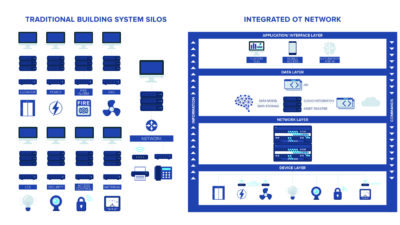

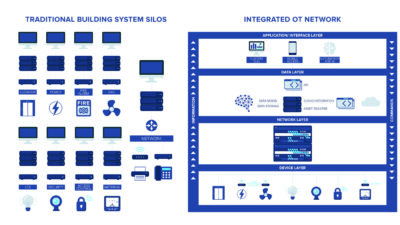

Engineered building systems technology is becoming more complicated and computer-driven. For these complex systems, the design engineer must get involved in the commissioning process—and remain so—to ensure that systems are integrated and function successfully. Traditionally, the term "commissioning" has referred specifically to system start-up.

Engineered building systems technology is becoming more complicated and computer-driven. For these complex systems, the design engineer must get involved in the commissioning process—and remain so—to ensure that systems are integrated and function successfully.

Traditionally, the term “commissioning” has referred specifically to system start-up. It has always evoked an image of a person out there in the field, energizing, pressurizing and operating electrical or mechanical devices—and then, testing and calibrating each component to assure system operation. It has also meant verifying that a strict lock-out tag-out system is in place to assure worker safety.

Certainly, these tasks are still a major part of commissioning requirements, during the installation and start-up phases of every project. Today, however, commissioning has taken on a new and broader meaning: It serves to confirm that systems are working as intended by the design engineer.

Building systems today are software-based, providing greater flexibility and reliability to the building owner. The owner’s staff may have a comfortable understanding of the building systems, but they might not be so familiar with the computer programming that controls them. Consequently, changes to software-based systems—editing reporting schemes, maximizing efficiency or adding modules—can be a problem.

Moreover, each manufacturer’s software may be different, and owners typically don’t have the time or expertise to gain a full understanding of software programming. Owners will feel most secure that systems are set and operating to design intent if the design engineer is involved in the commissioning process.

A thorough diagnosis

Hospitals and medical centers offer good examples of present-day commissioning. Healthcare facilities include complex systems not found in typical commercial buildings. And while industrial facilities also depend on complex systems, one major difference is that their maintenance personnel often receive specialized training on equipment and processes.

Hospital maintenance personnel, on the other hand, usually aren’t trained until the start-up phase of the building system. Moreover, they are trained on a wide range of complicated electrical, mechanical and communications systems.

Needless to say, the time frame, volume and intensity of training for health-care facility maintenance staff can be overwhelming, leaving them with only a hazy memory of each training session. They must trust that the system is operating as designed and as efficiently as possible—which, for many reasons, might not be the case.

The engineer writes a specification to meet the owner’s needs. If it is a performance-based spec, the requirements can often be met by several manufacturers, typically with proprietary software packages.

What often happens is that the contractor relies on the system vendor to determine the intent of the specifications, bid the job, and then, provide the necessary start-up. But the manufacturer’s field personnel might not have access to the specs. So, they may well program the system to operate similar to a previous job, or whatever the equipment vendor’s representatives are most familiar with.

With software-intensive systems, only sample performance testing —that is, commissioning—can assure an owner that the system they are receiving meets design intent.

Electrical systems, not only in healthcare but in all types of facilities, require particular attention. These systems require thorough testing, especially emergency generating systems, power monitoring and lighting controls. (For a checklist of items for commissioning of health-care facility backup power systems, see “Hospital Emergency” below; “Electrical Complex,” p.24, highlights the varied and complex power requirements of health-care facilities.)

Facility owners and managers must understand the complexity of these systems and the requirements of special training and start-up procedures to ensure effective system operation. For this reason, testing of each of these systems during the commissioning phase must serve as an education process for the owner.

Commissioning as education

In the best-case commissioning scenario, the design engineer witnesses the manufacturer’s training presentation to the owner’s staff, which would include a review of control routine iterations and change options. The meeting would take one or two hours per system, and everything would work perfectly. Of course, this rarely happens.

Knowledge is power, and knowledge of how power is being consumed in a facility comes from software-driven systems. When a project is completed, facility managers are left with pieces of software designed for specific applications. Should they wish to change, for example, a lighting control system, they may find themselves unable to do so.

This is why system testing during the commissioning must be used as an educational process for the facility operations and maintenance staff. In fact, the commissioning agent could go a step further and videotape these training sessions, which would offer two advantages:

Even if they have properly completed an extensive training program, the facility staff can forget the fine points over time; videotape can function as an operations manual and refresh the users’ memory when system modifications are required.

With a training videotape, new employees can spend time alone with the equipment, learning the procedures that were taught during commissioning. Videotaping captures invaluable question-and-answer interaction between facility personnel and the system trainer, a refreshing alternative to reviewing dry manuals. It also focuses on the important items to know when deciding to change a given parameter.

Naturally, to incorporate a successful building staff training program into the commissioning phase depends on the commissioning agent understanding what the staff needs to know. Consider, for example, key—and complex—engineered building systems that go into a health-care facility, how these systems require testing overseen on-site by the design engineer on the project, and how the owner can be taught to maximize their efficiency.

