Best practices for designing an automatic sprinkler system that can be easily inspected, tested, and maintained.

Learning Objectives

- Learn about the codes and standards that fire protection engineers should reference when designing fire sprinkler systems.

- Understand that inspection, testing, and maintenance are key to compliant fire sprinkler systems.

A sprinkler system designed strictly in accordance with the requirements of NFPA 13: Standard for the Installation of Sprinkler Systems does not necessarily lend itself to a simple regimen of inspection, testing, and maintenance. A sprinkler system designer needs to understand the various post-installation inspection, testing, and maintenance procedures required by NFPA 25: Standard for the Inspection, Testing and Maintenance of Water-Based Fire Protection Systems to design a system that can be inspected, tested, and maintained efficiently.

NFPA 13 serves as the primary automatic fire sprinkler system design and installation standard in the U.S. It is also adopted and used for fire sprinkler system design in locations outside of the U.S. Once sprinkler systems are installed, the application of effective inspection, testing, and maintenance (ITM) is required to ensure system performance during a fire event. NFPA 25 is the established standard for sprinkler system ITM criteria. An NFPA 13-compliant sprinkler system will include the minimum system features required to complete NFPA 25 ITM activities. However, even an NFPA 13 code-compliant system does not automatically lend itself to applying the most efficient ITM.

Experience has shown that when sprinkler system design features result in additional difficulty or cost in completing ITM activities, building owners often choose to forgo portions of the required ITM procedures over time. Poor ITM practices increase the probability that the sprinkler system may not perform properly when needed. NFPA 25 ITM activities may be accomplished with greater ease and are, in turn, more likely to be completed over the sprinkler system’s lifetime when the system is designed to include features that increase the practicality of ITM. The following describes best practices that may be used to meet some of the NFPA 13 requirements while still facilitating the ITM activities described in NFPA 25.

Inspecting sprinkler system components

Sprinkler system components are required to be visually inspected at regular intervals. For example, NFPA 25 requires quarterly inspections of gauges, control valves, waterflow alarm devices, and supervisory devices. Gauges on dry and pre-action systems are further required to be inspected on a monthly basis. Gauges are inspected to ensure that they are free from physical damage and are displaying normal system pressures. Valves, waterflow devices, and supervisory devices are inspected to ensure that they are free of physical damage. In addition, valves are inspected to ensure that they are maintained in the appropriate orientation (open/closed). This inspection is of particular importance due to the fact that “normally open” valves placed in the closed position are known to serve as a leading cause of sprinkler system failure. According to NFPA’s June 2013 article, “U.S. Experience with Sprinklers,” 64% of sprinkler systems failed to operate during a fire scenario due to system valves being closed. Closed valves serve as a leading cause of sprinkler system failure.

All of the aforementioned components are generally located at the sprinkler system riser or at sprinkler system floor control assemblies. Given the frequency of these inspections, the sprinkler system designer can best serve the building owner by locating the risers and floor control assemblies where such devices can be easily viewed, preferably without the need for a ladder. The 2016 edition of NFPA 13 refers to this need in Section 8.1.2 by requiring that system valves and gauges be accessible for operation, testing, and maintenance. The Annex note for this section allows that valves do not have to be in an open or exposed location and may be located behind doors, removable panels, or in valve pits. Given these vague guidelines, one could argue that a valve located 20 ft above a finished floor can be reached by scissor lift and considered accessible.

Most sprinkler system designers and installers locate sprinkler system risers and trim at a height that can be easily reached and viewed for inspection and maintenance. However, in multifloor buildings, floor control assemblies tend to be located near ceiling level either inside a stairwell or outside of stairwells, or above suspended ceilings. To facilitate ease of maintenance and inspections, it is recommended that the system designer locate floor control assemblies inside stairwells rather than above suspended ceilings. Following this rule provides the advantage of easy visibility for inspection, testing, and maintenance and also makes the floor control valve considerably easier to locate in the event of a system accidental discharge. Additionally, it is recommended that the floor control assembly be located no higher than 7 ft above the stairwell landing, where the stairwell landing depth is of sufficient size to accommodate such equipment without impacting required egress width.

In addition to quarterly inspections, a number of components are required to be inspected annually including hangers and seismic bracing, sprinklers, pipe, fittings, spare sprinklers, system information signage, and fire department connections. The majority of these items are located as necessary to meet system design criteria including design density and spacing. The designer, therefore, has minimal control over location for ease of ITM.

