Engineers should get involved early in the selection of the optimal power system for emergency lighting systems.

Learning Objectives

- Know the key considerations of emergency lighting design, which involves lighting levels, means of egress, codes, and the AHJ.

- Understand when and where an emergency lighting system is required, what the applicable code is, how it must perform, how it will be powered, and what the typical emergency lighting options are.

- Understand the emergency lighting system in the context and as an integral component of a building’s life safety strategies and technologies.

Through the last several years, challenges associated with emergency lighting have diminished due to comprehensive code development. Cross references between multiple building codes have been refined to minimize contradictions and subjective interpretations. Nevertheless, it behooves the engineer to be involved early with development of conceptual lighting schemes, determination of appropriate codes, and selection of the optimal power system for emergency lighting, not least of which is seeking the input of the authority having jurisdiction (AHJ) prior to submission of the permitting plans for approval. The AHJ interpretation of a specific code application ultimately trumps the professional engineer’s understanding.

Code requirements, applications

The primary codes used to determine proper application of emergency lighting systems include: International Building Code (IBC), NFPA 101: Life Safety Code, NFPA 70: National Electrical Code, NFPA 110: Standard for Emergency and Standby Power Systems, NFPA 111: Standard on Stored Electrical Energy Emergency and Standby Power Systems, and NFPA 99: Health Care Facilities Code. Determining which year a specific code or standard has been adopted by the jurisdiction where the given building project is located is critical prior to proceeding with emergency lighting design, as not all jurisdictions are enforcing the most current code or standard.

The engineer’s traditional responsibility for illuminating egress paths has been somewhat subordinated by the architect, who is responsible for the building design and determining building type. Further, the architect, in most jurisdictions, generally is responsible for defining the means of egress via the exiting plans. Typically, these exiting plans are subject to approval of the AHJ prior to issuance of a building permit and definitely are required prior to a building occupancy permit. The key stipulation for adequate egress lighting falls under the engineer’s purview once the official egress pathway has been defined.

The prime directive of IBC Section 1006.1 stipulates the means of egress shall be illuminated at all times the building space served by the mean of egress is occupied. By definition, egress is a “continuous and unobstructed path of vertical and horizontal egress travel from any occupied portion of a building or structure to a public way. A means of egress consists of three separate and distinct components: the exit access, the exit, and the exit discharge.” A number of jurisdictions include after-hours cleaning crews in consideration of a building being occupied, so lighting controls for means of egress must function automatically whenever the building is occupied.

NFPA 101: Life Safety Code takes all of the ambiguity out of emergency lighting process and provides clear expectations of the outcomes. Consequently, the initial code source for determining the proper application of emergency lighting is located in NFPA 101 Chapter 7. Emergency illumination is required for buildings as stipulated in Chapters 11 through 43 of this code. Section 7.9.1.2 clarifies that emergency lighting is only required for the purpose of exit access, which includes only designated stairs, aisles, corridors, ramps, and escalators to a defined public way. Obviously, these spaces must clearly be annunciated early in the design process in order to provide an emergency lighting system that can comply with the following performance requirements as specified in sections 7.8.1.1, 7.8.1.2, 7.8.1.3, 7.9.1.3, and 7.9.2.1.

The key parameters for emergency lighting as defined in NFPA 101 are the requirements for stairs to have a minimum of 10 fc (108 lux) measured at the walking surface, and a minimum of 1.0 fc (10.8 lux) for floors and walking surfaces with an exception for assembly occupancies of 0.2 fc (2.2 lux) during periods of performances or projections involving directed light (a movie theater).

In the event of a power outage, the emergency lighting must be transferred to its alternate source within 10 sec. Additionally, battery-powered emergency lighting shall be continuously available for 1.5 hours after the power outage. The emergency illumination shall be spaced to provide initial illumination along the defined path of egress of not less than an average of 1.0 fc (10.8 lux) and not less than 0.1 fc (1.1 lux) at the floor of the defined pathway. At the end of 1.5 hours, the illumination levels are permitted to decline along the path of egress as the emergency power source discharges to an average of 0.6 fc (6.5 lux) but not less than 0.06 fc (0.65 lux). In order to provide sufficient contrast and subsequent visual acuity, the maximum to minimum illumination uniformity ratio shall be no greater than 40:1.

