How to select, design, and redesign lighting systems so they complement HVAC systems.

Learning objectives

- Understand how lighting choices affect a building’s overall energy efficiency.

- Discover key factors of lighting design that impact a building’s cooling and heating loads.

- Learn issues to consider when evaluating alternative lamp technologies.

Some federal, state, and city energy codes, standards, and guidelines now restrict building lighting power density (LPD) to as low as 0.60 W/sq ft. This restriction is requiring the architectural and engineering design teams to fully comprehend and evaluate the contribution of lighting to the building cooling and heating loads for retrofit applications. Designing lighting systems so that they complement the HVAC systems design to a net reduction in building energy use requires close interaction between the lighting designer, architect, and project mechanical and electrical engineers. It is the challenge of the team to develop a lighting layout that not only provides quality illumination to the space, but also reduces overall energy consumption.

One challenge the design team faces in developing a lighting strategy is to incorporate components that can be accurately modeled by HVAC cooling load and energy analysis software. With a renewed focus on sustainability and energy conservation, the financial support for product development in lighting technologies has spawned a wide array of new lamps and control devices available to design architects and engineers. However, performance data may not always be presented in an equivalent manner regarding energy usage and quality of light. As design teams take advantage of this new technology, it will be critical that correct comparable performance data be obtained and incorporated into not only building cooling and heating load analysis and energy modeling, but also into photometric software programs that allow the design team to study, test, and implement lighting designs.

According to the U.S. EPA Energy Star Building Upgrade Manual, lighting is typically the largest source of waste heat, representing approximately 35% of electricity consumed in commercial buildings. That waste heat translates into heat gain, which significantly impacts the building cooling and heating loads. Although other factors also influence the final cooling/heating load analysis, the lighting system contributes a major portion of internal heat gain. This internal heat gain, for certain climates or building configurations, can be useful when the building is in the heating mode. When the building is in cooling mode, however, lighting heat gain can be detrimental, due to the increase in the cooling load and the capacity of the cooling equipment required to maintain space thermal comfort conditions.

In many retrofit applications, reduced building lighting loads and corresponding reduction in the cooling requirement may result in reduced full-load operations of the HVAC systems. This can save significant amounts of energy used for lighting and cooling the building, lower energy cost and may prolong the service life of existing HVAC components. An additional benefit is that the resulting excess cooling capacity could be used to serve future cooling load requirements, provide redundant capacity for existing critical loads, or allow replacement cooling equipment capacities to be lower, i.e. right sized for the lower loads, further reducing operating expenses.

New energy codes and standards

In the past few years, several revised energy codes and standards have been released. Understanding the basic requirements of the standard applicable to the specific project is imperative in designing and modeling lighting systems that provide optimal performance and are cost effective on a lifecycle basis.

Recently implemented codes and standards that have an impact on the design of lighting systems for retrofit applications include the Energy Policy Act of 2005 (EPAct 2005), 2012 International Energy Conservation Code (IECC) and ANSI/ASHRAE/IES Standard 90.1-2010, the State of California 2013 Building Energy Efficiency Standards, Title 24, Part 6 (and Associated Administration Regulations in Part 1), and the City of New York City LL85: Energy Conservation Code and LL88: Lighting Upgrades & Sub-Metering Code.

These codes and standards as well as voluntary sustainability programs—such as the U.S. Green Building Council (USGBC) LEED certification program, the Green Building Initiative (GBI) Green Globes program, ASHRAE Standard 189.1-2011, and the U.S. EPA Energy Star program—represent a paradigm shift in the way architects and design engineers have to consider not only the initial impact of lighting in the calculation of heating and cooling loads, but also ongoing operating conditions and retro-commissioning of existing systems. In fact, some code authorities and the U.S. Army (UFC 1-200-02 High Performance and Sustainable Building Requirements) have adopted all or portions of these standards for some specific building types and/or locations within their jurisdiction.

For design team members, these changes highlight the importance of collaboration in selecting the lighting technology to employ on a specific project. Design of today’s energy-efficient and innovative lighting systems requires a total effort by the design team in evaluating alternative lighting system impacts on interior space planning, lighting fixture layout, furniture and fixed equipment layout, and lighting controls, resulting impact on HVAC cooling and heating loads, and ultimately the energy use and utility costs to operate the building.

