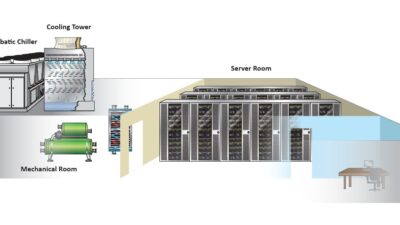

The IPC 9521 Integrated Plant Control system is designed to help building owners achieve energy efficiency in chiller plant systems and uses a base-level platform that can be easily upgraded as installation requirements evolve.

Armstrong Fluid Technology’s IPC 9521 Integrated Plant Control system is designed to help building owners achieve energy efficiency in chiller plant systems. The IPC 9521 uses a base-level platform that can be easily upgraded as installation requirements evolve. Features include a resident sensorless pump feedback and parallel sensorless pump staging for variable primary systems that minimizes installation costs and maximizes pump energy efficiency. It also has embedded sequences for water-cooled variable-primary configuration, all-variable chiller plant automation, and optimization. The IPC 9521 is factory configured for easy activation of the optional Armstrong ECO*Pulse HVAC health management and diagnostics system.

Armstrong Fluid Technology

www.armstrongfluidtechnology.com