Section 8.16.1.1.8 requires identification signs at every control valve to indicate valve function and what the valve controls. While not required by NFPA 13, it is also recommended that valve identification signs indicate whether a valve is intended to be normally open or normally closed. This is one of several sections requiring signage for identifying various components. These signs are vital for better serving building owners, maintenance staff, and responding fire department personnel who may not be fully familiar with the building layout and the details of the building design.

Testing sprinkler systems

NFPA 25 requires that a main drain test be completed on an annual/quarterly basis (depending upon system configuration) to determine if any degradation of the water supply has occurred. A portion of this test involves fully opening the main drain valve and allowing water to flow for a duration long enough to obtain a stabilized residual pressure before the valve is closed again. To facilitate this test, the 2016 edition of NFPA 13 Section 8.16.2.4.6.2 states that the main drain test connection “shall be installed that the valve can be opened wide for a sufficient time to assure a proper test without causing water damage.” If the final design of the main drain does not permit full flow for a long enough duration, sprinkler system service personnel may be forced to throttle the drain valve, close the drain valve prematurely, or not perform the test at all in an effort to prevent water damage. Ineffective main drain tests may allow a degraded water supply to go unnoticed.

One common method is to route the main drain discharge to the exterior of the building. Alternatively, practicality or local environmental laws may require that the main drain be discharged to the sanitary sewer. In both cases, a number of factors must be considered by the engineer to ensure that the main drain will be installed to allow for proper testing.

If the drain will discharge to the exterior of the building, the engineer should consider whether the discharge location will negatively impact property, vegetation, building use, etc. Is the discharge location sufficient to prevent water from flowing back into the building? Is the ground surface at the discharge location capable of resisting erosion due to water discharge? Could vegetation, vehicles, or other nearby objects be damaged by the discharge of water? Will the discharge of water outside during the winter months create a dangerous situation, such as an ice-covered building entrance? If discharging to an interior floor drain, it is important to ensure that the test can be completed without negatively impacting the building interior due to flooding or splashing. Can the floor drain handle the anticipated flow? Is the drain located near storage or electrical components? The engineer should estimate the expected waterflow from the main drain. This will depend on the water supply pressure and drain piping size and will drive the necessary size of the interior floor drain. If the drain cannot be sized to fully handle the anticipated flow, then consideration should be given to providing a contained space into which excess water can be permitted to accumulate.

Backflow preventers are required to be tested annually by forward-flowing water at a flow rate greater than or equal to the system demand. While this requirement has been included in NFPA 25 at least since the 1992 edition, NFPA 13 does not contain any specific direction to help the designer identify how to meet this requirement. For example, the U.S. Department of Defense Unified Facilities Criteria 3-600-01 Fire Protection Engineering for Facilities, with Change 1, November 2016 specifically requires that all new sprinkler systems be provided with a test header consisting of 2½-in. angle or globe valves, with at least one valve for every 250 gal per minute (gpm) of system demand. NFPA 20: Standard for the Installation of Stationary Pumps for Fire Protection also contains some guidance for providing waterflow test devices, such as test headers and closed test loops using flowmeters. Traditionally, sprinkler systems that do not require fire pumps have not been provided with a test header or a closed test loop even though these two methods provide the best means for accomplishing the yearly forward flow test. Without the provision of a test header or test loop, the best way to forward-flow test a backflow preventer is to reverse the fire department connection (FDC) check valve and allow water to flow out of the FDC. The amount of effort required to reverse the check valve and perform the test is likely to be a strong deterrent to performing this test. It is, therefore, recommended that sprinkler system designers include a test header in their design, sized to provide at least one 2½-in. valve per 250 gpm of system demand. The test header should be located on a building exterior wall or as a part of an exterior backflow preventer assembly in areas not subject to freezing. Given the large amount of water that can be discharged during a forward-flow test (approximately 200 gpm for a light hazard system; 350 gpm for an ordinary hazard group 1 system), the test header should be located so that a 50-ft hose can discharge water to a location that does not negatively impact nearby buildings or vegetation. A nearby storm drain may be ideal, if permitted. Where local environmental laws prohibit sprinkler system discharge to the exterior or to storm drains, it may be best to locate the test header near a roadway so that the hose can discharge to a truck-mounted portable tank.