Building configuration and load calculations

Calculating space cooling and heating loads requires many aspects of the building design to be considered. Factors that affect the heating and cooling loads include:

- Type of building

- Building configuration and floor area

- Wall to window ratio

- Building orientation on the site

- Thermal performance of the building envelope

- Impact of external shading devices or adjacent buildings

- Ground reflected solar radiation

- Climate conditions

- Indoor design requirements

- Internal heat gains, including plug and process loads

- Building occupancy schedules

- Energy consuming equipment operating schedules

- HVAC system types

- Sequences of operation of the HVAC systems.

For retrofit applications, engineers must know the size and efficiency of existing heating and cooling systems and how the building equipment is operated in order to accurately predict energy consumption and peak demand. Typically, large high-rise buildings are dominated by high internal loads, and consume more air conditioning and heating than most low-rise applications due to the size and density of the building occupants and equipment heat gain. According to the EPA, high-rise buildings present the best opportunity for energy savings. Each kWh of reduction in annual lighting energy use yields an additional 0.4 kWh of annual reduction in HVAC energy.

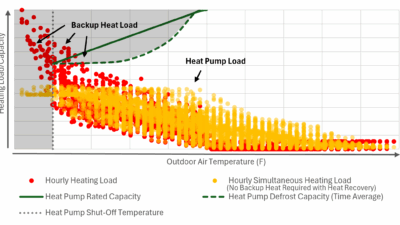

For smaller, exterior envelope-dominated buildings, the net impact of a lighting retrofit may result in a net HVAC penalty, particularly for buildings in cold climates. This means that for each kWh in lighting energy reduced, the building HVAC system net energy consumption may rise as a result of additional annual heating energy used. In other words, a reduction in lighting load may result in an increase in building heating load, which results in no net change or an increase in total energy consumption if the reduction in energy used for cooling is less than the additional heating energy required over the course of the year. Empirical data shows that or the majority of scenarios, lighting upgrades are more likely to reduce cooling costs and increase heating costs.

When calculating building cooling loads, the designers must consider the components that comprise the heat gain due to lighting. These factors can vary such that at any given moment, the heat equivalent of power supplied instantaneously to the lighting is not necessarily that which equates to the instantaneous cooling load. Of the three basic types of heat transfer, convection and thermal radiation are the major contributors to lighting heat gain while conduction is negligible. Both convection and thermal radiation transfer heat to the space, which results in 100% of the lighting power becoming cooling load. However, it is important to recognize that the convective component represents an instantaneous heat gain, while heat gain due to thermal radiation is delayed because the heat is stored within the surfaces in the room such as ceilings, floors, walls, furniture, etc. This is true for all types of lighting technologies (LED, fluorescent, incandescent, etc.), although the fractions attributable to radiation vs. convection will differ.

The 2013 ASHRAE Handbook —Fundamentals presents a detailed discussion of the various parameters which influence the calculation of cooling loads due to lighting heat gain. Of those presented, key factors encountered repeatedly in the new energy codes and standards are the fractions of heat gain and the special allowance factor (SAF).

The fractions of heat gain consider the assignment of the components heat output by the luminaire. Cooling loads typically account for heat generated by in-ceiling (or recessed) luminaires, which are made up of two key parameters:

- Ceiling plenum fraction: The fraction of the lighting power that heats the return air that is directed through the light fixture (zero for surface mounted and pendant hung light fixtures and task lights)

- Space fraction: The fraction of the lighting power converted to heat gain in the conditioned space.

In lighting retrofit upgrades for commercial office buildings, the design typically includes recessed fluorescent lighting fixtures, which will release heat to the space and direct heat to the return air plenum or to the ceiling cavity. It is important to distinguish these components even though total cooling load imposed on the cooling coil remains the same. The larger the fraction of luminaire heat output that is picked up in the return airstream for air return luminaires and directed back to the cooling coil, the better the overall energy performance and interior comfort due to the reduced fraction of heat that goes to the conditioned space. This channeling of the lighting heat to the ceiling plenum helps reduce the room cooling load, thereby reducing the supply airflow (and resulting fan energy) required for space conditioning.

