energy costs.

- Consider supplying cold OA rather than neutral-temperature air directly to the zone. This can reduce cooling energy and can partially meet the zone sensible-cooling load. The terminal HVAC equipment capacity must then be reduced to account for the cooling-load offset caused by the cold OA supply. Note that many design paths can be taken, and many other factors, such as space humidity, should also be considered during the design process.

- Integrate demand-control ventilation (DCV) with modulating dampers and airflow-measuring stations with the dedicated OA system. DCV can use a combination of space carbon dioxide (CO2) sensors in heavily occupied zones and occupancy sensors in normally unoccupied and limited-occupancy zones. ASHRAE Standard 62.1 outlines when a system must use DCV. The control sequence of operation can be complex, but a general guide is presented in ASHRAE Standard 62.1.

Exhaust-air energy recovery is used to precondition the OA stream by moving energy to and from the exhaust airstream. This can be achieved with sensible heat-exchange devices (sensible energy transfer only) or total energy-exchange devices (sensible and latent energy transfer). During cooling operation, the OA is pre-cooled and partially dehumidified. During heating operation, the OA is preheated and partially humidified. Commonly used air-side energy-recovery devices are run-around loops, plate heat exchangers, total energy wheels, and heat wheels. Table 6.5.6.1 provides exact conditions when an HVAC system requires energy recovery. The requirements are based on climate zone, percent OA, and design supply airflow. When an energy-recovery device is required, the system must have a minimum 50% effectiveness.

The exhaust and outdoor airflows should be balanced as close as possible to maximize energy transfer and to maintain building pressurization. Bypass dampers must be installed around the energy-recovery device when an HVAC system uses an air-side economizer. It is imperative to downsize the heating and cooling equipment based on the adjusted design loads with energy recovery. Right-sizing the heating and cooling equipment will have a cascading energy savings (such as reduced pumping power, downsized chillers, and boilers).

Maximizing HVAC cooling system designs for comfort cooling and energy savings requires a good understanding of owner and local code-related requirements; defined energy goals; complete interdisciplinary coordination; efficient and right-sized equipment selection; and multiple design iterations. With these steps and understandings, designers are better prepared to tackle many of the system design challenges encountered in comfort cooling.

Gayle Davis, PE, CGD, CxA is a project manager/mechanical engineer with Stanley Consultants. He has experience in project management, design and commissioning of mechanical systems for building services, central heating and cooling plants, and industrial facilities.