Interestingly, the IBC 2012 is somewhat contrary to NFPA 101, stipulating in IBC 1006.2 the following: “The means of egress illumination shall not be less than 1 fc (11 lux) at the walking surface.” Note that this stipulation does not say “average” nor does it imply an average number; it is clearly the minimum requirement for emergency egress lighting, and is required by some AHJs. The exception to this applies to certain assembly occupancies. Fortunately, the performance of the emergency lighting system is the same in both the IBC and NFPA 101. Ultimately, the challenge presented is getting the AHJ to accede to the NFPA 101 requirements in lieu of IBC 1006.2, which certainly offers more specific parameters than can readily be achieved.

Completing a comprehensive code analysis is necessary to address specific emergency lighting applications for a given building type and jurisdictional requirements. For example, in addition to IBC building general type classifications, the IBC Type I-2 for hospitals have additional emergency lighting requirements as outlined in NFPA 99, NFPA 110, and NFPA 70 Article 517.63, which require supplemental battery-powered emergency lighting for anesthetizing locations. Further supplementary battery-powered emergency lighting is required for both normal main power and emergency main power switchboards. This requirement is codified in NFPA Article 110-7.3. The minimum horizontal footcandles shall be 3.0 fc (32.3 lux) at the floor level.

NFPA 101 Article 7.9.3 requires emergency lighting systems to have periodic functional tests. The functional testing is to be conducted monthly for a minimum of 30 sec, with an annual functional test of 1.5 hours required for battery-powered systems. The key constituent of this requirement is the maintenance of written documentation confirming the mandated monthly and annual functional testing visual inspections. NFPA 101 also allows self-testing and self-diagnosis as long as the self-testing is compliant with the manual requirements. For emergency lighting systems where self-testing is computer-based, a computer-generated report detailing the history of the tests is adequate for AHJ review.

Exit signage is required by NFPA 101 Article 7.10. The two approved types of exit signs are internally illuminated and externally illuminated. We will discuss exclusively internally illuminated exit signs. The exit signs shall not be spaced more than 100 ft apart and must be readily visible in all directions from the exit access. Exit signs with internal battery-powered sources are to be periodically tested in accordance with Article 7.9.3 and are to conform to UL 924. An exit sign’s illumination level is permitted to decline to 60% after 1.5 hours of operation. Floor proximity egress path marking exit signs are required within 18 in. of the floor for various occupancies as detailed in NFPA 101 Chapters 11 through 43. The exit signs must comply with UL 1994: Luminous Egress Path Marking Systems and be approved for delineation of egress pathways. The system must operate continuously anytime the building fire alarm system is activated. Obviously, the intent is to provide a clearly identifiable path of egress if the pathway is filled with stratified smoke and the only viable means out is very low to the floor.

Energy codes

In consideration of energy codes and emergency lighting—and unless specifically prohibited—NFPA 101-7.8.1.2.2 and 3 will allow lighting controls in areas of means of egress. The switch controllers must be listed and have a fail-safe feature, the “on” function must provide a minimum of 15 minutes of illumination, the motion sensor must be activated by occupant movement, and the controller must be activated by the building fire alarm system, if provided. The energy-saving control devices shall not compromise the integrity of the emergency illumination system. Thorough review of proposed lighting control solutions along with the emergency lighting egress plans with the AHJ should preclude any undesirable project outcomes.

Battery-powered sources

The emergency egress illumination power sources have two distinct categories: battery-powered sources and an emergency generator.

Battery-powered sources must comply with NFPA 111. All of the battery-powered systems must comply with the UL 924 standard, which is consistent with NFPA codes and IBC.

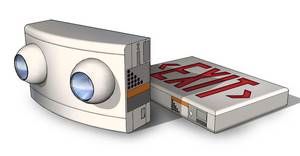

The most common battery-powered lighting source is a self-contained emergency lighting unit, which incorporates lamps in combination with a battery source and charger within a single enclosure. These units are sometimes referred to as either “bug-eye” or “frog-eye” units within the trades. Figure 1 depicts a typical self-contained emergency lighting unit. The units are generally powered by sealed, maintenance-free, lead acid batteries. These batteries have proven to be highly reliable and under most conditions need replacement at 7-year intervals. The units are circuited from an unswitched circuit, which supplies the local general lighting and turns on when the voltage serving the local general lighting drops to 80% of nominal. Upon return of normal power, the units will remain on for a minimum of 15 minutes.