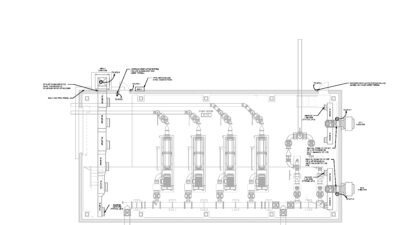

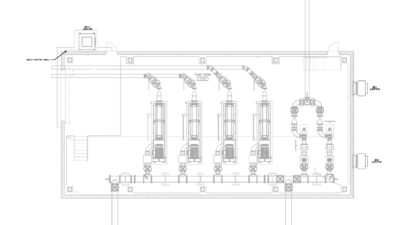

NFPA 25 requires pre-action and deluge valves to be trip tested. This test can be completed with a partially opened control valve annually and with a fully opened control valve every 3 years. In each case, water is admitted into an otherwise dry system. Pre-action systems are frequently installed in locations, such as data centers or refrigerated buildings, where the accidental release of water can result in especially costly damages. Annual trip testing introduces unwanted water into the dry portion of the system piping. Even when piping is properly sloped and provided with the proper drains, it is very difficult to remove all of the water from the system. Additionally, if the pre-action system is protecting a freezer, the water from the trip test may freeze in the piping prior to being drained. The remaining water in the pipe increases the system’s susceptibility to corrosion and damage due to freezing. For these reasons, a trip test that does not introduce water into the system piping is preferred. NFPA 13 allows for a second indicating control valve to be installed in the riser assembly above the pre-action or deluge valve to permit full function trip testing without flooding the system piping. The specifying engineer or consultant should consider including the second indicating valve in the design. Without this valve, it is likely that NFPA 25’s required trip testing would be considered impractical (e.g., systems protecting cold-storage warehouses) and may not be performed at all.

Maintenance for sprinkler systems

NFPA 25 states that, at a minimum, dry-pipe system auxiliary drains should be drained after each operation of the system and before the start of freezing weather conditions. It is vital that condensate be regularly drained from these auxiliary drains to prevent freeze failures of the dry-pipe system. If possible, the engineer should stress to the building owner the importance of regularly emptying these drains.

Dry-pipe sprinkler systems typically have a number of auxiliary drains. Building owners and maintenance personnel are not always aware of the location of every auxiliary drain. To facilitate the regular emptying of these drains, NFPA 13 requires a sign at the dry-pipe valve that indicates the number and location of each low-point drain. The standard requires that this sign be a permanently marked metal or rigid plastic sign. The engineer should pay close attention to ensure that the installing contractor adheres to this requirement. A laminated sheet of paper listing the drain locations, thumbtacked to the wall adjacent to the dry valve, is likely to become unreadable over time. Without this sign, a low-point drain may be overlooked. For example, a low-point drain located under the stair in a far corner of a large building can be easily forgotten by building maintenance staff or overlooked by a sprinkler system service company during a 1 a.m. emergency service call.

Proper documentation for sprinkler systems

Almost inevitably at some point in the lifetime of a sprinkler system, having access to the original contractor-prepared, as-built shop drawings and hydraulic calculations will be greatly beneficial. Many times, the original shop drawings and other documentation pertaining to the original system installation are lost shortly after construction is completed, or accurate as-built shop drawings are not provided. Without these documents, many situations, such as renovating an existing sprinkler system, evaluating an existing sprinkler system for protecting a new hazard, or investigating a recurring maintenance issue, will likely require the contractor or engineer to recreate at least some of the lost information. The investigation to recreate the missing as-built drawings will have an associated cost and may be destructive in nature. While NFPA 13 does not have a requirement for retaining working plans and calculations, the engineer may want to consider the use of a documentation cabinet similar to what is required by NFPA 72: National Fire Alarm and Signaling Code. This cabinet can be used to store as-built drawings, calculations, operations and maintenance manuals, and ITM records in a convenient waterproof location. Depending upon the type of cabinet specified, electronic files (i.e., CAD files of the system design and acceptance test documentation) may also be stored.

Inspection, testing, and maintenance activities are essential to prolonging the life of sprinkler systems and ensuring that sprinkler systems are able to operate as designed in the event of an emergency. An engineer can include a number of simple features in sprinkler system design to make ITM activities easier and less of a burden for the building owner and maintenance staff. These features include informative and durable signage, test-valve discharge locations that minimize their impact on the building and environment, system riser locations that afford visibility and easy access for ITM, and additional valves that reduce the amount of labor required for annual testing and allow for the isolation of maintenance activities. Providing a designated location for as-built document storage and ITM recordkeeping will help to reduce the amount of rework required when system modifications are necessary.

Andrew J. Taggart is a senior fire protection engineer at JENSEN HUGHES and has more than 9 years of experience in the design of fire suppression systems including experience as a fire protection consultant and a fire sprinkler contractor, during which he often assists building owners in solving ongoing sprinkler system maintenance issues.

Julie E. Buffam Brown is a senior fire protection engineer at JENSEN HUGHES. As a fire protection engineer and code consultant, she has performed numerous property condition assessments and has seen many instances where poor design can impact the frequency and quality of sprinkler system inspection, testing, and maintenance.