For example, in the era of electrical deregulation, understanding the power profile for a facility and where power is consumed within the facility is the first step to managing energy rates or negotiating a power contract. The power monitoring system should be networked to a central computer for monitoring power quality and consumption at each level within the facility.

But a power monitoring system is only as good as the owner’s ability to use it. Typically, a power monitoring computer is accessed only after a problem has occurred. The system should be geared to support all parameters the owner is interested in. The capability to trend electrical and HVAC parameters for each monitor is necessary to identify loads or to review any power quality issues. What might be necessary for the owner to understand when the maximum demand is occurring is a report that records maximum 15-min. amp demand over the last 30 days for each panel. This is also necessary for a better understanding of the panel capacity.

However, reports of this type are not in a typical reporting package and require special programming. Special reports should be tested by the engineer familiar with the intent of the report information. The accuracy of the user screens and reports, as well as the ease of moving between screens, needs to be confirmed.

The problem is that many of the screens or special reports are programmed by software engineers who are without a complete understanding of the intent of the design engineer or expectations of the owner. In that case, what is programmed may not reflect what was specified.

Planning from the start

Facility owners and design engineers must make sure that written contracts include proper testing of all systems for a facility. Specifications that relate to system commissioning should require that the contractor have the design engineer on-site for all specific system testing, using a wide variety of scenarios, including emergencies.

Why is the design engineer vital to the commissioning process? Because the person who designed the system and knows how it is supposed to work is the only one who can reliably confirm that it is operating correctly. But all too often, these systems are installed and started up at the end of the project, pushing up against a project deadline when coordinating an on-site meeting of contractor, owner, manufacturer’s rep and design engineer is a difficult task. This phase of the project is most compressed.

As the commissioning process increases in complexity, it is reasonable that it should be recognized, and budgeted for, as an important additional service in the contract agreement.

Educating the owner

Ideally, when all the above-mentioned parties are present for the commissioning process, the owner can receive the most productive training. It is also an opportunity for the owner to review the design philosophy with the design engineer. If this step is omitted, owners may only receive confusing software manuals for their new, advanced controls systems. These software manuals usually require a significant degree of study to understand—even for the manufacturer’s rep. When owners have purchased systems they don’t understand, their facilities may not operate as efficiently as designed, or tools may not be available to them that were specified.

Hospital Emergency: Commissioning Backup Power

Virtually all health-care facilities use emergency generators for backup power. When redundancy is desired—typically in large facilities—generators are paralleled to a common bus. The paralleling switchgear bus feeds the emergency side of the automatic transfer switch (ATS). Upon loss of utility power, all generators start and synchronize to the emergency bus to carry the hospital emergency load in less than 10 seconds. The ATS transfers in a prioritized order as required by National Electrical Code (NEC) 517.

NEC is very specific about the priority of life-safety, critical and equipment branches of the emergency system. The prioritized loading and unloading is typically included in the specification. Commissioning items that should be witnessed by the consulting engineer with the owner’s staff include the following:

Load Priorities. Confirm that priorities are assigned to each ATS. A vendor’s field service engineer might not understand the NEC requirements and may not even have access to a specification. In addition to the standard ATS in a facility, the designer may have included ATS dedicated to certain departments. Usually, the design engineer is most familiar with how all these ATS fit into the priority scheme.

Parameter Settings. Review all timed and calculated settings for transfer to emergency power and back to normal power, as well as generator optimization.

Device Identification. An understanding of how the external devices interact with the operation of the system may be required when troubleshooting problems. Labeling of devices, conductors and energized components will result in a more educated owner and safer system operation.

Annunciation. Understanding each annunicator panel—and what action to take when one is alarming—is important. For example, what action should be taken when the “generator offline” alarm is actuated? This may be a normal condition during maintenance, and it should be confirmed that the visual alarm stays on until the condition is back to normal.

Controls. Reviewing and operating each control switch and button gives the owner an opportunity to “kick the tires” and get familiar with the equipment.

Maintenance. All maintenance functions should be reviewed by the owner or a skilled maintenance person.

Special Functions. Functions specific to the installation should be tested to confirm that the owner is comfortable with them. Operations such as load banking, peak shaving, paralleling with the utility or auto transfer should be thoroughly tested. Faults should be simulated to assure the protective relays operate as intended.

Electrical and Lighting Complexity

Looking specifically at electrical power systems in health-care facilities, they require a reliable normal power source backed up by a dependable emergency power source for a variety of loads: heavy mechanical equipment; lighting and general purpose receptacles; and extensive low-voltage systems. Both primary and emergency systems provide power for sensitive electronics: computers, telecommunications, fire alarms and complex nurse-call systems. These electrical systems must also provide intense lighting for intensive care units and surgery, as well as power for physiological monitoring and telemetry, closed-circuit TV cameras and lighting, security and access-control systems.

Lighting control systems can do more than energize and de-energize lighting circuits via a time clock or photocell. Today’s lighting control systems are used to dim fixtures over preset times or dim or de-energize lighting circuits to save energy when daylight can be harvested. Do the ICU nurses want the corridor lighting dimmed during the night shift? The owners lighting control desires need are to be confirmed. Training the owner for different lighting control schemes is also important so that he can meet the needs of each department. As they settle into their new light-controlled spaces, the personnel of various departments will inevitably require system adjustments. Integrating lighting control with life-safety and critical systems also needs to be confirmed.