Functional testing of these units can be accomplished via multiple methods. They include: an integral test switch; remote infrared handheld device, which one simply aims at the unit; and a factory-installed integral electronic device that automatically initiates code required tests. The automatic feature must produce an audible alarm with flashing LED if a test failure occurs. One can presume that if the unit is not in alarm and the device is UL listed for self-testing, then the testing requirement is satisfied and sufficient for the AHJ. Witnessing the actual test is not required along with the documentation. The critical design concern for bug-eye placement is to maintain a minimum of 1.0 fc along the entire length and width of the designated pathway of egress.

Some of these self-contained units have sufficient power to accommodate exit lights and remote lamp heads, which can be located adjacent to legally required exterior pathways to provide required emergency illumination levels. Exit signs must comply with UL 924 for luminance and with the AHJ for sign color and lettering size. The requirements vary among jurisdictions, so it is prudent to check the specifics before specifying exit signs. The two standard types of internally illuminated exit signs either internally house a powered source of light or are self-luminous signs. The most common type internally houses a source of illumination, either LED or fluorescent lamps. Both of these lighting sources use sealed, maintenance-free nickel-cadmium batteries. Exit signs are unswitched and continuously illuminated. They will revert to their battery power when the normal power drops below 80% of rated voltage. All of the testing requirements are the same as self-contained emergency lighting units. Fluorescent exit signs are required to have two lamps by code, in case one fails. The fluorescent lamps have an expected rated lamp life of 20,000 hours. The LED sources use less energy than the fluorescent lamps and have an expected lamp life of 50,000 hours.

Self-luminous exit signs are either self-powered or energy-storage type. The self-powered luminous exit signs contain tritium gas and provide continuous luminance for a minimum of 10 years. The stored energy type of luminous exit signs uses a strontium oxide aluminate compound to store ambient light, releasing the stored energy when the ambient source is turned off. The estimated useful life is in excess of 20 years. Both of these sources are listed for use in hazardous locations because they do not require external power sources and pose no threat of ignition in a hazardous environment.

Should the aesthetics of a given space preclude the use of the “bug-eye” type of emergency egress lighting, the engineer can incorporate an emergency fluorescent power unit within the area lighting fixtures. The packaged unit is self-contained with a built-in battery, battery charger, and inverter. (See Figure 2 for a typical self-contained unit.) It can power a single fluorescent lamp within the area lighting fixture continuously at a rated initial output of 1100 lumens. The packaged unit must provide at least 60% lumen output after 1.5 hours. The unit must be connected to an unswitched circuit, which serves the area lighting fixture. The unswitched circuit is permitted to run in a common conduit with the normal power branch circuitry. All of the periodic functional testing requirements as outlined in NFPA 101 must be accommodated by each packaged unit. The self-contained units can be remote mounted from the lighting fixture served. These units are capable of illuminating several lamps contained in multiple light fixtures and have power capacities up to 250 W.

The most comprehensive battery-powered emergency egress system incorporates a lighting inverter system, which is UL 924 listed and can meet the 90-minute requirement. The larger scale inverters have built-in panelboards and serve the emergency egress lighting directly. Achieving adequate lighting levels is fairly straightforward (see Figure 3). Since inverters are used exclusively to serve emergency lighting, the circuitry of emergency lighting is segregated from normal power sources. The inverters can range up to 130 kVa in size. Because one typically is illuminating only about 0.15 W for the entire emergency egress lighting system, most inverters are 30 to 60 kVa. The batteries’ sizes are proportional to the kVa rating of the inverter.

