Development and operation of the combined heat and power district heating system in Jamestown, N.Y., provides energy efficiency, environmental and economic development benefits to customers

Learning Objectives

- Learn about planning and successful gradual implementation of a community district energy system.

- Discover the parts of the combined heat and power plant, the transmission and distribution network and the participating buildings and customers.

The city of Jamestown, N.Y., began providing electric service in 1891, and in 1923 established a municipal power system, the Jamestown Board of Public Utilities. The single-purpose Carlson Generating Station was selected by Joseph Technology Corp. in 1984 as the central energy source for the Jamestown combined heat and power system. The power plant at this time included two steam driven turbine-generator units (No. 5 and 6), both with General Electric nonreheat turbines.

Unit 6 was selected for CHP modification in 1984 considering its relative ease of retrofit to cogeneration. This turbine is a 25,000 kilowatt, 3,600 revolutions per minute, 15-stage single-flow condensing unit, designed to operate at 850 psig steam pressure, 900°F temperature and 3.5 inches of mercury condenser pressure. The turbine had one blanked-off extraction point at the 11th stage from which it was decided to extract steam for use in a new district heat exchanger.

Higher loads were served with the existing auxiliary heat exchanger that was arranged in series with the new district heat exchanger (see Figure 1). After unit conversion to CHP operation, the efficiency of the turbine increased by 20%.

Figure 2: Shown is the repowered power plant, in which the gas turbine was coupled with the heat recovery steam generator. Courtesy: Joseph Technology Corp.[/caption]

Transmission and distribution network

The prefabricated piping conduit system consists of a thin-wall carbon steel carrier pipe, polyurethane insulation, polyethylene casing and a leak detection system. The district heating piping is installed in shallow trenches requiring minimal excavation and no shoring.

The design philosophy for the building retrofits is based on the following considerations:

- A plate-type heat exchanger was used in each building to transfer heat from the district heating water supply to the building distribution system.

- The district heating water supply temperature varies according to outdoor temperature.

Existing steam and condensate piping, wherever possible, was used to form a closed hot water loop, with the installation of circulating pumps, expansion tank and air removal system. All steam traps were removed and air vents were installed at system high points.

Conversion of a gas-fired hot air heating systems involved installation of a new hot water heating coil in the return air duct, along with an associated plate-type heat exchanger and closed loop hot water circulating system.

System development

The successful development of Jamestown CHP/district heating system was the result of the strong support from the community, the city administration, the board of public utilities and New York State Energy Research and Development Authority and the technical expertise and well-orchestrated effort of the consulting engineer, Joseph Technology Corp. The overall cooperation and strong community support for the project enabled local officials to enthusiastically promote the system, to obtain financing and to meet an ambitious construction schedule.

The objective of phased implementation was to develop the system in stages, spreading the capital expenditures in incremental investments over the development period and allowing the system to generate revenues to offset the capital investment. The system was developed in three phases, starting with a pilot system in the first phase, a core system in the second phase and continuous annual growth in the third phase. The system currently services 75 customers (see Figure 3).

The installation of the pilot system created a public awareness, which, coupled with the marketing activities, replaced the initial skepticism with enthusiasm for district heating and its benefits. The marketing aspects of system development in the city of Jamestown involved the combined efforts from the mayor’s office, the board of public utilities, other city officials and the consulting engineer.

Numerous public and private meetings were scheduled with prospective core customers to educate them and discuss the advantages of district heating for their buildings. A marketing campaign through public and private organizations, newspapers/magazines, radio and television was used to establish a public consciousness and acceptance, offering evidence through the operation of the pilot system.

The existing structure of the board of public utilities presented a unique opportunity for the city to institute a district heating system that is fully responsive to the interest of the city, with only limited additional procedural, administrative and managerial costs. Important factors in the selection of municipal ownership included the federal and state tax-exempt status and the customer acceptance and trust of municipality.

System economics

The positive economic analysis results served as the cornerstone for the development of the Jamestown system. The economic analysis was performed from the viewpoint of municipal ownership, using its distinct advantages. The operating expenses comprise replacement electricity costs, pumping costs, operations and maintenance personnel, O&M materials and steam costs. The replacement electricity cost is charged against the district heating system to compensate for the reduction in electrical output caused by the district heating steam extraction requirements.

It was recognized that during initial major capital investment years, the cash flow will be negative and breaking even when a critical number of customers were connected. Figure 4 presents the net operating income of the district heating system during the system existence over approximately 35 years.

In the context of municipal ownership, the normal source of funding for a district heating project is obtained through the issuance of long-term revenue or general obligation bonds. The phase one development of the Jamestown district heating system, involving the institution of a pilot system, was financed with short-term bonds. The later phases were financed with long-term bonds, including the refinancing of the first phase.

CHP system benefits

The system benefits include customer savings, environmental advantages, demand-side management application and potential for city economic revitalization.

The savings of district heating customers versus the self-generation cost of heat is 30% on average. The savings rate increases with any increase in the price of fuel. Customer savings are expected to rise in the future as the system grows with minimal capital investment.

In addition to economic development benefits, the city of Jamestown receives from the district heating system annual contribution in lieu of taxes. For the history of the system, the city has received from the system revenue about $2.2 million in lieu of taxes.

The resulting fuel efficiency of the system resulted in lower emissions and consequently reduced environmental pollution. The continuous and efficient operation of the CHP plant reduces the carbon monoxide and hydrocarbon emissions, which are characteristics of incomplete combustion by customer boilers. To date, 135 individual boilers have been shut down by the customers that were connected to the system.

The system resulted in reduction of electric peak load of the electric utility. Existing customers with electric heating systems were converted to hot water and connected to the district heating system. This application was significant for the city of Jamestown, considering the winter peaking characteristics of the electrical utility.

Future expansion

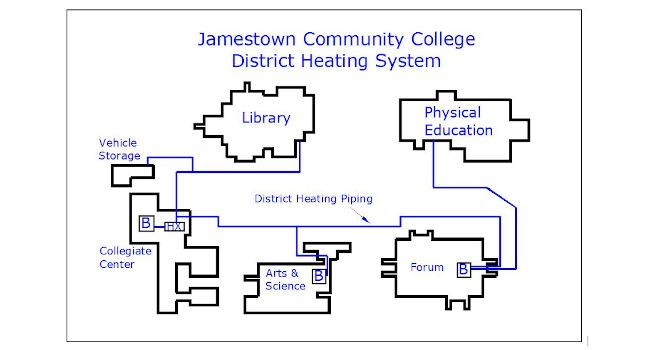

The system has been expanded every year. During the past with help of the board of public utilities, the buildings of the Jamestown Community College (located 1.4 miles from downtown) were connected with piping into satellite district heating system (see Figure 5).

The successful development of CHP/district heating in Jamestown is the result of a well-coordinated effort, starting with the system’s conception to its operation and growth. The system was implemented in stages. A coordinated effort among the mayor’s office, the board of public utilities and the consulting engineer, produced an effective marketing campaign.

The system ownership and financing capitalized on the advantages offered by the municipal avenue. This enables the city to control the major sources of energy: electricity and heating. The municipal control of these energy sources is used as an economic development tool by the city to attract new business.