The SAF is the ratio of lighting fixture total power consumption, including lamps and ballast, to the nominal power consumption of the lamps, which includes the luminaire lamps and ballasts (for fluorescent fixtures). As a reference, an incandescent lamp has an SAF of 1.0. To demonstrate the progress made in the development of energy-efficient fluorescent lighting over the past several years, an historical comparison is made between the 1977 and 2013 ASHRAE Fundamentals Handbook. In the 1977 Handbook, the SAF for fluorescent luminaires was as high as 2.19 for 32-W single lamp T-12 high-output fixtures. For a rapid-start 40-W T-12 lamp fixture, allowance factors vary from a low of 1.18 for two lamps to a high of 1.30 for one lamp. These SAF values accounted for the losses in the magnetic ballasts, then commonly used in the fixtures.

Recent ASHRAE research has found that the SAF ranges between 0.87 and 0.90 for T-8 luminaires with electronic ballasts and between 0.98 and 1.02 for with other lamp types. Electronic ballasts can lower electricity consumption below the lamps’ rated power requirement, which represents a significant advance in lighting technology and provides a valuable tool for the designers reduce cooling loads and enhance energy performance. Electronic ballasts operate the lamps at a higher frequency (>20,000 Hz), offer additional controls options for lamps, and consume less power than magnetic ballasts.

The current ASHRAE Handbooks present little data on LED lighting, no doubt due to the rapid development in solid-state LED technology. However, a review of recently published manufacturers’ data for solid-state LED lighting indicates the SAF is further impacted to the positive when considering the light output per unit and quality of light provided to the object area.

Recent developments in solid-state LED technology show superior performance for both the space fraction and radiative fraction numbers. As compared to incandescent fixtures, the fraction of heat transfer due to radiation vs. convection is typically much higher for LEDs resulting in more of the lighting load being stored delaying its conversion to room cooling load. Also, because LEDs emit little or no infrared (IR) or ultraviolet (UV) radiation more of the radiated energy is in the form of visible light. Considering that not all published data on LED technology is equivalent at this time, the design engineer has to carefully evaluate data such that the values are normalized for proper input into the cooling load analysis and energy modeling software. It is necessary for the design engineer to calculate the heat generation performance for each component of the luminaire as a fraction of the total lighting heat gain by using judgment to estimate heat-to-space and heat-to-return percentages.

Reduction in LPD

For lighting retrofits in commercial office building spaces, the LPD load analysis should include all luminaires that are added, replaced, or removed. Lighting alterations that involve only the replacement of lamps and ballasts must also comply with the LPD requirements. This cooling load analysis should include the wattage of line voltage luminaires containing remote ballasts, transformers at the labeled maximum wattage of the luminaire, or the combination of values for auxiliary manufacturer’s literature or a nationally recognized testing laboratory.

In the case of lighting power calculations for ballasts with adjustable ballast factors, calculations for load impact should be based on the ballast factor that will be used in the space, provided the ballast factor is not user-adjustable. In commercial applications using specialty lighting for display or architectural purposes, such as line voltage track or plug-in busway, localized load impact should be considered in the overall load calculations.

Lighting controls

Updates to energy codes and standards have already caused the retrofit and new building markets to transition from less efficient lamps and luminaires to more efficient devices. Energy consumption can be further reduced by taking advantage of the new technologies to control lighting systems that use high-tech lamps and ballasts.

Automatic lighting controllers can dim or switch lighting based on time of use, occupancy, daylighting level, or a combination thereof. Lighting systems in commercial office buildings are often left on for long periods of time due to low occupancy in a space or a cleaning crew working into the evening. Having the ability to control lighting by turning off lights that are no longer required or that are left on in unoccupied spaces, or using daylighting when available can present additional energy saving opportunities. Some lighting control strategies currently being used by designers include:

- Vacancy or occupancy control (lights are turned on and off or dimmed according to occupancy)

- Scheduling (lights are programmed to turn on and off according to work schedules)

- Daylight harvesting (electric lights are automatically dimmed or turned off in response to the presence of daylight)

- Demand response (power to electric lighting is reduced in response to utility curtailment signals or to reduce peak demand power charges to a facility)

- Tuning (light output is reduced to meet the occupants’ needs)

- Adaptive compensation (light levels are lowered at night to take advantage of the fact that occupants need or prefer less light than during the daylight hours).

Improved power quality

Poor power quality is a concern in buildings because it wastes energy, reduces electrical capacity, and can harm building and tenant equipment. In some cases, it can negatively impact the building’s electrical distribution system itself.

