Designing domestic and fire water systems for buildings that have master plans for future high-rise comes with unique considerations and challenges that impact the booster pumps installed and ensure a future-ready, reliable solution to serve growing communities and services.

WSP USA Buildings designed a new patient tower at the Medical City Arlington campus in Arlington, Texas. The campus master plan included a new nine-story tower, but the initial design was for a three-story tower ready for eventual future vertical expansion. The tower was planned to be served by both types of equipment in a new central plant and extensions of other existing utilities. Considerations for both the existing campus and future expansion were needed throughout the design process to provide a cost-effective, future-ready and reliable design to continue to serve the community.

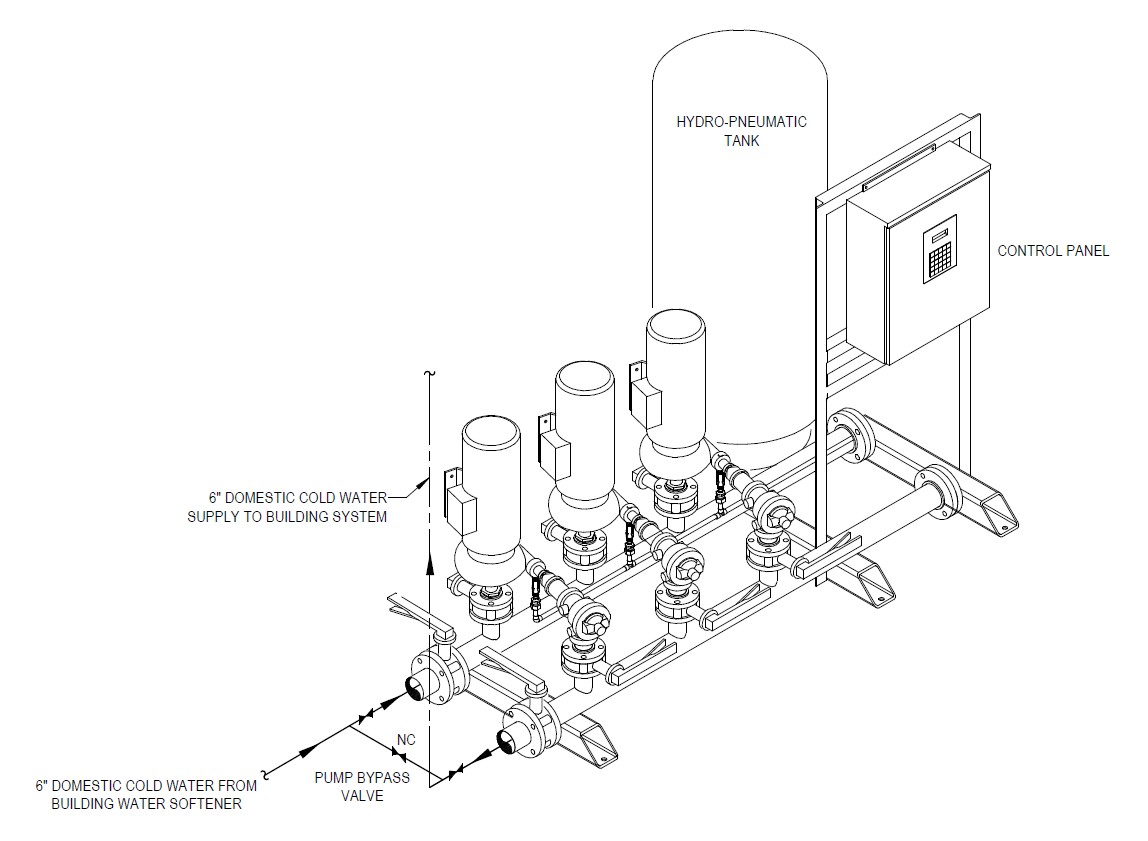

For the domestic water system, the team needed a flow test performed to set the baseline of available water pressure on the site. Considering the nine-story plan, the highest required pressure was 40 psi at the top occupied level to accommodate a flush valve water closet. Pressure calculations proved that the pressure at the lowest level would exceed the allowable pressure at a plumbing fixture, so separate pressure zones needed to be considered.

WSP USA Buildings decided to split the total nine-story tower into two parallel pressure zones. Because the vertical expansion accounted for most of the total building square footage and domestic water demand, two separate zones with separate booster pumps were best suited for the project. Two pressure zones allowed for a smaller flow and lift demand for the booster pump, adaptability for the future booster pump, available pressure, and design flow rate in the future, and a lower first cost for equipment to serve the current building. Levels 1 through 5 were put in a low-pressure zone, and levels 6 through 9 were put in a high-pressure zone. The pressure zones provided flexibility for some vertical expansion that could be served from the low-pressure zone equipment installed with the current project.

Because the total building was a nine-story tower, parallel pressure zones were possible. In high-rise buildings with more than 20 stories, it is often necessary to provide pressure zones in series. When pressure zones are designed to operate in series, it is important to provide an adequately sized hydroaccumulator or break tank for one pump to feed into and the other to pull from and serve the higher stories. The lower booster pump serves the lower stories of the high-rise building, and the higher booster pump is located at a higher level in the building. This strategy limits system pressures to ensure pipe material performance and safety.

Once the pressure zones were established and the design pressures were known for each level of the building, WSP USA Buildings selected the type of booster pump best suited for the project. The new domestic water equipment was planned for installation in the new tower, so space was a consideration but not constrained by existing conditions. WSP USA Buildings scheduled an expandable multistage booster pump skid assembly and provided space for a separate booster pump to be installed in the future. In addition, the pumps were selected to share the load equally, so pumps can be easily replaced as needed with only one pump size to order.

Both the current and future booster pumps need to consider the following sources of pressure loss as the main water utility serves the building. The water entrance includes two six-inch water services, a meter and two parallel backflow preventer assemblies in the building. The water service main is then routed to a pressurized storage tank with capacity for the future patient beds and an expandable water softener. The water softener assembly then supplies the current booster pump. Connections were installed for the future booster pump to also be served from the water service downstream of the water softener. With this equipment design, both booster pumps experience the same pressure loss downstream of the water entrance and can then boost the pressure as required for each pressure zone.

The fire pump for the Medical City Arlington project was also designed for the future vertical expansion. WSP USA Buildings selected an end suction single-stage horizontal split case fire pump with a capacity to provide 100 psi at the level 9 roof, so no replacement is required with the vertical expansion. Because the required pressure at the roof created a system that exceeded the maximum allowable pressure, pressure-reducing valves were provided on levels 1 through 3 and will be provided for future floors.

While the Medical City Arlington tower project is still under construction, WSP USA Buildings designed a system with future vertical expansion, ease of maintenance and flexibility in mind. The current project scope, existing conditions, and timeline of the significant future expansion all contributed to WSP USA Buildings’ design decisions for the booster pumps for this specific project.