System designers must interpret the requirements of NFPA 110, ensure their designs follow them, and educate their clients about how the standard affects their operations.

Learning objectives

- Understand which codes and standards dictate standby and emergency power systems, including NFPA 101, NFPA 110, and NFPA 70.

- Learn about the criteria for EPSS classification.

- Know how to better educate the owner concerning ongoing operational and testing requirements of NFPA 110.

Recently, an electrical contractor on-site at a mission critical project was having difficulties with the integration of the emergency lighting inverters with the power monitoring system. He looked at the large uninterruptible power supply (UPS) sitting adjacent to it and remarked about unnecessary pieces of equipment and why he should mess around with the pesky little 10 kW units when there were 2-MW generators supporting 800-kW UPS systems.

Surely, the contractor understands the differences in the code and listing requirements of the emergency and optional standby systems. However, his point was also clear. Due to the bulk of attention on and the much higher cost of the mission critical power standby system, it sometimes seems the emergency systems lag behind.

In this example, the life safety system was segregated from the standby system to simplify the overall system design and operation. It was also segregated to prevent the need to have the mission critical loads served from the same generator as life safety loads. That segregation was to simplify the overall power system while meeting the necessary codes. This article explains that decision-making process.

Reviewing applicable codes and standards

It is important to understand how different sources of information interact and affect the overall design of a facility. This information includes: codes, design and industry standards, and owner requirements.Understanding the individual sources of information provides a basis for understanding how to bridge the gaps between them, and it minimizes confusion and conflicts. This discussion focuses primarily on National Fire Protection Association (NFPA) codes, especially NFPA 110: Standard for Emergency and Standby Power Systems, 2013 Edition.

The following select codes and standards required to properly specify, design, and install emergency and standby systems typically involve these three primary areas:

- Installation and safety requirements, found in NFPA 70: National Electrical Code (NEC), 2014 Edition

- Selection of systems, found in NFPA 101: Life Safety Code, 2015 Edition and NEC

- Performance requirements, found in NFPA 110.

NFPA 101 defines the minimum requirements for equipment needed to support life safety systems, such as elevators, exit signs, and emergency lighting. This code relies on other codes, such as the NEC and NFPA 110, to provide information on how those systems should be installed and how they should perform.

The NEC is primarily concerned with installation requirements and safety. While it defines some operational requirements, it does not list specific requirements for performance, testing, or maintenance. In some places the codes overlap. For example, the NEC has requirements for emergency lighting to support certain types of installations, but it does not have specific requirements for when general emergency, exit signs, or elevator power are required to be on emergency power. The NEC also informs engineers about the overall system design criteria by presenting the different options as well as the minimum installation requirements.

NFPA 110 provides guidance on the performance, operation, and maintenance of emergency and standby power systems. Knowing how to apply it properly requires an understanding of the terminology used in the standard as well as its application.

NFPA 110, Chapter 3, Section 3.3.3 defines the electric power source for the emergency power system as an "emergency power supply (EPS)." This is the actual generator producing the power used by the system. Section 3.3.4 defines the overall standby system as the "emergency power supply system(EPSS)." The EPSS is the entirety of the emergency power supply to the load terminals of the transfer equipment.

Understanding EPSS classification criteria

NFPA 110 defines EPSS levels. Level 1 is defined as "where failure of the equipment to perform could result in loss of human life or serious injuries." This is typically interpreted as an emergency system in other codes, such as the NEC. Level 2 is defined as "where failure of the EPSS to perform is less critical to human life and safety." NFPA 110 further defines classification and types of EPSSs. NFPA 110,Section 4.2 defines classification as the amount of time, in hours, that the EPS is designed to operate atits rated load without being discharged or refueled. NFPA 110, Section 4.3 defines type as the maximum time, in seconds, that the EPSS will permit the load terminals to be without acceptable power.

The balance of NFPA 110 provides requirements for the two levels of EPSS. Included with the code are annexes that provide further guidance on the code’s intent. While this information is not considered part of the code’s language, it is useful to review to provide clarity of intent. Annex A is keyed to specific articles in the code, and Annex B provides diagrams of typical EPSSs.

Level 1 EPSSs are clearly defined. Per NFPA 110-A.4.4.1, Level 1 systems are intended to automatically supply illumination, power, or both to critical areas and equipment essential for safety of human life. This equipment includes: life safety illumination, fire detection and alarm, elevators, fire pumps, public safety communications systems, industrial processes where the interruption would produce serious life safety or health risks, and essential ventilation or smoke removal.

