This laboratory was considered a mission critical facility, necessitating redundancy and resiliency for its power systems.

The engineering team was tasked with designing a state laboratory housing the state medical examiner, state police forensics labs and various chemical and biological testing labs including biosafety level 3 classified areas. While not requiring compliance with NFPA 70: National Electrical Code Article 708 Critical Operations Power Systems, this facility was considered mission critical due to multiple state-run services that were required to be available at all times. The publicly funded project was required to adhere to a strict construction budget, which necessitated careful design to achieve satisfactory power resiliency.

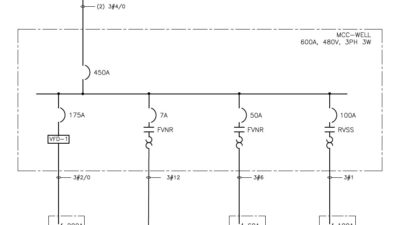

Normal power: As efficiency was needed both on space and budget, the facility was provided with exterior pad-mounted, solid dielectric, vacuum interrupter switchgear, which received two feeds from the campus’s main substation. This type of switchgear was chosen due to its low maintenance and robust construction. Each feed was independently routed underground and served from different substation transformers. Additionally, the campus received four independent primary feeds from the local utility provider set up in a primary selective configuration.

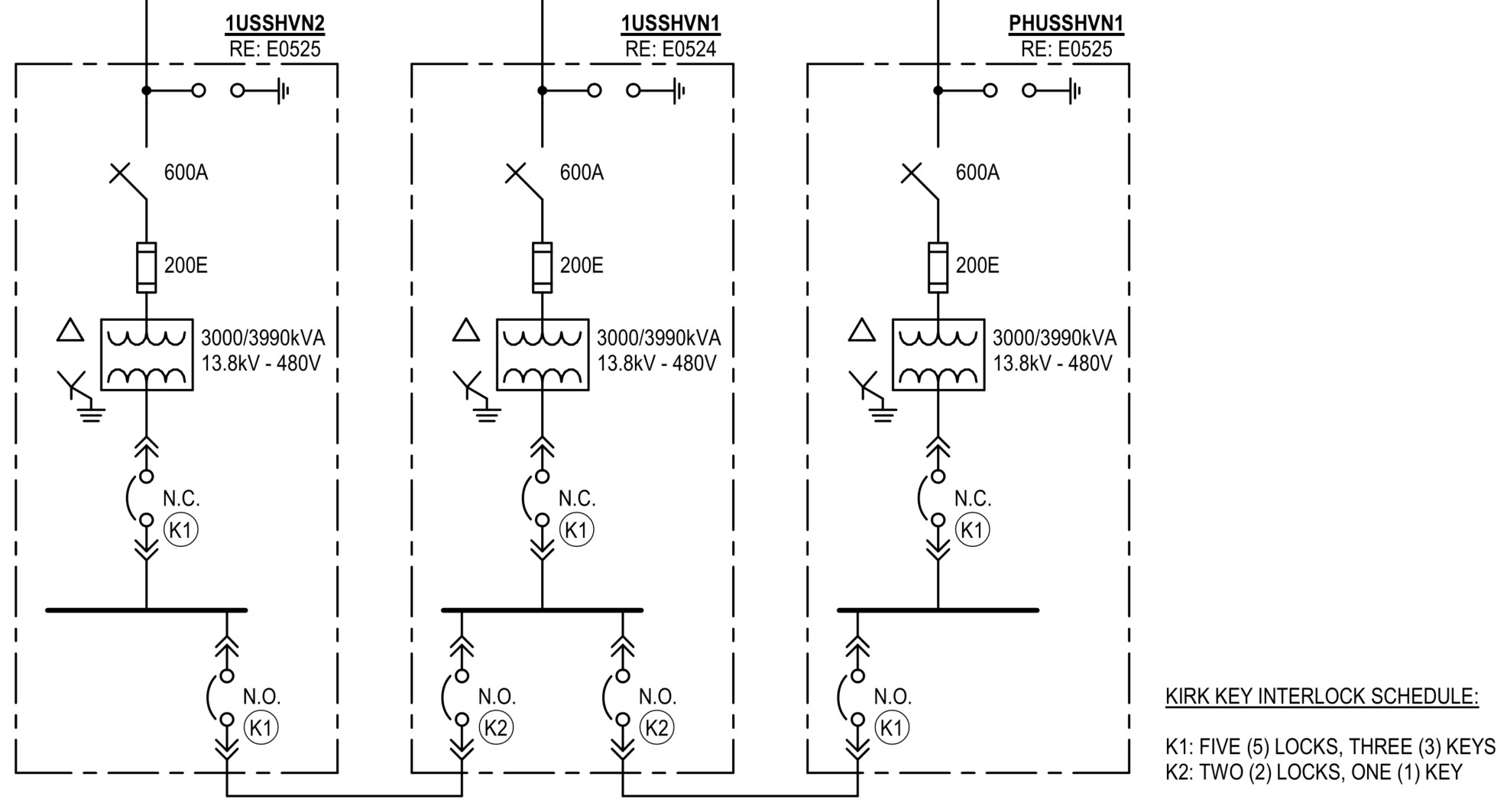

The pad-mounted switchgear provided service to three single-ended unit substations within the building. Double-ended substations could not be accommodated due to space limitations. To achieve partial transformer redundancy, the substation capacities were increased and secondary cross-ties were provided between the substations. Each cross-tie was sized to provide 66% capacity to the reliant substation and the main and tie breakers were interlocked with a simple kirk key scheme. This setup allowed for a single substation transformer outage without complete reliance on the generators for an extended period.

Standby power: The facility was provided with four 1,300-kilowatt natural gas generators to supply emergency and standby power. Natural gas was chosen due to its availability and ability to provide indefinite runtime. While authority having jurisdiction approval was needed for this arrangement, the project is in a nonseismic zone and the natural gas service provider are able to confirm reliability for the fuel source. The generators were paralleled together at interior paralleling switchgear; a tie breaker was not provided as all 10-second loads fit comfortably within the capacity of a single genset.

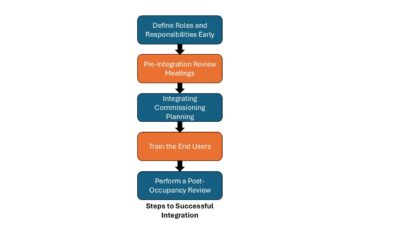

Downstream of the paralleling gear, transfer switches were carefully arranged to ensure that power sources were diversified for various systems. Critical equipment and mechanical systems such as chillers, cooling towers, boilers, pumps, laboratory exhaust fans, air handling units and autoclaves were split between transfer switches to allow a given piece of electrical equipment to be out of service without shutting down a complete system. Additionally, all transfer switches were bypass isolation type.

Finally, central uninterruptible power supply (UPS) power was needed for certain program elements. Four smaller (150 kilovolt ampere) UPSs were provided to diversify the source and each UPS was arranged with N+1 batteries, as well as an external bypass for interruption free maintenance.

While the overall project was constrained by budget, which didn’t allow for all ideal strategies to be implemented, the final design was able to achieve a satisfactory level of redundancy and resilience. Having a very high reliability on the normal power source allowed for a more cost-efficient standby power system, which focused on the most critical aspects of the facility.