This first of this three-part series describes UV-C light and how it is applied as a clean-up tool in all types of air conditioning systems.

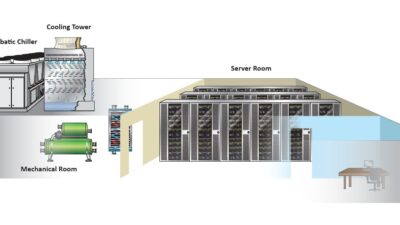

Light energy in the ultraviolet-C (UV-C) wavelength has been used extensively in HVAC equipment since the mid-1990s to improve indoor air quality (IAQ) by eliminating the buildup of biofilms and other organic contaminants on the surfaces of system components, including cooling coils, plenum interiors, drain pans, and air filters. UV-C works by disassociating elemental bonds, which in turn disinfects and disintegrates organic materials.

In new systems, such buildups are avoided by the continuous cleaning of equipment with UV-C. In retrofit applications, UV-C eradicates organic matter that has accumulated and grown over time, and then prevents it from returning.

Although UV-C is a relatively simple technology, many engineers, building owners, and other facility professionals are mystified about how UV-C works and how to apply it cost effectively. Mystification leads to mistrust.

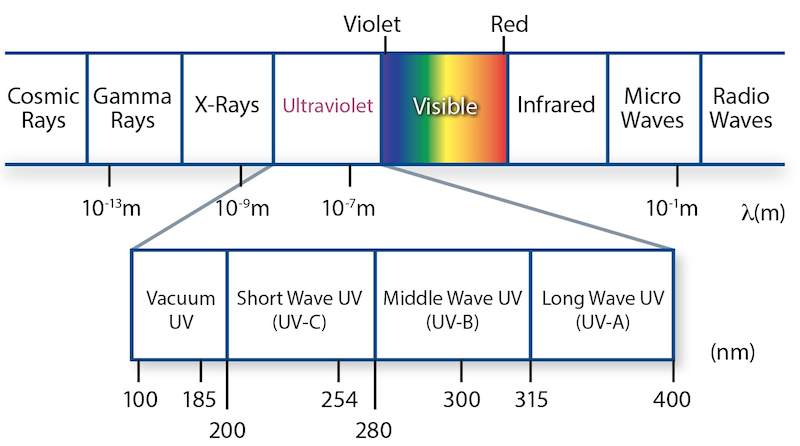

This three-part feature addresses the aspects of UV-C technology and the applications that seem the most awkward using ASHRAE guidelines found in Chapter 60: Ultraviolet Air and Surface Treatment in the 2011 ASHRAE Handbook – Applications. This first installment describes the nature of UV light, that is, electromagnetic radiation at a wavelength of 253.7 nanometers (nm) labeled “UV-C,” and how properties of UV-C light have been applied as a clean-up tool within all types of air conditioning systems.

The second part will explore how UV-C light is generated by lamps that are very similar to fluorescent lamps found in commercial ceiling light fixtures. The topics of lamp life and replacement schedules also are covered to set the stage for using UV-C lamps in HVAC systems. The final installment in the series will discuss how UV-C lamps are applied within HVAC systems to clean cooling coil surfaces, drain pans, air filters, and ducts for the purposes of attaining and maintaining “as-built” cooling capacity, airflow conditions, and IAQ.

UV light comprises a segment of the electromagnetic spectrum between 400 and 100 nm, corresponding to photon energies from 3 to 124 eV. The UV segment has four sections, labeled UV-A (400 to 315 nm), UV-B (315 to 280 nm), very high energy and destructive UV-C (280 to 200 nm), and vacuum UV.

We all are familiar with the deleterious effects of UV transmitted by sunlight in the UV-A and UV-B wavelengths, giving rise to UV inhibitors, or blocking agents, which are found in glasses and lotions. We are also familiar with products engineered to withstand the effects of UV radiation, such as plastics, paints, and rubbers. However, unlike UV-A and B, the UV-C wavelength has more than twice the electron volt energy (eV) as UV-A, and it is well absorbed (not reflected) by organic substances, adding to its destructiveness. Learn more about the electromagnetic spectrum in a video from NASA.

UV-C’s germicidal effects are well proven. It owes these effects to the biocidal features of ionizing radiation, that is, UV-C does far more damage to molecules in biological systems than can temperature alone. Sunburn, compared to the sensation of warmth, is one example of that damage. Sunburn is caused by sun striking living cells in the epidermis and killing them; the redness is the increased capillary action and blood flow enabling white blood cells to remove the dead cells.

Ionization drives UV-C’s power to alter chemical bonds. It carries enough energy to excite doubly bonded molecules into a permanent chemical rearrangement, causing lasting damage to DNA, ultimately killing the cell. Even a very brief exposure can render microbial replication impossible. After being killed, organic remnants are subject to photo-degradation (disintegration), a key feature of UV-C energy.

UV-C is absorbed by the ozone layer and much of the atmosphere, and does not make it to Earth’s surface; vacuum UV resides principally outside of the atmosphere.

Exposure and consequent dosage is the quantity of UV-C light absorbed over a specific period of time. A 2010 study commissioned by ASHRAE and the Air Conditioning, Heating, and Refrigeration Institute (AHRI) found that even the most sophisticated organic compounds suffer from exposure to small dosages of UV-C energy. Because UV-C lamp installations in HVAC applications operate 24/7, time is infinite, so surface materials are both disinfected and disintegrated. Once gone, they won’t re-form as long as the lamps are maintained.

Unlike manufactured compounds, the mostly simple organic debris as found on coil surfaces are fairly easy to degrade. And because aluminum is among the best inorganic reflectors of the UV-C wavelength, UV-C energy is easily directed deep into and throughout a cooling coil.

The next installment in this three-part series will set the stage for using UV-C lamps to disinfect HVAC system components.

Forrest Fencl is president of UV Resources. He is the writer or co-writer of 15 patents, is an ASHRAE Fellow, and formerly an ASHRAE Distinguished Lecturer. He has authored numerous papers and articles and several ASHRAE Handbook chapters related to ultraviolet air and surface treatment.