When a system is defined as a Level 1 EPSS, NFPA 110 triggers a number of requirements that must be considered during the design. Most of the requirements are simply good design practices. These include sizing the unit for ambient temperature and elevation, installation per the NEC and manufacturer’s requirements, and so on. Others include oversizing the fuel storage tank (Section 5.5.3), physically separating the EPS with a 2-hr fire rating from the rest of the facility (Section 7.2.1.1), and physical isolation of all EPSS equipment from the normal service equipment (Section 7.2.3). These concerns mayor may not be constraints, depending on the facility. However, they are always considerations for Level 1 EPSSs. Also included in NFPA 110 are operation, maintenance, and testing requirements, which are applicable to both Level 1 and Level 2 EPSSs.

The Level 2 EPSS designation more subtle. Per NFPA 110-A.4.4.2, Level 2 systems are intended to supply power to selected loads and are typically installed to serve loads that could create hazards or hamper rescue or fire-fighting operations. These include: heating and refrigeration systems,communication systems, ventilation and smoke removal systems, sewage disposal, lighting, and industrial processes. The list of equipment that, upon loss of power, could "create hazards" is extensive,which complicates this designation. This is further complicated by the need to determine if the standard actually applies to the system. NFPA 110, Section 1.1.3, item 6 states "equipment of systems that are not classed as Level 1 or Level 2 systems in accordance with Chapter 4 of this standard" are not covered by NFPA 110. This subtlety manifests by having similar systems in different jurisdictions having different designations.

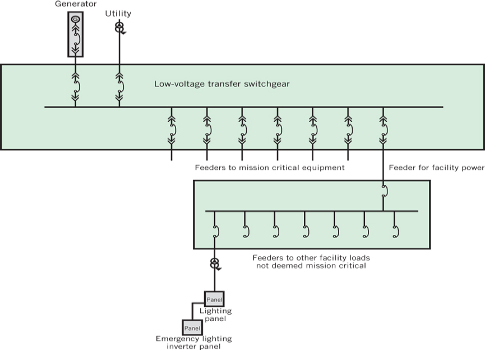

Equipped with the relevant code information, the installation discussed in the introduction can be analyzed. Figure 1 shows a high-level diagram of the system in question. In cooperation with the owner and the authority having jurisdiction (AHJ), the only load that requires an emergency power source(defined as Level 1 per NFPA 110) is the lighting required by NFPA 101. Other life safety loads (e.g., fire alarm) maintained their own emergency power supply and no other loads that were found to be life safety related. Due to economic and operational considerations, the owner wanted to provide optional standby generators for the entire facility. Based on coordination with the AHJ, this generation system fell under the category of NFPA 110, Section 1.1.3, item 6 and, outside the scope of NFPA 110. The system was installed as an optional standby system in accordance with NEC Article 702. The owner has worked with the manufacturer to develop a robust maintenance and testing schedule to ensure continued operation of the system.

By segregating the life safety loads and providing a source of power separate from the mission critical system, the overall electrical system was simplified. This also avoided any load shedding requirements where the mission critical loads would be shed to support the life safety loads, in accordance with NEC,Article 700. In the event that no generators were operational, the emergency lighting inverter would provide the emergency power to the lighting system. Similarly, a Level 1 generator could have been supplied in compliance with NEC Article 700 and NFPA 110, which would have accomplished a similar task.

Another example of a typical Level 1 EPSS is an emergency generator responsible for supporting emergency lighting, an elevator, and a fire pump. It is not unusual to also have that generator up-sized to support other loads designated by the owner. A system such as this would need to comply with all the requirements of NFPA 110 and the NEC to be a code-legal system, including multiple transfer switches to facilitate separation of life safety loads from other optional loads.

Mission critical loads fall in the optional loads category, despite being the primary driver for the system design. Most owners are not comfortable with an installation where the mission critical loads are dropped by design. This holds true for large-scale facilities that engineers envision when the term "mission critical"is used, but also smaller installations that have the same consideration. An example of this scenario is a smaller type of facility with a dedicated standby power system that supports select loads deemed critical to the continued operation of a business, or systems installed to protect inventory.

Mission critical facilities have standby systems-some very sophisticated-that can include UPSs, generators, and other standby power systems. These are typically classified as optional standby systems and are not related to human safety. Instead, these systems are related to the economics and overall business strategy of the owner. While these systems may meet many of the EPSS Level 2 requirements,the desire, generally, is to not designate these systems as an EPSS to allow the owner greater flexibility in the operation, installation, and maintenance of the system.

Figure 2 shows a large-scale paralleling generator standby system with an additional emergency generator for life safety loads. Depending on the mission critical loads being supplied and coordination with the AHJ, that system would be designated as a Level 2 EPSS or found outside the scope of NFPA 110.

As shown, the loads that require Level 1 and, where required, Level 2 EPSSs can be segregated from the mission critical systems, allowing the mission critical generation system to be outside the scope of NFPA 110. This can have both cost and constructability impacts. However, that’s not to say that NFPA 110 becomes superfluous. Certain aspects of NFPA 110 are commonly applied to mission critical projects in the form of best practices. These include record keeping, spare parts, and equipment testing. However,this differentiation allows the owner and engineer to choose requirements that seem reasonable without being required to comply with the code in its entirety.