Engineers should use caution when sizing the inverter because the amount of electrolyte contained in the batteries might require continuous ventilation of the space, since it exceeds 50 gal for unsprinklered or exceeds 100 gal for sprinklered buildings (NFPA 1: Fire Code Chapter 52). The purpose of this requirement is the possibility of excess hydrogen being generated during the recharging cycle. The environmental and location requirements are outlined in NFPA 111. The main requirement is that the inverter system must be installed in a room separate from the normal power service entrance over 1000 amp and greater than 150 V to ground. The room must be dedicated for the inverter; n storage is permitted within the dedicated space. Ultimately, the inverter location and space requirements must be approved by the AHJ.

A typical one-line is included for an inverter system referred to an emergency power supply system (EPSS) in NFPA 111 Appendix B (see Figure 4).

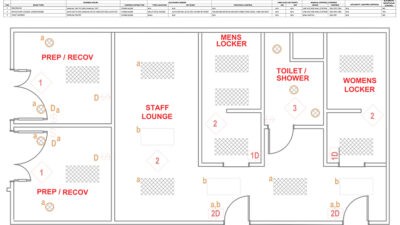

The emergency lighting inverter, when used in conjunction with selected luminaries, will provide more than adequate egress illumination. Figure 5 represents a computer-generated output of the expected photometric results based on the proper spacing of the designated emergency lighting fixtures for a medical college.

Generator systems

The second common emergency power source for emergency egress lighting is an on-site generator. The emergency power supply (EPS) and EPSS per NFPA 110 have various classifications and types stipulated in Chapter 4. This article is limited to Class 1.5 type 10, Level 1 EPSS.

Essentially, the generator is required to start and be on-line within 10 sec, and run for 2 hours. This is fairly standard requirement for most model codes; however, the run times vary in length based on the building type and use. The egress lighting levels and classification requirements are stipulated in NFPA 101. The requirement for automatic start and transfer is reiterated in both NFPA 70 and NFPA 99. The life safety circuitry must be segregated completely from the normal power sources. This was further clarified in the 2008 NEC (NFPA 70-700.9. (B) (c.)), where legally required systems (egress lighting) and optional standby power cannot originate the same vertical switchboard section, panelboard enclosure, or individual disconnect enclosure as emergency circuits. In the past, a generator could supply a common switchboard without the internal division for the automatic transfer switch (ATS) loads that supply life safety and standby power circuits. The loads and their respective ATSs supplied by the generator other than life safety must have load shed capability, to not endanger the life safety loads should the generator become overloaded, or have an alarm condition.

The required functional testing of the generators and their associated ATSs must comply with the requirements of NFPA 110 Chapter 8. The diesel generators are to be tested once a month for 30 minutes and loaded to at least 30% of their nameplate rating. Under certain codes the generator shall be annually loaded to 30% for 3 hours and then 75% for the last hour of the test. Obviously, all of the tests are to be witnessed and documented as are the associated automatic transfer switches transition modes. Figure 6 depicts a typical emergency generator with multiple automatic transfer switches.

The total solution

A sound understanding of the defined means of egress is critical for proper implementation of emergency lighting systems. Though the various codes and standards appear convoluted at times, there is consistency among their interpretation and cross-references. Once the applicable codes have been determined, one can navigate through the minutia and derive a viable lighting solution that will be suitable to the AHJ.

The key parameters of emergency lighting for means of egress are 1.0 fc average, 0.1 fc minimum, a uniformity ratio of 40:1, and 90 minutes of continuous illumination. If the building is occupied, it will likely require emergency egress lighting. All egress areas require more than one lamp that serves that area.

The most common sources of emergency lighting are a battery-powered packaged unit, a UL 924 lighting inverter, a self contained battery-powered packaged unit (bug eye), and a generator. Size, use, and classification of a given building are used to determine the most cost-effective solution for an emergency lighting system.

For certain building types, the emergency illumination system will be a hybrid system that will incorporate both emergency generators and battery-powered sources. Monthly testing and annual functional testing are not precluded for hybrid systems. Consequently, good documentation for each system will be required for the AHJ review and certification. The responsibility for record keeping ultimately is the building owner’s.

Thom Flickinger is a senior electrical engineer at Affiliated Engineers Inc. He has more than 30 years of design and project management experience in power distribution, information, security systems, distributed power systems, construction administration, and software development, serving the healthcare, research, higher education, mission critical, cleanroom, infrastructure, museum, and expo center markets.