A lighting upgrade saved a New York power plant money, plus upgraded its working conditions.

- The Luminant Independence Power Plant upgraded its outdated lighting system with advanced LED high-bay fixtures to improve energy efficiency, reduce maintenance, and enhance workplace safety across its 83,700-square-foot facility.

- The new lighting not only boosted illumination levels dramatically — raising foot-candles from as low as 0 to as high as 86 — and also incorporated controls for additional energy savings and improved operational visibility.

At the Luminant Independence Power Plant in Oswego, New York, roughly 35 miles north of Syracuse on the southeast shore of Lake Ontario, the energy plant wanted to take advantage of the latest LED technology when replacing fixtures that covered approximately 83,700 square feet of the general plant area with multiple floors and different types of spaces including around the facility’s water box, condenser and oil purification skids.

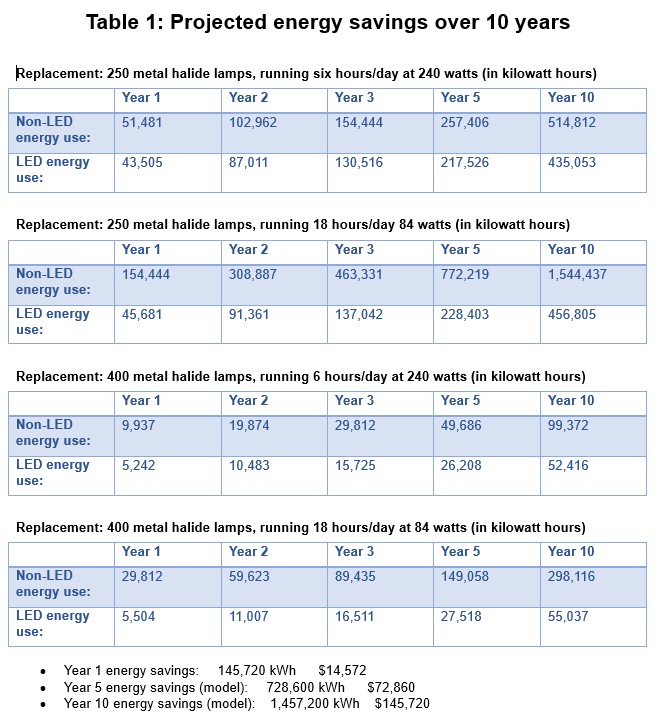

The goal of the LED retrofit completed in early 2024 was twofold — to save energy and provide a safer, more conducive working environment for the plant, which is open 365 days a year. The current fixtures were highly inefficient; many of them were 400-watt metal halide and nearly 30 years old. As a result of their advanced age, the fixtures required more maintenance than just re-lamping, including the replacement of ballasts and capacitors which required more time and manpower.

According to Rob Godden, Maintenance Technician at the Luminant Independence Station, the plant had established strict goals for the project, including brighter illumination, less maintenance time and more kilowatt hour savings. In addition, the team wanted to create a safer work environment.

“Safety actually involved two considerations,” said Godden. “First, some of the fixtures were hard to reach, which put people re-lamping in an unsafe situation. Second, we realized that just having better overall light in the area would make our facility safer for working.”

Specifying lighting and controls

Hal Duell from Power-Flo Technologies in Syracuse was brought in to lead the lighting project. He provided the plant with several different types of high-bay fixtures to test, including LED UFO high-bay fixtures.

After thoroughly investigating several options, Godden and his team specified wattage and color-correlated temperature selectable UFO high-bay fixtures from EarthTronics, Norton Shores, Michigan. The wattage adjustable and color selectable LED high-bay fixture was specifically developed to deliver energy savings by replacing up to a 1,000-watt high-intensity discharge fixture. The adjustable UFO high-bay fixture can be set at 150 or 240 watts, producing up to 20,250 and 32,400 lumens, respectively. It features color selection options of 3,500, 4,000 or 5,000 Kelvin with an 80+ color rendering index, providing visual acuity for accuracy when working in manufacturing and warehousing applications.

Intertek ETL Sanitation listed, each high-bay fixture is IP65 rated for wet locations and the housing is corrosion resistant die-cast aluminum. It has a 0 to 10 volts dimming standard and are compatible with several advanced control systems. Each fixture covers a 30×30-foot space with mounting heights varying from 14 to 25 feet.

In addition to realizing all of these benefits, the Luminant team was surprised by the incredible increase in foot-candles (fc) on the facility floor.

Energy savings through lighting

“After the installation of the new lighting, we measured four different work areas around the plant,” said Godden. “We found that the foot-candle increased from 6 to 42 fc; 0 to 24 fc; 2 to 48 fc; and 2 to 86 fc. As a result of the improved lighting, we have received numerous positive comments from various plant staff including our plant manager, maintenance supervisor, operators, maintenance personnel, safety manager and contractors.”

For additional energy savings, advanced network control sensors were added to the UFO high bays. The sensors are set for 100% sensitivity. Full illumination is maintained for 30 minutes after the signal is triggered. After 30 minutes of no activity, the light output is reduced to 35% for an infinite amount of time until the sensor is triggered again.