Care should be exercised as either segregating or combining the various load levels can cause unforeseen consequences and, if not carefully managed, additional complexity. An example of this complexity can be seen by reviewing Figure 2. In the event of a power outage, all six generators start.Within 10 sec, the life safety generator is available to provide power to the life safety loads. The relevant transfer switches fire, and the life safety loads are fed from the life safety generator. Meanwhile, the parallel generator system is still in the process of powering up, synchronizing, and preparing to accept load, a process that can take up to 60 sec. When that process is complete, the parallel generator system closes its feeder breakers, feeding the entire distribution system. This includes the normal side of the emergency transfer switches. This situation should be thoroughly reviewed with the owner and AHJ to determine what should happen in this case and how to implement that decision.

This complexity can increase the risk of a generation system failure and an outage occurring, which could cause the mission critical or life safety systems to be impacted. It is possible to have emergency loads as well as mission critical loads supplied from that same system. However, the engineer should work with the owner, the operator, and the AHJ to ensure the installation and operation of that system is in accordance with all applicable codes, specifically NFPA 110.

Educating the owner

Furthermore, compliance with NFPA 110 does not stop when the design and construction of a project are complete. Chapter 8 of that code addresses the ongoing requirements for the owner (or, more specifically, the owner’s operations team) that must be addressed both to comply with NFPA 110 and,more importantly, to ensure the continued operation of the EPSS. Educating the owner to ensure proper operation of the EPSS should be started at the outset of the design and continued through construction,testing, and commissioning. Coupled with this education, it is crucial that the engineer understands the owner’s plan to operate, maintain, and test the standby system to ensure that the design and construction support that plan. This two-pronged approach can ensure that when all other parties complete their portions of the project, the owner is in the best position to be successful.

Chapter 8 of NFPA 110 specifically lists some of the ongoing requirements for maintenance and operational testing of the EPS and EPSS. Ongoing maintenance, testing, and documentation are required for both Level 1 and Level 2 EPSSs. The primary difference is certain items, such as general electrical inspections, are not required to be performed as frequently. As with most other NFPA codes, the items listed in NFPA 110 are minimum requirements. The manufacturer’s recommendations and written instructions should influence the developed maintenance and testing regime that is implemented.

While the maintenance and operation are not typically within the scope of services provided as part of an engineer’s design, NFPA 110, Chapter 8 can and should influence the design of the EPSS. Examples include:

- Requiring specialty tools or high mortality replacement items to be supplied as part of the procurement package of the equipment in question

- Specifying maintenance contracts as part of the vendor’s proposal for review by the owner

- Incorporating record-keeping requirements into an overarching building management solution

- Documenting the owner’s testing strategy and incorporating it into the design (i.e., temporary vs.permanent load bank).

NFPA 110 provides a list of items that are required to be considered as part of the ongoing maintenance and operation of the EPSS. These items should be reviewed with the owner early in the project so they can be incorporated into the facility design, if desired. Examples include a temporary generator being available when a generator is out of service and the stocking of recommended spare parts.

Whether the standby systems are designated as EPSS Level 1, Level 2, or not within the scope of NFPA 110, the owner, with support from the engineer, should work with the manufacturer of each piece of equipment to design a robust ongoing maintenance, testing, and documentation procedure. These procedures ensure ongoing reliability while preventing excessive wear and tear of the equipment. Due to the complexity of most mission critical power systems, the standby system should be tested and commissioned as a whole to ensure that no unforeseen interactions have manifested that could adversely affect the operation of the system as a whole.

Meeting expectations

Certain requirements-sometime competing-must be understood prior to beginning the design of any mission critical facility. NFPA compliance is certainly one of them, but the owner’s facility needs, budget,industry requirements, and constructability also should be considered. The better understood all the requirements and expectations are at the beginning of a project, and how they inform the overall design,the more thorough the design can be as it progresses.

This understanding of intent will then support the development of the construction plans and specifications with the obvious goal of delivering engineered documents that comply with the regulatory requirements and meet the owner’s expectations. These documents should support the construction and testing efforts and minimize changes that inevitably impact the schedule and costs, thus supporting the ultimate desire of delivering a mission critical facility that supports the owner’s business within the expected budget.

Jeremy Taylor is an electrical engineer at CH2M Hill. He has more than 10 years of experience as an electrical engineer in a wide array of projects, including multiple mission critical facilities ranging from small 50 kW generator retrofits to 15 MW data centers globally. He has been involved in the design,construction, and commissioning of those projects, supporting not only the electrical construction effort,but also the delivery of the facility as a whole.