Understand contrasting approaches in a specialized microscopy building.

Designing a cryo-electron microscopy (cryo-EM) laboratory facility within a new building offers significant advantages over retrofitting an existing space, particularly given the complex environmental, mechanical and structural demands of high-resolution cryo-EM. Below is a detailed contrast between the two approaches.

Structural and spatial design

New building:

- Structural systems can be custom-designed to minimize vibration, with thick concrete slabs, isolated microscope foundations and strategic placement away from mechanical equipment, elevators or high-traffic zones.

- Room layout and adjacencies can be optimized for clean workflows, with logical separation between microscope rooms, prep areas, support labs and utilities.

- Ceiling heights, floor loading capacity and wall thicknesses can be specified to accommodate heavy equipment, acoustic dampening and future growth.

Existing building renovation:

- May face structural limitations, such as inadequate slab thickness or proximity to vibration sources (HVAC units, mechanical shafts or roadways).

- Retrofitting for required floor loading or vibration isolation often demands costly and invasive construction, such as floating slabs or spring-isolated platforms.

- Space constraints may force compromises in laboratory room size, adjacencies and equipment access pathways.

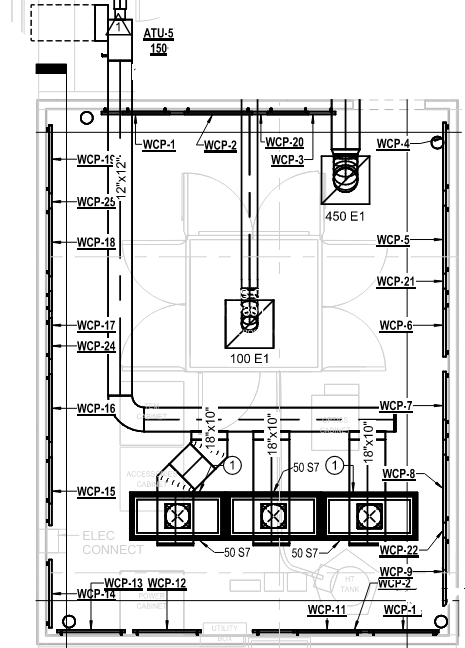

Mechanical, electrical and plumbing (MEP) integration

New building:

- HVAC, electrical and plumbing systems can be purpose-built with dedicated zones for cryo-EM, allowing for tailored airflow, humidity control and redundant power systems.

- Duct routing, mechanical room sizing and noise mitigation can be integrated from the start, reducing the risk of acoustic and electromagnetic interference.

- Easier to implement energy-efficient and scalable MEP systems with central monitoring and control.

Existing building renovation:

- Existing HVAC infrastructure may be undersized or poorly located for cryo-EM laboratory needs, requiring major rework to meet humidity, temperature and airflow tolerances.

- Routing new ductwork or electrical conduits in occupied spaces can be logistically complex and disruptive.

- Space limitations in utility corridors or mechanical rooms may prevent installation of high-capacity or redundant systems, increasing risk of failure.

Vibration mitigation in a laboratory

New building:

- Site selection can consider low-vibration zones (e.g., away from roads, subways or other mechanical sources), and slab design can incorporate vibration isolation from the outset.

- Electromagnetic and acoustic shielding can be built into walls and ceilings during construction.

- Utilities like chillers or air handlers can be strategically located far from microscope rooms to minimize interference.

Existing building renovation:

- Often located in mixed-use environments with higher background vibration and electromagnetic interference levels.

- Shielding and isolation may require extensive retrofits, such as radio frequency shielding rooms or heavy acoustic treatments.

- Some interference sources (e.g., elevators, electrical risers) may be impossible to relocate or isolate fully.

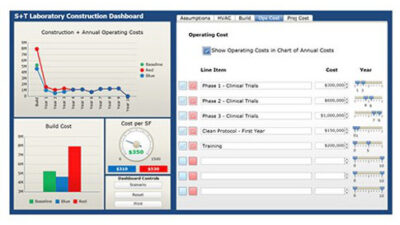

Laboratory construction efficiency and cost

New building:

- Construction sequencing can be planned for the cryo-EM suite without disrupting occupants, enabling a cleaner, faster and more efficient buildout.

- While upfront costs are high, purpose-built infrastructure is often more cost-effective in the long term, due to fewer compromises and lower retrofit costs.

Existing building renovation:

- Typically, lower initial cost than new construction, but hidden costs, such as demolition, unexpected utilities or unplanned upgrades, can quickly escalate.

- Work must often occur during off-hours to avoid disruption, prolonging schedules and increasing labor costs.

- Downtime and coordination challenges can affect adjacent lab operations.

Final engineering decisions

Designing a cryo-EM facility in a new building allows full control over environmental, structural and MEP systems, ensuring optimal conditions for high-end microscopy. It supports long-term scalability, performance and reliability. Conversely, renovating an existing space can be feasible, but involves significant engineering compromises, cost uncertainty and operational challenges. For institutions prioritizing cutting-edge research and facility longevity, purpose-built construction is often the preferred path. Retrofits may serve smaller-scale or interim needs with careful planning and mitigation.