Power quality is a condition of the power supplied to equipment. The power supply may contain transients and other short-term under- or over-voltage conditions that may result from switching operations, faults, motor-starting, lighting disturbances, switching of capacitors, electric welding, and operation of heavy manufacturing equipment that may contain harmonic content. Harmonics are integral multiples of the fundamental (line) frequency involving nonlinear loads or control devices, including electromagnetic devices (transformers, lighting ballasts) and solid-state devices (rectifiers, thyristors, phased-controlled switching devices).

Upgrading lighting equipment with new, high-power-factor and low total harmonic distribution characteristics can help improve power quality in an existing electrical system and possibly free up electrical capacity. In many cases this benefit can justify the cost of a lighting upgrade. For instance, the measured watts of low-power-factor ballasts are approximately the same as the measured watts of the high-power-factor (above 90%) type when connected to the same load. The low-power-factor type draws more current from the same power supply and, therefore, larger supply conductors may be necessary. The use of high power-factor ballasts permits greater loads to be carried by existing wiring systems. Many public utilities have established penalty clauses for the use of low power-factor equipment.

Daylighting

The use of natural daylight to provide up to 140 lumens (lm) of light compares favorably with the 90 lm/W from most electric lighting systems. Systems that take advantage of daylight to supplement electric lighting present one of the best ways to reduce building lighting energy consumption by balancing loads and peak demand and creating a more desirable indoor environment for occupants. In designing daylighting into a retrofit building condition, there are four basic criteria to consider:

1. Harvestable light: Amount of light that can be brought into the space for effective use via skylights, light shelves, clerestory windows, or light pipes.

2. Interior material and color impact: Balancing the use of specialized reflective materials and interior colors to use the light’s benefits.

3. Glare: Direct sunlight into a space can cause uneven luminance ratios that are distracting to the occupants and cause not only irritation, but also hot-spots in the space. Bouncing light or allowing diffuse daylight from certain exposures such as north, can aid in glare reduction.

4. Control of electric lights: For daylighting to be most effective, lighting controls are required to maximize performance. Automatic sensing control presents an approach that ensures electric lighting will be reduced when enough ambient daylight is available to illuminate the space. The application reduces the opportunities for over-dimming, under-dimming, and/or rapid-cycling of the lighting devices, thereby assisting in reducing the cooling load and energy savings.

Another daylight control opportunity is to enable the use of automatic window shade control as part of the space lighting plan. HVAC load analysis typically incorporates the benefit of window shading devices commonly modeled in cooling load analysis software programs. In calculating the value of daylighting benefit, items to be evaluated include the time of day, season, available light, and controls that can raise or lower shades to optimize daylight contribution.

Efficient lighting sources

With the advent of efficient lighting sources such as linear fluorescent lamps, solid state LEDs, and high-intensity discharge (HID) lights, it is critical to be able to assess the actual impact of the lighting device performance. The combination of lamp, ballast, and heat extraction fixtures helps maximize efficiency while balancing the considerations of lighting quality and quantity.

The designer has the option available to choose from a variety of types and manufacturers for each application depending on efficacy, color quality, and service life within the HVAC load analysis. Whenever possible computerized energy modeling can be used to assess the HVAC load components of a given lighting design allowing the designer to overlay and model the results of lighting performance within the designed space.

The use of light modeling software enables the architectural/engineering design team to preview the design of lighting within a BIM model and quickly understand the impact on the user space. In most cases more than one simulation may have to be developed to identify the optimal lighting arrangement for a space. Once the modeling layout is agreed upon by the team, load data can be imported to the HVAC load analysis program.

The importance of accurate cooling load analysis and modeling of lighting systems is key to optimizing overall HVAC system performance. Taking advantage of computer-based modeling and light simulation programs has enabled the design team to consider lighting options that can provide significant benefit to the project. New lighting technology, when incorporated with enhanced lighting control, does present potential initial increase in first costs to the project. However, it is incumbent on the design team to develop designs that ultimately provide financial benefit, on a life cycle cost basis, as well as HVAC system performance optimization while providing the occupants with a space that is comfortable.

David B. Duthu is board principal at ccrd, where he has more than 37 years of experience in the fields of mechanical engineering design, technical engineering design, and project management. Nolan Rome is associate principal and lead mechanical engineer for ccrd and has been responsible for the design of all types of healthcare facilities including hospital expansions, cancer centers, and imaging centers in multiple states.