Complying with the latest NEC and OSHA requirements will improve equipment protection, electrical safety, and power reliability.

Learning objectives:

- Identify issues electrical engineers should identify to enhance worker safety.

- Interpret Short-circuit current rating (SCCR) requirements, codes, and standards.

- Apply fault current calculations.

Short-circuit current rating (SCCR) is the amount of available fault current that an electrical component or equipment can safely withstand, when properly applied. Adequate SCCR is imperative to support a safer workplace and protect equipment. Consequently, OSHA and NFPA 70: National Electrical Code (NEC) have specific SCCR requirements for equipment, such as industrial control panels, industrial machinery, general equipment, and HVAC equipment. Failure to provide equipment with adequate SCCR can have serious consequences including exposure to arc blast, flying debris, electric shock, burns, and others. A properly applied equipment SCCR is an important element in the safety of personnel and surrounding equipment.

Realizing properly applied equipment SCCR begins with a solid equipment SCCR strategy. There are several challenges that should be considered to achieve code compliance:

- Unknown available fault current levels at each circuit location. The NEC requires the maximum fault current to be marked at the service entrance, but downstream equipment are often ignored.

- Absence of equipment SCCR requirements on new-equipment specifications. Without clear insistence or guidance on equipment SCCR, this critical rating is often not communicated upfront during equipment design and installation. Once installed, it is often very difficult and costly to raise the equipment’s SCCR.

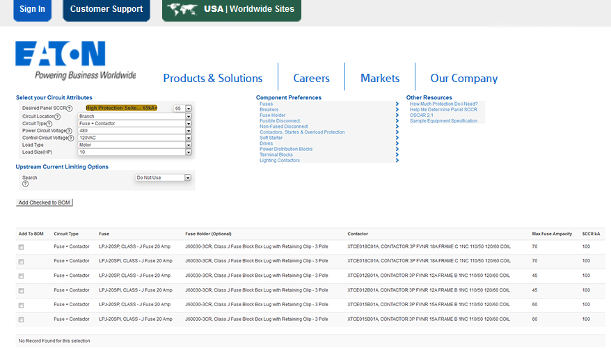

- Difficulty locating component SCCR for the devices used in industrial control panels. Industry surveys conducted by Eaton and a third party indicate that most equipment designers have some degree of difficultly locating component SCCRs for the devices they use in industrial control panels. Searching for this information can result in project delays. Engineers without access to comprehensive component SCCR information often make design decisions that result in specifying devices that are larger than needed, higher in material costs, and potentially require larger enclosures. Component SCCRs are found on the device labels or instruction sheets, but often the equipment designer doesn’t have these in hand when selecting a solution. Some component SCCRs are posted on UL’s SCCR webpage by manufacturers. However, this UL list is not exhaustive. Regardless, it is important that the correct component solutions be applied to efficiently achieve the desired equipment SCCR.

- Lack of knowledge, misinterpretation, or misapplication of the UL 508A standard for control panels. The NEC does not require industrial control panels to be listed. As such, industrial control panels could be manufactured by entities who are not familiar with determining the equipment SCCR of industrial control panels per UL 508A. Industry surveys also indicate that equipment designers have difficulty understanding or applying the UL 508A standard for their industrial control panels. This could result in insufficient protection against faults or an inefficient design. It is vital that panel manufacturers provide proper documentation, verifying that their equipment SCCR was properly determined in accordance with UL 508A Supplement SB or that the design was tested and certified by a third party.

- Electrical system changes that result in higher available fault current. A fault current level is influenced by many factors: Changes to the utility source, changes made within a building’s electrical distribution system, or relocation of equipment within the electrical system could raise or lower available fault current requirements. Some changes with positive benefits for electrical-distribution efficiency or electrical-supply capacity may inadvertently increase available fault current levels, which may in turn be larger than the SCCR of the equipment located downstream. Industrial facilities should consider an equipment SCCR plan that provides a protection level that takes into account future electrical system changes or equipment relocations that can increase faul

t current levels.

Develop an effective SCCR strategy

An effective SCCR strategy strives to achieve the necessary equipment SCCR with minimal costs, resources, and effort. Unfortunately, an approach that works for one industry or application may not work for others. Installation sites typically vary in terms of fault current depending on the location of the device in the facility’s electrical distribution system.

That said, there are a three basic concepts for developing an effective SCCR strategy:

- Determine the available fault current

- Define and document the minimum acceptable equipment SCCR requirement

- Require all equipment suppliers to provide an SCCR analysis for all equipment specified for a project.

The first step is understanding the available fault current level—the amount of current that would be present in the event of a short-circuit event. Determining the amount of available fault current depends on a variety of variables, including available fault current from the utility (typically, an unknown and subject to change), size of the upstream transformers, fault generation from motors, circuit impedances, voltage drop, short-circuit power factor, and more. The complexity and interaction of these variables can make an exact calculation difficult. That said, a conservative approach can be used to quickly and cost-effectively estimate fault current levels and the amount of SCCR protection required for a specific location.

A "worst-case" available fault current calculation assumes a worst-case condition and is intended to minimize the risk that the calculated available fault current level is too low. This equation assumes unlimited current from the utility. It is also commonly accepted to estimate the motor contribution by multiplying the total motor full load amps (FLA) by four.

Ifc = Isc trans + Isc motors

Where:

Ifc = "Worst-case" fault current

Isc trans = Fault current contribution from transformer

Isc motors = Fault current contribution from motors

UL 1561-listed transformers that are 25 kVA and larger have a ±10% impedance tolerance, which can affect fault current levels. Thus, a 0.9 factor is applied to the transformer’s impedance percentage (%). The fault current contribution of a 3-phase transformer (ISC trans) is calculated using the following equation:

Where kVA = Transformer size

V= Secondary voltage

%Z = Transformer percent impedance

Isc motors = Total motor FLA x 4

An alternative to calculating the available fault current is to use a Web-based application to calculate available fault current. Look for an application that considers transformer and motor contribution as well as conductor/bus impedance when determining a fault current level.

The second step is to determine the minimum acceptable equipment SCCR. There are several factors to consider regarding equipment SCCR:

- If the equipment is relocated to another location in the facility, then the equipment SCCR requirement should consider present and future needs.

- If conductors may later be replaced by busway or more efficient conductors, then the equipment SCCR requirement should consider the impact on fault current levels from these changes.

- If the upstream transformer is subject to replacement by a unit with higher efficiency or larger capacity, the future-state fault current level should be considered in the equipment SCCR requirements.

- If the potential for other changes that could impact available fault current exists, such as an increase in the number/size of motors, this too should be factored when setting the minimum equipment SCCR.

Finally, it is critical that all equipment suppliers provide an analysis of the control panel’s equipment SCCR determination. The surveys mentioned earlier also revealed that half of design engineers struggle with interpreting or applying the UL 508A standard regarding SCCR. It is not uncommon for current-limiting devices to be misapplied in the panel’s equipment SCCR determination. One mistake can mean the difference between achieving the required SCCR and only achieving the minimum 5 kA. An analysis detailing how the component SCCRs and interrupting ratings are applied in conjunction with current-limiting devices helps support and validate the panel’s claimed SCCR.

The approach and implementation costs of an effective SCCR strategy can vary; however, it is critical to meet evolving equipment-protection requirements. Complying with the latest OSHA and NEC requirements can help enhance personnel safety and system reliability while protecting equipment investments.

Additional information regarding SCCR ratings and requirements can be found on via NFPA, NFPA 70E, and Electrical Code Coalition websites.

Erik Barnes is OEM marketing manager at Eaton.